The future of security in the automated factory

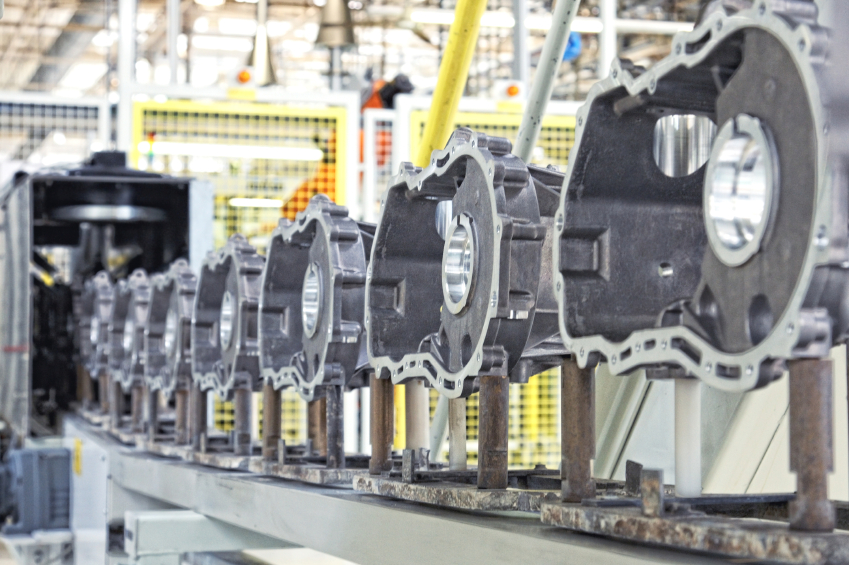

Wireless technology, the Internet of Things, and factory automation have come together in a way that has helped manufacturers collect more data, make adjustments, and see what’s happening on the factory floor from anywhere, as long as they have an internet connection. This convenience and access to information have revolutionized...