AUTOMATED PRODUCTION OF ELECTRIC VEHICLES AND TEST EQUIPMENT

Every part of an electric vehicle, from the powertrain to the autonomous systems, requires rigorous testing and validation to ensure proper functioning and prevent the need for a costly recall.

Our investment in the EV industry leaves us uniquely positioned to run verification tests on our machines that demonstrate the reliability and repeatability of our methods. Our facilities include both an advanced testing center in the Detroit Metro area and an EV Innovation Center in San Jose, California featuring our Electric Battery Assembly Machine.

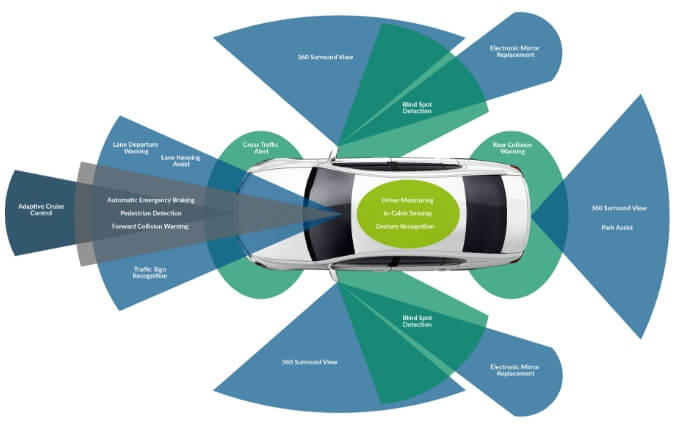

ADVANCED DRIVER ASSIST SYSTEMS

While fully autonomous vehicles are still rare, vehicles with advanced driver assist systems are the new standard for the latest range of models. These features include parking assistance, collision warnings, and object tracking.

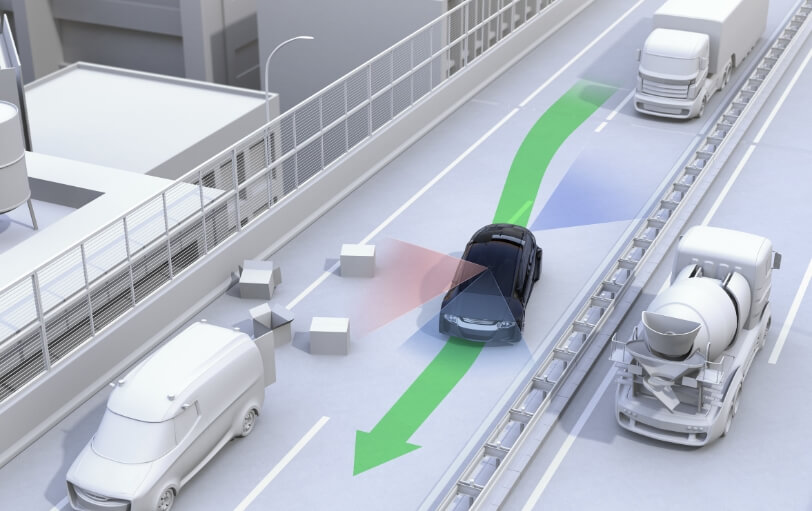

AUTONOMOUS

The sensor technology powering autonomous vehicles demands highly accurate input data that can monitor and respond in real-time to rapidly changing driving conditions. These systems must be tested extensively to demonstrate that they can safely replace human control of a vehicle.

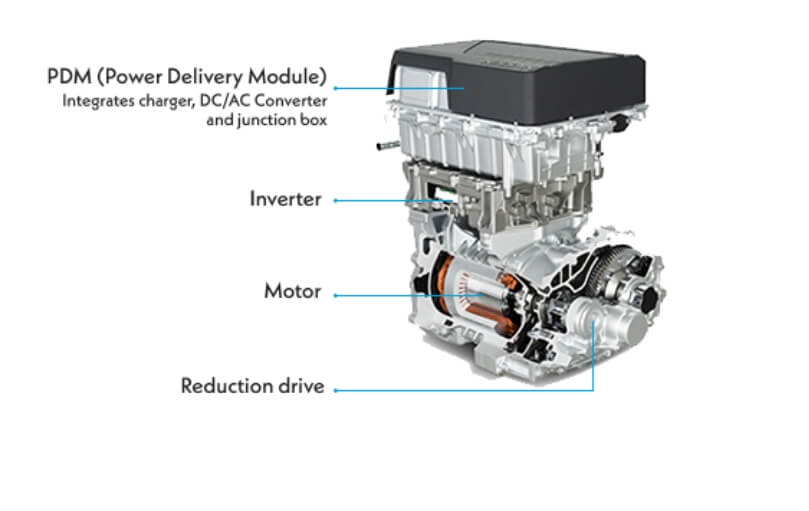

DRIVE UNITS

In an electric vehicle, the drive unit is what translates driver input from the accelerator pedal into speed adjustments in the motor inverter. Our testing verifies that these signals are transmitted appropriately.

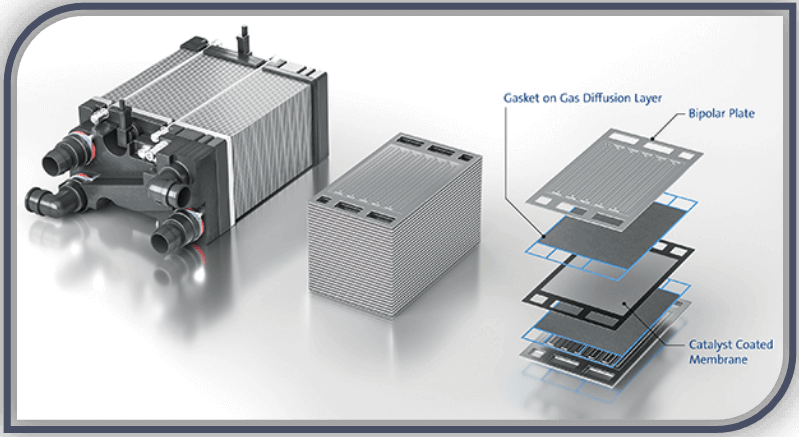

FUEL CELLS

Fuel cells are an alternative to batteries for producing energy for electric vehicles. A zero-emissions technology, they rely on the chemical reaction of hydrogen and oxygen to create a charge for the electric engine.

