Additive manufacturing is achieving its potential with the help of existing automation technologies.

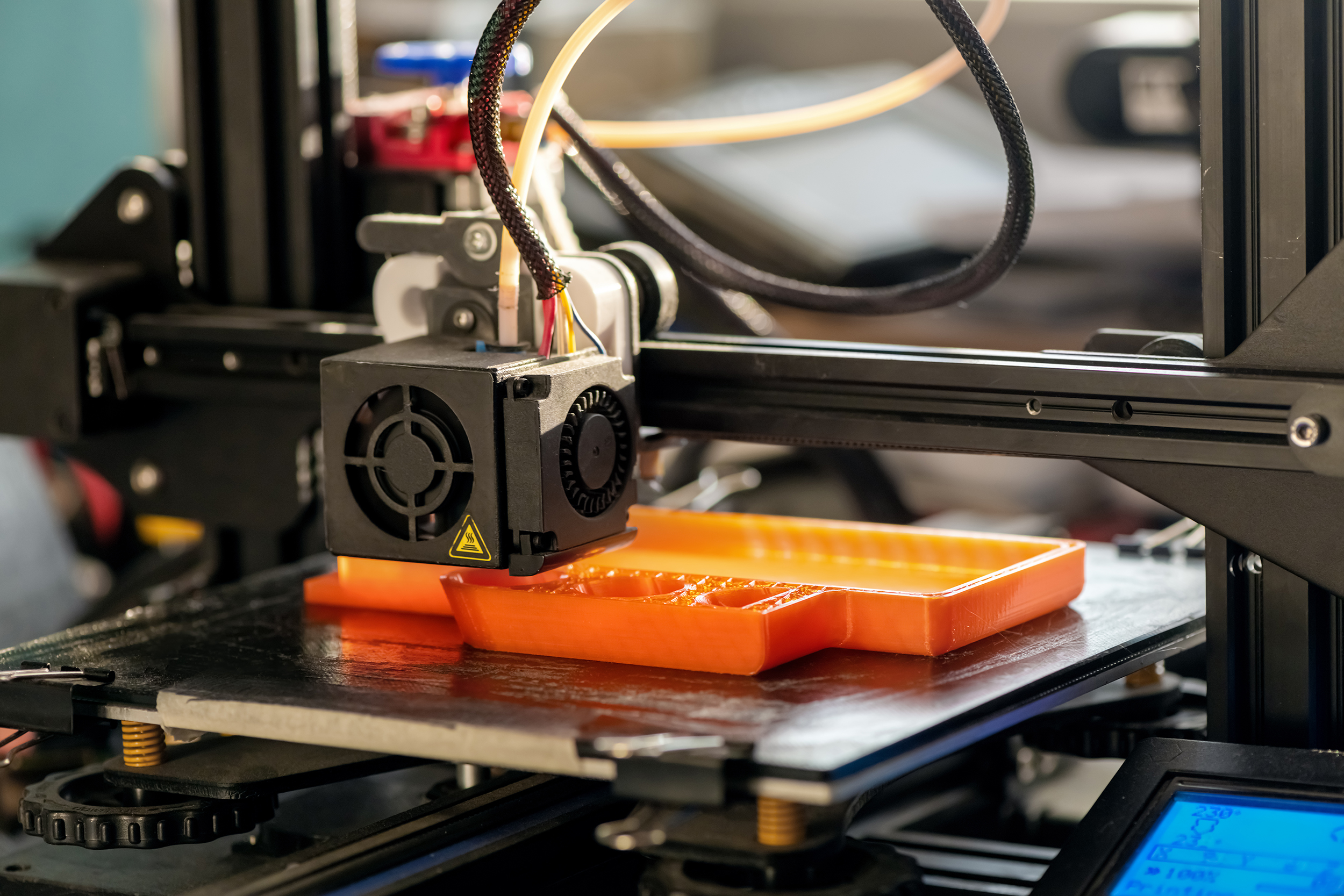

Additive manufacturing, more commonly known as 3D printing, has the potential to be a massively disruptive technology. The ability to use a single machine to produce virtually any design seems, at first glance, fundamentally incompatible with traditional large-scale manufacturing methods, which rely on subtractive machining processes and robotic production lines.

But 3D printing is still in the process of becoming a viable technology at an industrial scale. High-touch operation and post-processing needs have slowed its growth—hurdles that factory automation technology is helping to overcome. Disruptions in the global supply chain are making flexible, fast, local manufacturing more desirable than ever, and automation is helping 3D printing scale up to meet the increased demand.

