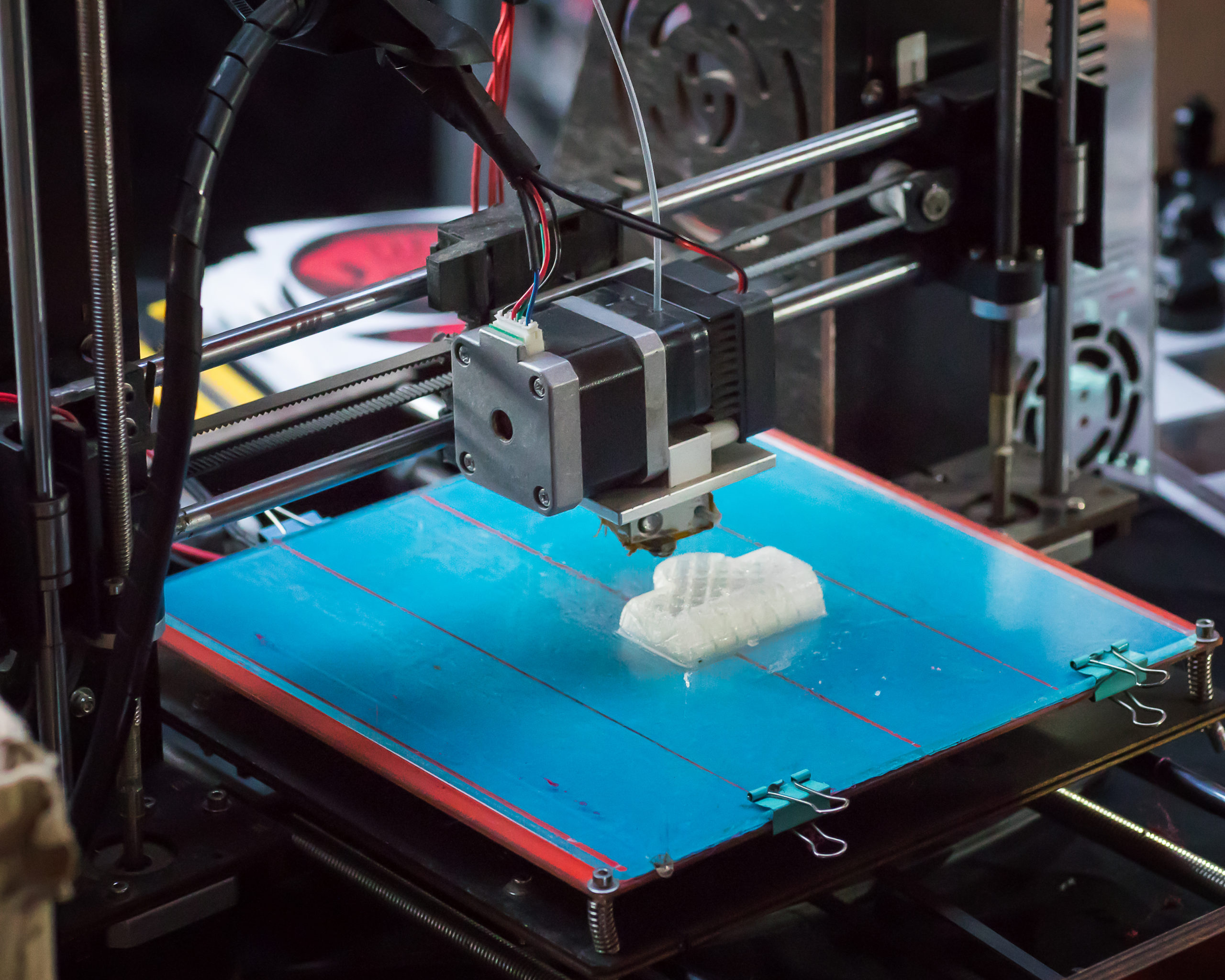

Eagle Technologies uses 3D printing in our development process to improve our assembly design. Using production specifications from the manufacturer, we can print models in various materials and use them to test concepts or suggest design modifications that might improve the final assembly. The ability to edit a design document and quickly print an alternative component helps our engineers build better automation equipment for our clients.

As a result of the time and cost savings made possible by 3D printing, we are able to deliver estimates and quotes that are more accurate and more competitive than other manufacturers in our field. These benefits ultimately roll over to our customers, who further benefit from the more collaborative relationship made possible by our rigorous prototyping methods.

Lets Talk.

Contact us and we’ll be happy to help!