How 3D Printing Is Transforming Customized Medicine

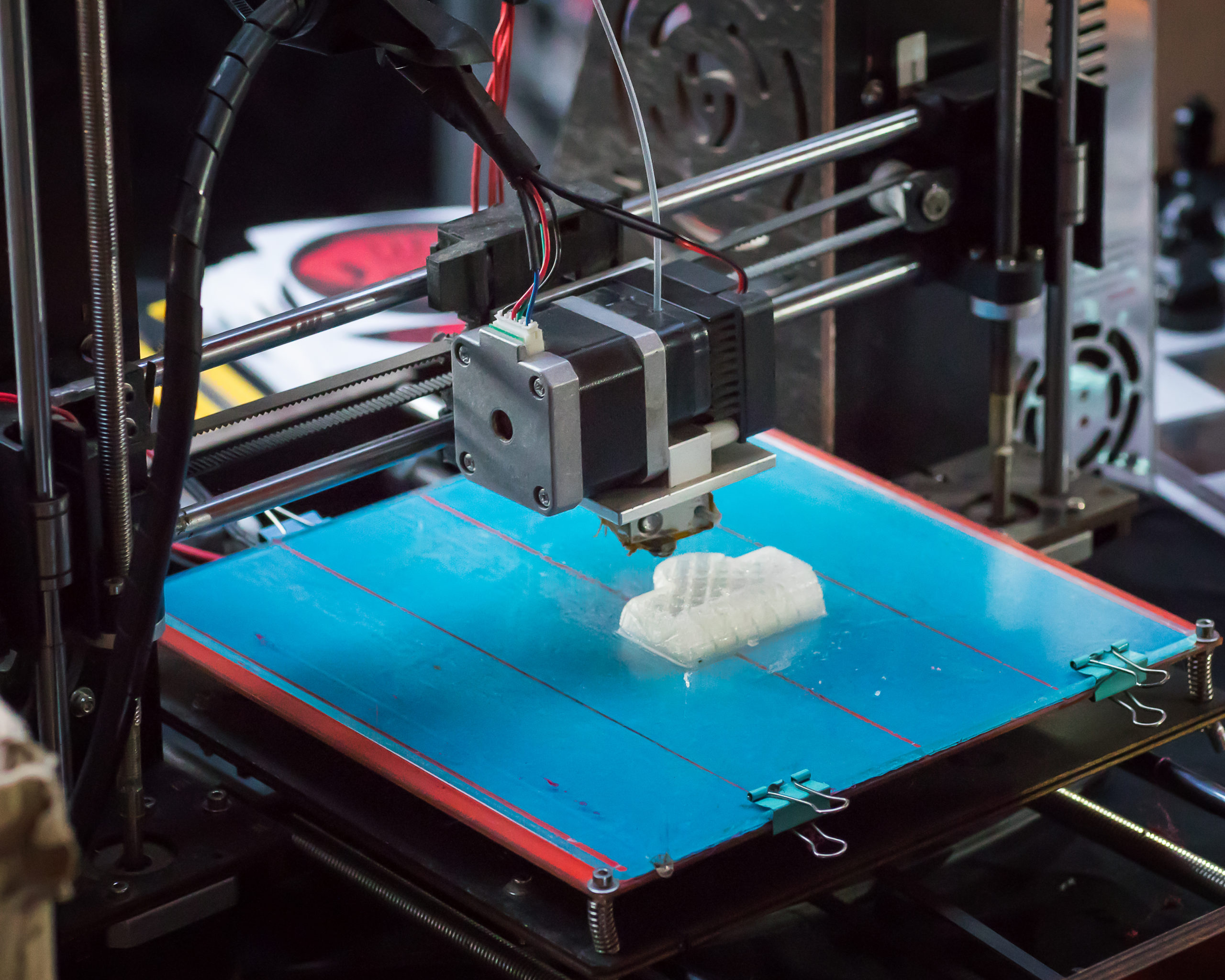

Additive manufacturing is filling an unmet niche in the healthcare industry. Traditional manufacturing transformed global markets by providing cost-effective ways to produce goods en masse. A hallmark of mass production has long been conformity. Manufacturers set a quality standard, and then develop their processes to ensure a uniform output that meets...