5 Ways to Error-Proof Manufacturing Processes

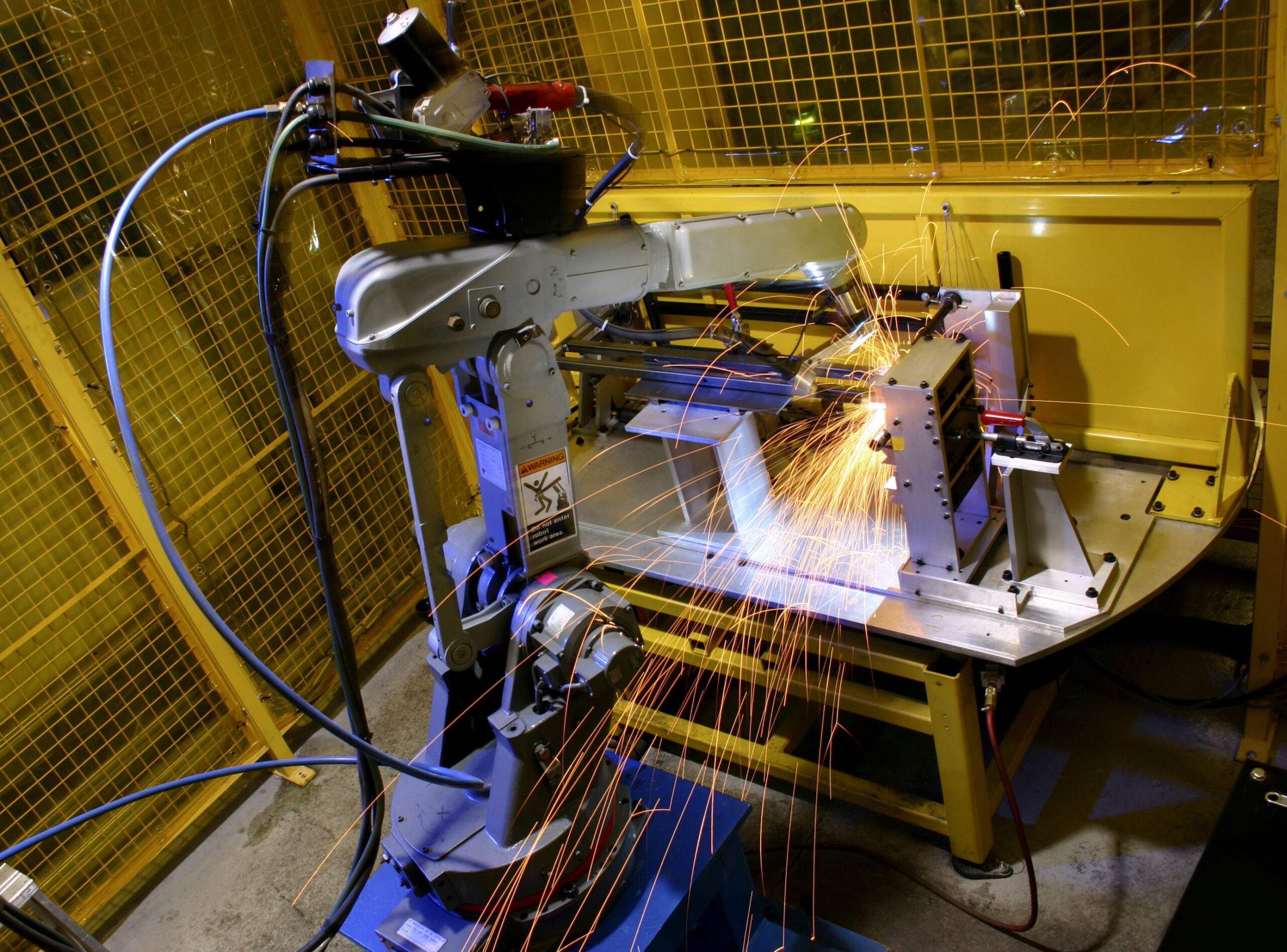

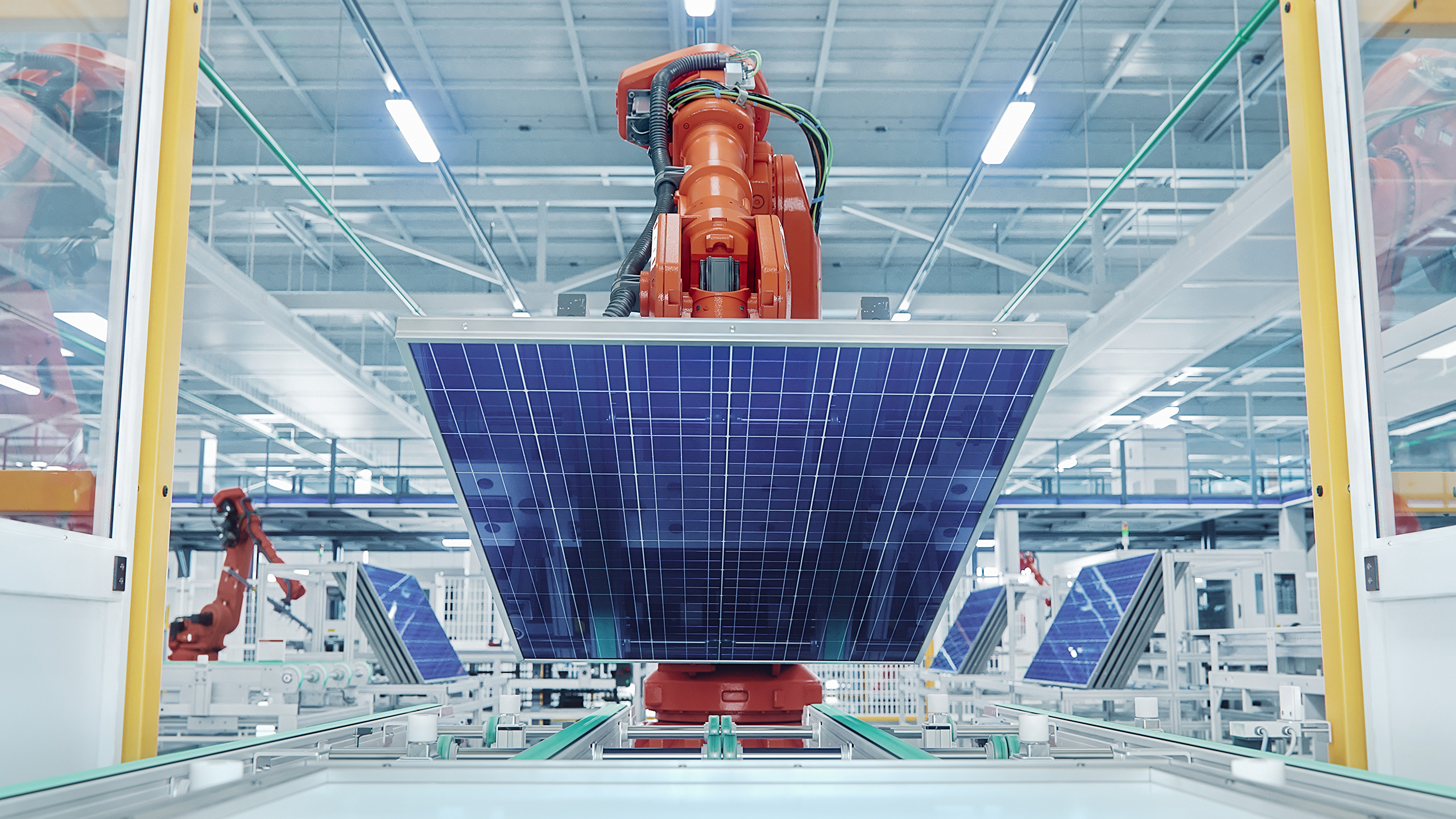

Manufacturing automation can be designed to prevent, detect, and mitigate errors before they reach consumers. Errors can enter the manufacturing stream from numerous sources. From flaws in the base material, to equipment that malfunctions, to problems with the design itself. But many of the most common—and preventable—errors can come from human...