Intelligent factory automation systems are not composed piecemeal by updating one production step at a time. Rather, they require an end-to-end design, engineered so that each step flows seamlessly into the next. By engineering a complete assembly from start to finish, manufacturers can eliminate choke points and slow areas throughout their production line.

At Eagle, we bring the best of Industry 4.0 technology to bear on our assembly designs. We use simulation software to model how each automated piece will fit together, and use that data do deliver more accurate project estimates. Our team can then return to those simulations to get a jumpstart on automation programming while our build team creates the actual assembly. This process allows us to deliver higher quality products with a shorter turnaround time.

UNIVERSAL BASE

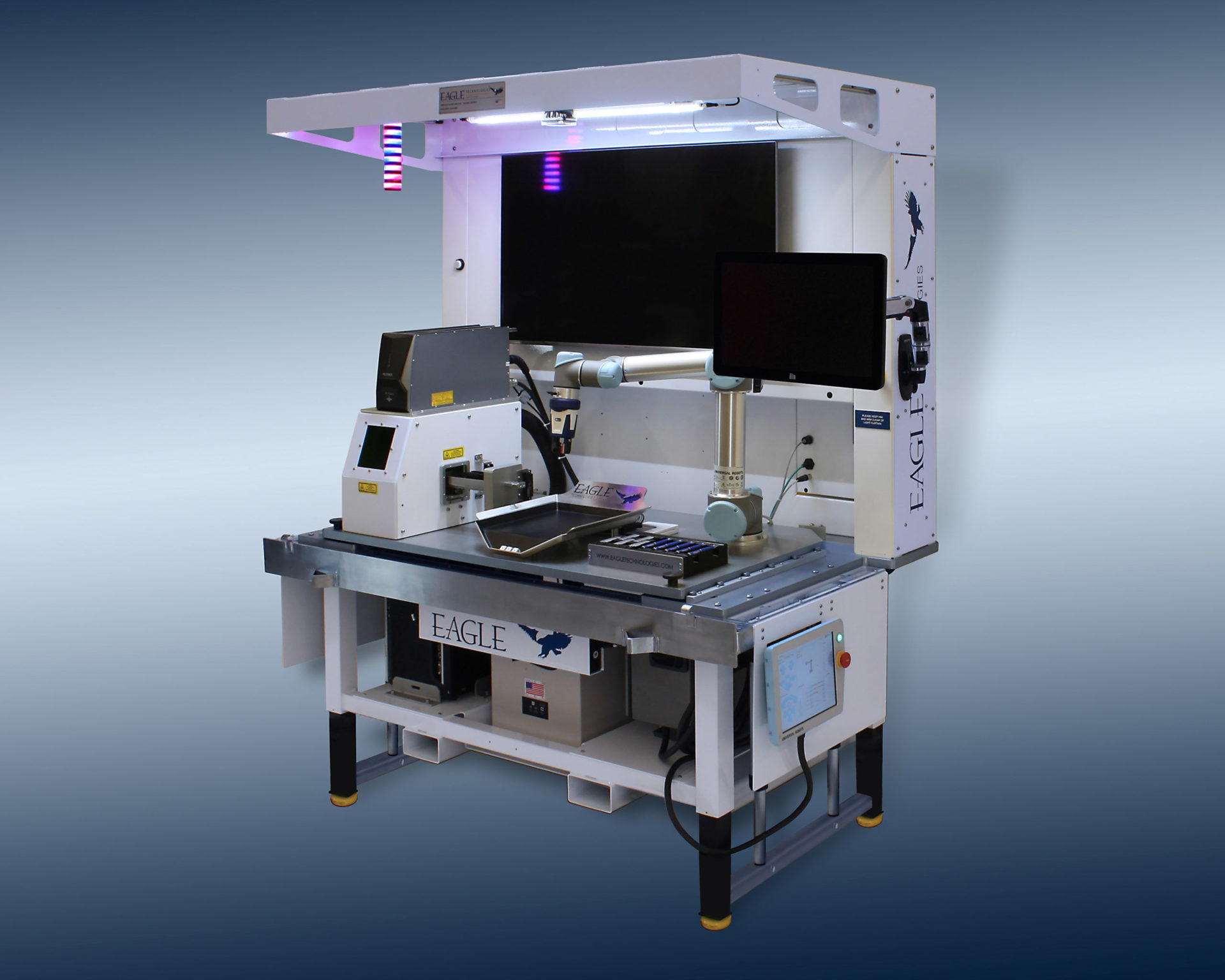

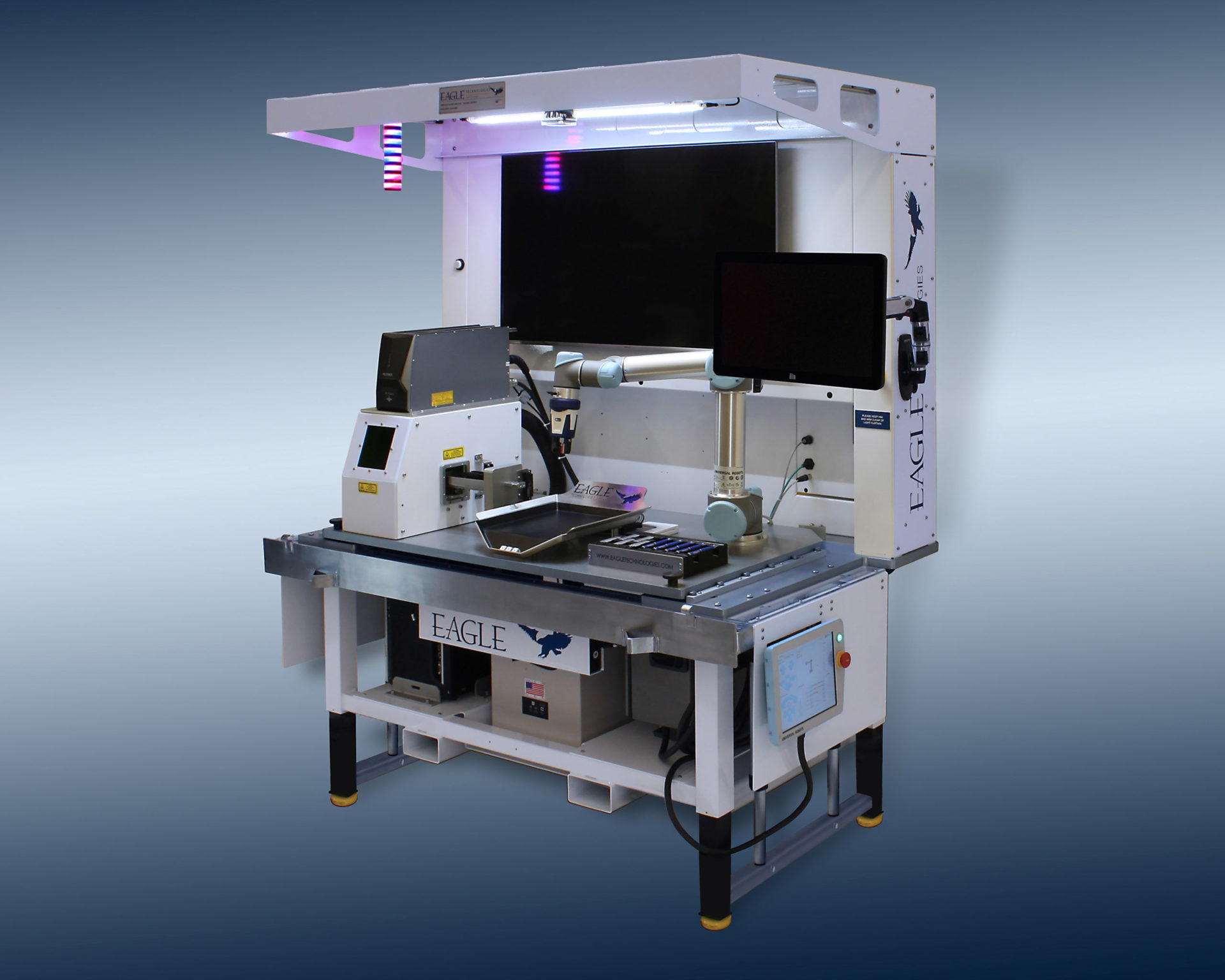

For many small-batch manufacturers, single-purpose automation equipment won’t result in the kind of cost-savings necessary to make the investment worthwhile. These manufacturers may only operate a few days a week, or may produce a low volume of variable product. What they need isn’t an assembly that can churn out thousands of identical components a day, but a flexible system that can easily be changed over from one process to another.

This is exactly what our Universal Base provides. Built to house high-cost hardware with interchangeable tooling plates, it is an affordable solution that places automated assembly within reach for even the smallest manufacturer.

BRINGING FACTORY AUTOMATION TO SMALL MANUFACTURERS

Factory automation has typically required large amounts of capital to invest in large, single-purpose machines designed to produce thousands of components a week.

Our universal base houses the most expensive hardware components, while our interchangeable tooling plates can be custom-built for your specific production requirements.

Challenge

- Full custom automation is too expensive

- Production doesn’t run five days a week

- Has several automated tooling needs

Solutions

- High-cost hardware built into base

- Program-specific custom tooling plates

- Easy to position and dock

- Universal, ergonomic, and ambidextrous

Results

- Affordable manufacturing automation for small production runs

- Reduced overhead costs and low capital expenditure

- Expandable functionality with new tooling plates

COMFORTABLE, USER-FRIENDLY CONTROLS

Our universal base has been ergonomically designed to include electric height adjustment, ambidextrous controls, touch screen operation, an operator fan for comfort, and LED lighting. The HMI is on a swivel arm for easy positioning, and is height-adjustable independent of the base so you can set it to the most comfortable sight-line.