With help from robotic material handling, advanced sensors, and smart manufacturing, 3D printing is poised to grow. Here’s how automation is transforming additive manufacturing.

1. Increased throughput

For a long time, 3D printing was a high-touch process. Jobs needed to be started manually, printers needed additional supplies, and finished products needed to be harvested and transported for post-processing. Today, automation is impacting every part of this process to streamline production and eliminate stoppages.

Triggering jobs automatically lets production run without the need for a worker’s intervention. Automation software can re-trigger jobs that fail, or reassign a job to another printer in the event of an equipment issue. To free up the print chamber for the next job, robotic arms harvest printed products, and can either store them for collection by a worker, or automatically transport them to post-processing. And when printers need additional print media, automated systems can dispense it.

These resupply and harvesting jobs are repetitive and precise—tasks that robots can handle quickly and consistently. Combined with automated job management, printers can run continuously with minimal downtime. This increased efficiency on individual tasks, together with the possibility of lights-out manufacturing, creates the opportunity for major productivity gains.

2. Scalability

A key problem with industrial-scale 3D printing is that every hurdle one printer presents is multiplied with additional printers. The logistics of resupplying, troubleshooting, and harvesting increase when they need to be coordinated across a production line’s worth of devices. These are the moments when automation shines.

A software system with visibility into factory data can make sure that print jobs are assigned as needed, and in the most efficient way possible, to avoid bottlenecks behind lengthy or complex jobs. Automation systems can orchestrate resupplying printers or harvesting printed products, and if a job—or a printer—fails, dynamically reassign the job to a different device. As jobs vary across printers, software can redirect the appropriate print media for robotic handlers to refill.

Prioritizing and reprioritizing, reassigning resources, and resetting equipment are time-consuming and logistically taxing. Automated systems have a high-level view of the entire printing process, and can coordinate its various parts to optimize production.

3. Quality control

Existing automated manufacturing systems already contain high-tech quality control that works for 3D printed products too. Advanced vision systems are highly accurate at interpreting visual data, and don’t run the risk of fatigue. Integrating vision technology into the production line allows automated inspection of printed products for visible defects, speeding up the post-processing and reducing errors.

Data analytics has also become a critical part of quality control and improvement in Industry 4.0, and 3D printing equipment is no different. Smart manufacturing technology is already capable of collecting sensor data and using it to improve product quality and workflow efficiency. The same data can capture lags or errors in 3D printing processes, and help identify opportunities to streamline production.

4. New methods

Leaders in 3D printing are aware that, for the most part, they’re not arriving in the industrial manufacturing space with a blank slate. Existing factory configurations and workflows represent a massive investment in large-scale production, and replacing or redesigning factory lines would scrap a great deal of effort and capital.

That’s why integrating 3D printing with existing automation technology has become a valuable option. Leveraging existing commonly-used robotic arms as part of the printing process, printers can rotate the print bed or printed object itself to generate products more efficiently. This capability is especially useful in printing with advanced composites, reducing the need for support structures while printing and making it easier to properly align reinforcement fibers within the material.

Existing industrial manufacturing technologies are also elevating 3D printing capabilities at the level of the factory floor. Automated transporters can physically move print chambers to different production locations to more efficiently complete portions of large projects, placing them closer to necessary supplies and post-processing. Centralized automation software can intelligently assign jobs and direct the necessary materials to production stations, minimizing touch points. These processes support more modular factory equipment, which simplifies repairs and upgrades and allows for flexible production. It also paves the way for future increases in automation.

Factory automation will build the future of additive manufacturing.

The vast potential of 3D printing is not news. The process’ customizability and its capacity to leverage new materials are unparalleled. The biggest hurdle in taking full advantage of these tools has been the logistics involved in scaling up to industrial production levels. But automation has changed the game for 3D printing, making existing processes faster, more efficient, and higher quality. Not only that; existing automation technology has even been combined with 3D printing to create wholly innovative production methods.

With customers looking to diversify supply chains in the face of global challenges, US-based manufacturing is facing increasing demand. Contact Eagle Technologies if you’re interested in discussing how automation can help you scale up or transform your 3D printing operations. We can help you craft automation solutions tailored to your production needs.

![]() Connect With Eagle Technologies LinkedIn

Connect With Eagle Technologies LinkedIn

Eagle Technologies, headquarters in Bridgman, MI

Eagle builds the machines that automate manufacturing. From high-tech robotics to advanced product testing capabilities, Eagle offers end-to-end manufacturing solutions for every industry.