ELECTRIC VEHICLE, HYBRID VEHICLE, EV BATTERY CAPABILITIES

EXPERIENCE

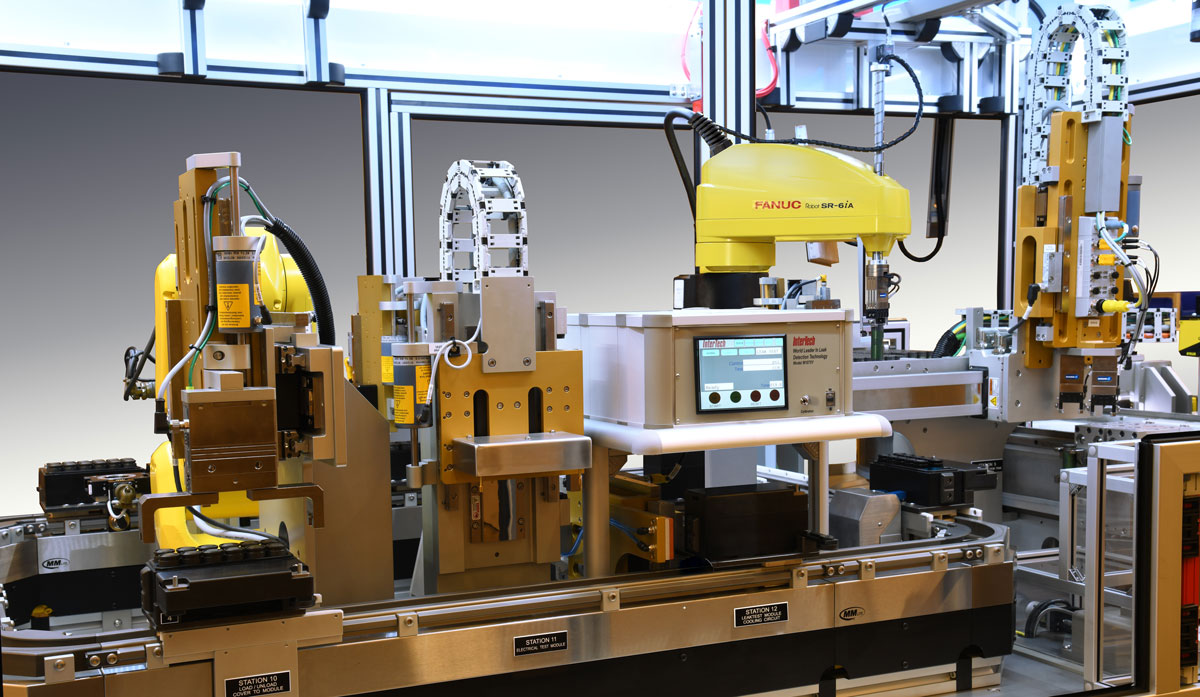

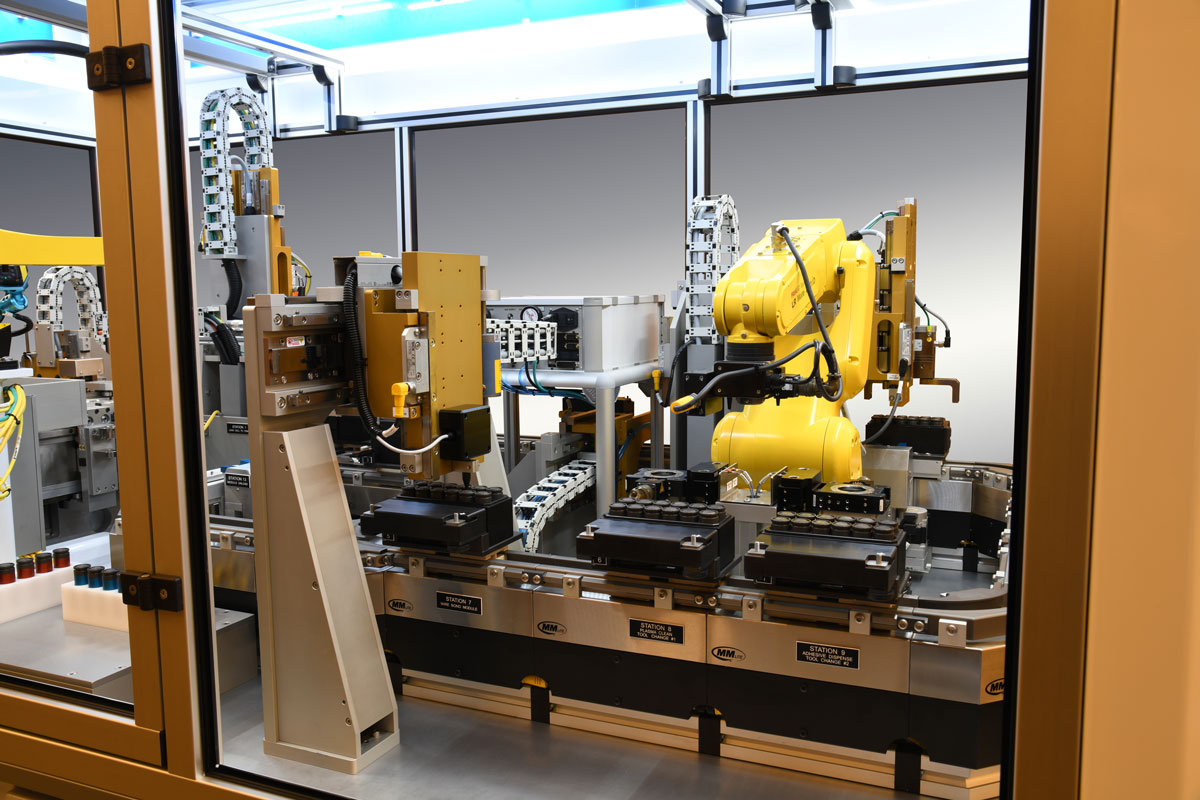

$200M engineered, manufactured production equipment delivered and installed in the last 10 years.

$20M in electric and hybrid vehicle lab/prototype and Advanced Test equipment delivered.

$1M invested by Eagle in advanced technologies at the San Jose Electric Vehicle Innovation Center.