The universal base is also built to be easily moved and docked. The operator panel includes well-lit controls and a pushbutton panel that can be easily positioned along the base rails. There is additional space along the back panel for accessories, which can be built according to customer specifications.

EASY TO CONNECT AND CONFIGURE

Our tooling plates can be swapped out in less than a minute, making it easy for you to change fixtures throughout the day. The universal base comes equipped with standardized control packages to make setup and configuration quick and efficient.

The PLC control system includes Ethernet-IP connectivity, power outlets, programming ports, serial interfaces, and predesigned options for screw driving, leak testing, and part marking. Valves are prewired and plumbed, ready for configuration to your application. We have even included a courtesy airline to keep your work surface clean.

Universal Base Features Include:

BULKHEAD CONNECTORS

- Pneumatics on the fixture

- Discrete I/O on the fixture

- Serial on the fixture (BCR)

- Analog on the fixture

- Other user requirements

Control Package

- Allen Bradley Standard

- CompactLogix PLC

- Panelviewplus 700 HMI

- Ethernet-IP connectivity

- Serial to E-net gateway

- HMI controls Fan, Lights, Height

- Numatics Valve Manifold with Eight valves

- Rotary Disconnect

- Courtesy Outlet

- Programming Port

- Locking Casters

- Fork Truck Tubes

- Painted to your specification

- Pneumatic lockout

- Filter, Regulator, pressure switch

GET TO KNOW EAGLE TECHNOLOGIES

Questions about assembly?

Contact us and we’ll be happy to help!

Intelligent factory automation systems are not composed piecemeal by updating one production step at a time. Rather, they require an end-to-end design, engineered so that each step flows seamlessly into the next. By engineering a complete assembly from start to finish, manufacturers can eliminate choke points and slow areas throughout their production line.

At Eagle, we bring the best of Industry 4.0 technology to bear on our assembly designs. We use simulation software to model how each automated piece will fit together, and use that data do deliver more accurate project estimates. Our team can then return to those simulations to get a jumpstart on automation programming while our build team creates the actual assembly. This process allows us to deliver higher quality products with a shorter turnaround time.

UNIVERSAL BASE

For many small-batch manufacturers, single-purpose automation equipment won’t result in the kind of cost-savings necessary to make the investment worthwhile. These manufacturers may only operate a few days a week, or may produce a low volume of variable product. What they need isn’t an assembly that can churn out thousands of identical components a day, but a flexible system that can easily be changed over from one process to another.

This is exactly what our Universal Base provides. Built to house high-cost hardware with interchangeable tooling plates, it is an affordable solution that places automated assembly within reach for even the smallest manufacturer.

BRINGING FACTORY AUTOMATION TO SMALL MANUFACTURERS

Factory automation has typically required large amounts of capital to invest in large, single-purpose machines designed to produce thousands of components a week.

Our universal base houses the most expensive hardware components, while our interchangeable tooling plates can be custom-built for your specific production requirements.

Challenge

- Full custom automation is too expensive

- Production doesn’t run five days a week

- Has several automated tooling needs

Solutions

- High-cost hardware built into base

- Program-specific custom tooling plates

- Easy to position and dock

- Universal, ergonomic, and ambidextrous

Results

- Affordable manufacturing automation for small production runs

- Reduced overhead costs and low capital expenditure

- Expandable functionality with new tooling plates

COMFORTABLE, USER-FRIENDLY CONTROLS

Our universal base has been ergonomically designed to include electric height adjustment, ambidextrous controls, touch screen operation, an operator fan for comfort, and LED lighting. The HMI is on a swivel arm for easy positioning, and is height-adjustable independent of the base so you can set it to the most comfortable sight-line.

The universal base is also built to be easily moved and docked. The operator panel includes well-lit controls and a pushbutton panel that can be easily positioned along the base rails. There is additional space along the back panel for accessories, which can be built according to customer specifications.

EASY TO CONNECT AND CONFIGURE

Our tooling plates can be swapped out in less than a minute, making it easy for you to change fixtures throughout the day. The universal base comes equipped with standardized control packages to make setup and configuration quick and efficient.

The PLC control system includes Ethernet-IP connectivity, power outlets, programming ports, serial interfaces, and predesigned options for screw driving, leak testing, and part marking. Valves are prewired and plumbed, ready for configuration to your application. We have even included a courtesy airline to keep your work surface clean.

Universal Base Features Include:

BULKHEAD CONNECTORS

- Pneumatics on the fixture

- Discrete I/O on the fixture

- Serial on the fixture (BCR)

- Analog on the fixture

- Other user requirements

Control Package

- Allen Bradley Standard

- CompactLogix PLC

- Panelviewplus 700 HMI

- Ethernet-IP connectivity

- Serial to E-net gateway

- HMI controls Fan, Lights, Height

- Numatics Valve Manifold with Eight valves

- Rotary Disconnect

- Courtesy Outlet

- Programming Port

- Locking Casters

- Fork Truck Tubes

- Painted to your specification

- Pneumatic lockout

- Filter, Regulator, pressure switch