MOVE YOUR COMPONENTS FROM A TO B

Several considerations must be factored into account during the creation of a factory automation assembly, including the number of stations, the fragility of the components, and the space within the factory. We base our automation solutions off your factory floor plan and product requirements to create systems that can safely and efficiently move product through your space.

CONVEYOR SYSTEMS

Conveyors are some of the oldest and most reliable methods for moving parts through a manufacturing production line. Our conveyors systems come in a range of sizes with advantages and disadvantages based on application. We can help you find the right solution.

DIAL MACHINES

Although a hard automation, dial and carousel machines provide a robust and long-lasting solution for quickly moving components from one location to another. We can retool these machines for more flexible applications, or repurpose them for a new application within your factory.

MOBILE ROBOTS

Mobile robots are a special territory of robotics solutions. They have an advantage in many factory situations in that they can freely navigate a factory floor without prior programming, avoiding people and objects as they go. As a new but highly adaptable technology, they are expanding robotics applications within the factory automation industry.

Most robots in an automated factory setting are fixed in place, with a known reach and weight tolerance to allow them to handle parts within their range. Mobile robots serve a different purpose. Whereas transporting components and pieces from one area of the factory floor to another has traditionally required some form of conveyor technology, mobile robots offer a belt-free mode of transport with a range that covers the entire factory floor.

Our mobile robots can safely navigate office and factory environments without colliding with people or other objects in their path. We can custom tool their components to accept various on-loading and offloading procedures, and program automations that will enable them to interface with other material handling machines.

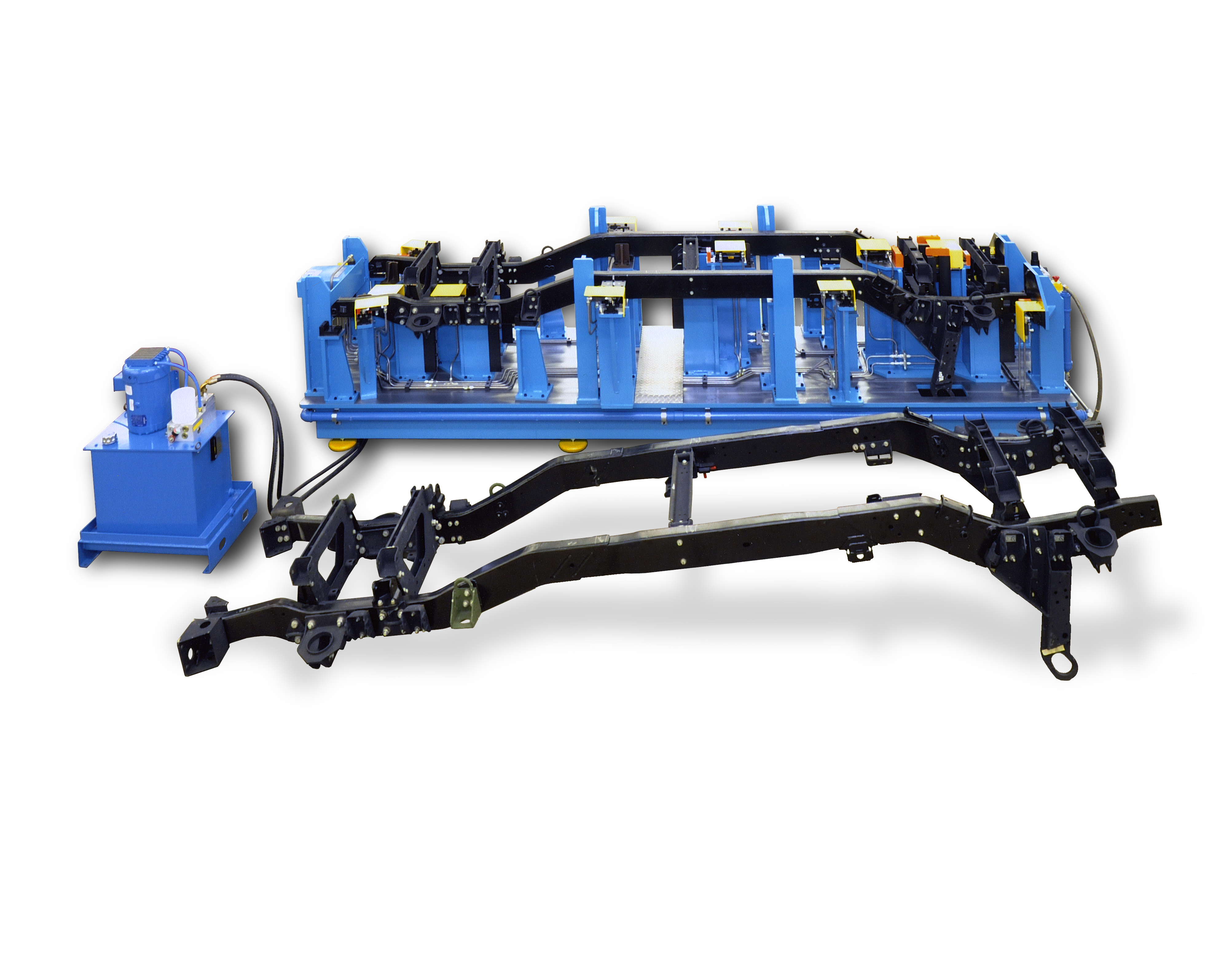

HITCH FEED & WALKING BEAM

Whereas conveyor belt and even mobile robot solutions require loading parts onto a pallet or some other surface for transportation, which must then be returned to the start of the production line, hitch feeds and walking beams can move product through a manufacturing process without the need of an additional loading platform.

FIXTURE DESIGN

We sometimes encounter manufacturing needs that are not suited for automation, such as very low volume processes. For these, we use our expertise create safe and ergonomic fixtures that can be used manually or automatically to produce the same time-quality results as our automatic assemblies.

MANUAL WORKSTATIONS

Operator workstations remain a central component of many factory automations, whether their role is to oversee production or move the process forward. We design high-quality ergonomic workstations for operators that are designed to optimize comfort, safety, and productivity.