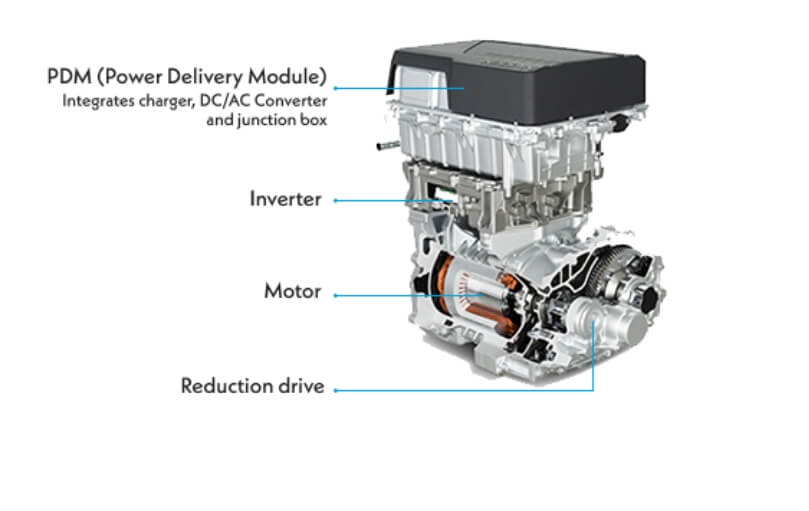

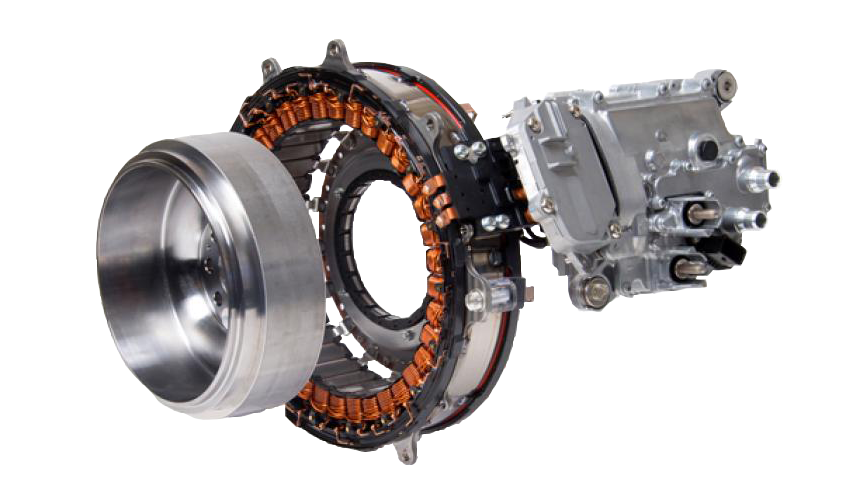

MOTOR EXPERTISE

- Motor winding, lead straightening, lead twisting

- End of line testing

- 3D wire shaping

- Wire Brushing

- Lead routing

- De-reeling

- Straightening

- Stripping

- Cut to Length

- Forming

- Lamination Insertion

- Final Twisting

- Welding

- Inspection

- Dielectric Testing

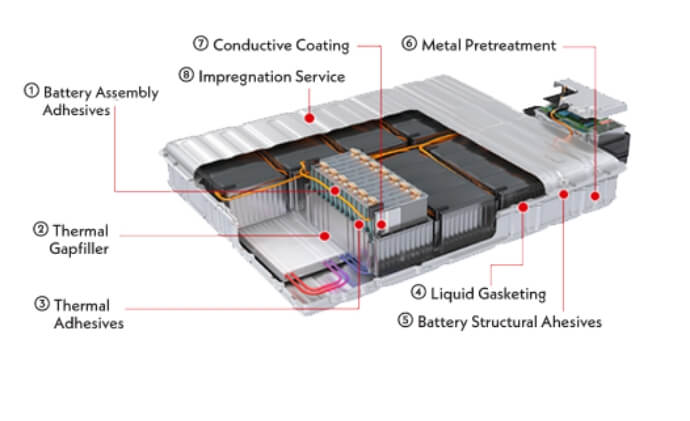

BATTERY EXPERTISE

- Cell test and load stand-alone machines or in process

- Automatic battery positioning for wire bond processes

- Terminal voltage sense harness

- Pulse test (stationary or on-the-fly)

- Review, rework and interface with MES

- Bar-code tracking of products and RFID

- Module close, test and leak test

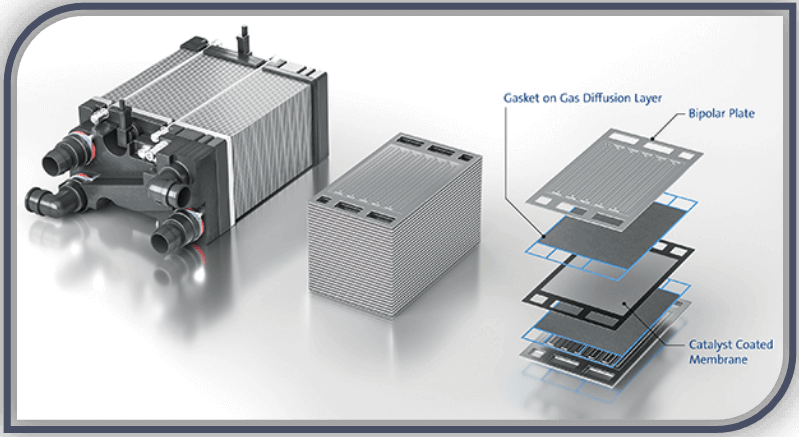

- Plate Fabrication

- Cell Assembly, Encapsulation & Test

- Module Assembly

- Weld, Leak & Functional Test

- Pack Assembly

- 3D Vision Inspection

- Dispensing

- Weighing

- Sonic and Hot Plate Welding

TEST EXPERTISE

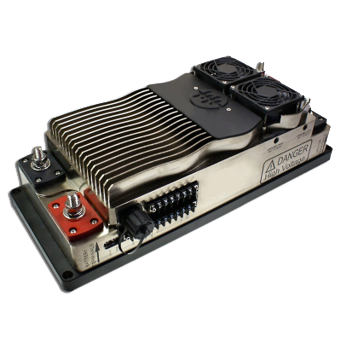

- Advanced test of motors using high-speed dynamometers

- Inverter validation and final test for powertrain module

- Leak test including mass spec

- Electrical

- Stators/motors/rotors – wiring, short detection, TIR and spin up to 20,000 RPM

- Drive units

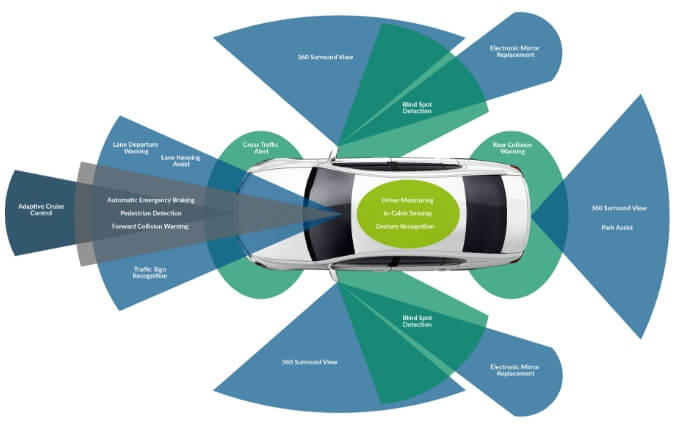

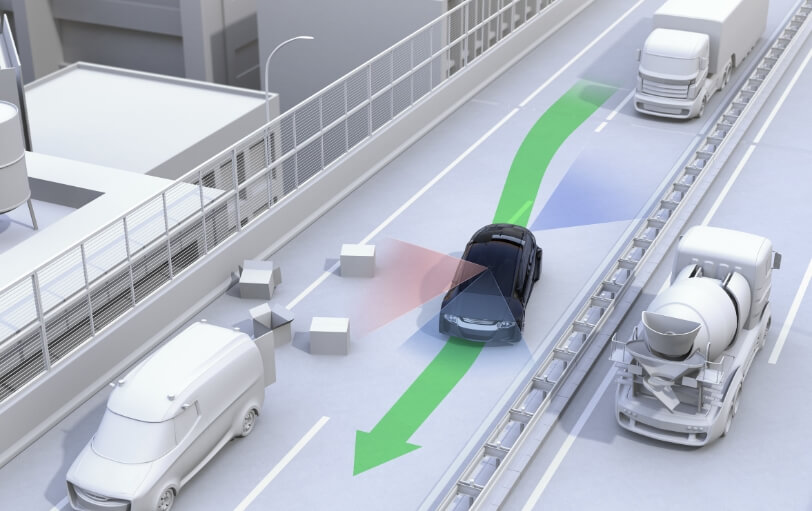

- Autonomous

- Mirror accessories

- Fuel cell

- ADAS (advanced drive assistance systems)

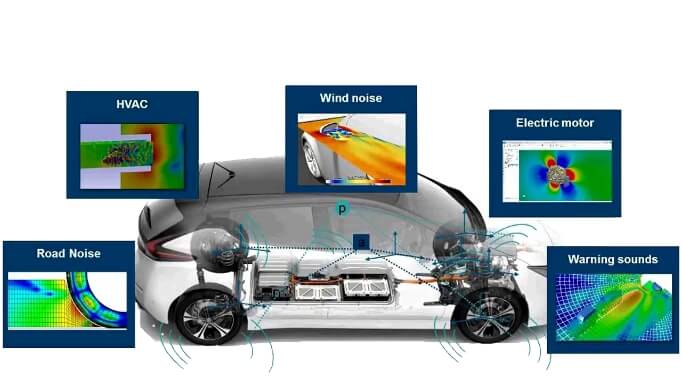

Complete NVH test stands (end of line and stand alone)

Optimizing automotive manufacturing processes is nothing new for machine builder Eagle Technologies. Headquartered in Bridgman, Michigan, the company has served the automotive industry for over 50 years and has delivered turnkey assembly and test systems for nearly every vehicle component.

As electric vehicles have advanced, Eagle Technologies has been on the cutting edge of new technology with prototype development and production systems for both batteries and motors.

WHAT IS THE ELECTRIC VEHICLE INNOVATION CENTER?

An immersive experience that helps customers quickly and cost-effectively develop their vision of Factory Automation, Connected Enterprise and Digital Factory in EV and battery production

Our Opportunity

A high-tech facility where manufacturers interested in learning more about the electric battery and drive-train manufacturing processes can see first-hand technologies used in EV production.