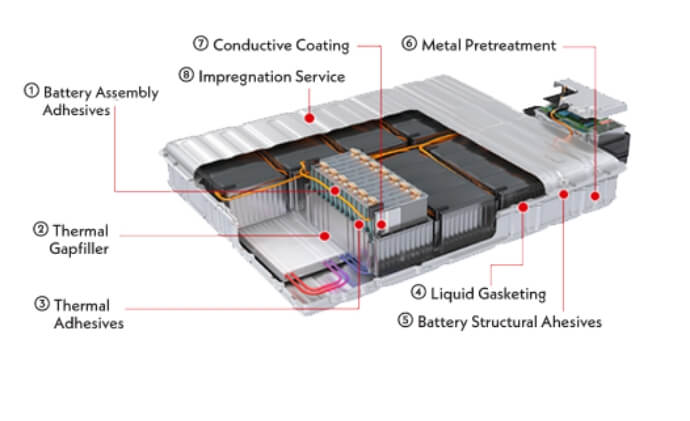

BATTERIES companies compete to engineer more powerful batteries for electric vehicles, our testing verifies that the new systems meet the design standards. We offer specialized test systems for battery assemblies for EV powertrains that monitor heat transfer, charge efficiency, and energy transfer to the inverter.

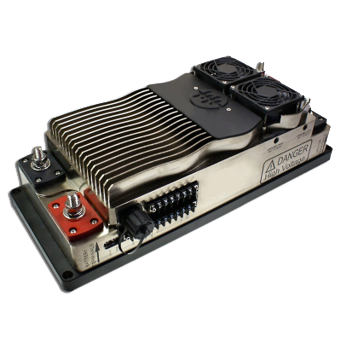

INVERTERS

As the component used both to convert DC to AC energy, and to control speed and torque, the inverter plays an essential role in the EV powertrain. Our testing validates the individual components, and ensures they function properly within the final assembled powertrain module.

We truly view our relationship with Eagle as a partnership. The team has been excellent at proactively looking for potential improvement to our existing design. We are growing so rapidly that we must rely on outside help to accomplish our expansion goals on time as wells as address the known issues in our process. Eagle has been key on helping us accomplish both.

Battery Technology Customer

MIRROR ACC.

The next generation of auto technology integrates additional sensors and monitoring systems to relay traffic information to the driver or the autonomous controller. Our test systems check the quality of this data to ascertain its reliability.

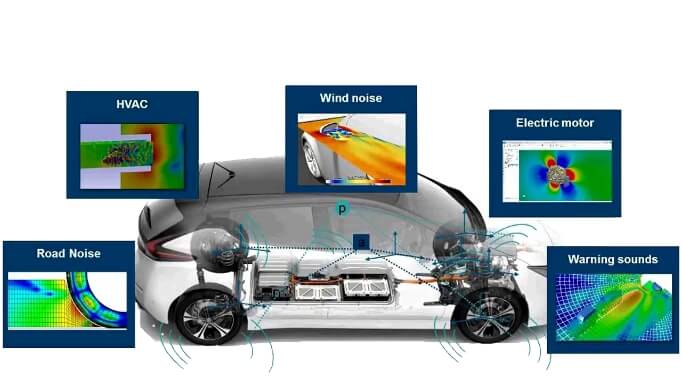

NVH

Electric vehicles are quieter than their combustion-fueled counterparts, and so naturally lower levels of noise, vibration, and harshness are expected. In some cases, this has raised new problems related to pedestrian safety.

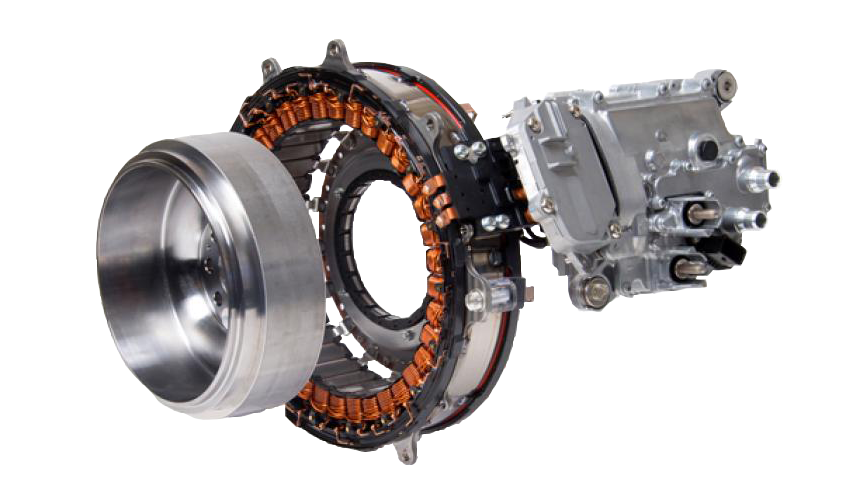

STATORS/MOTORS/ROTORS

The EV motor is one of the most finely-tuned components in an electric vehicle. With rotors running at up to 20,000 RPM, and stators that require complex wiring to function, each part needs to be properly validated before it can be integrated into the final assembly.

GET TO KNOW EAGLE TECHNOLOGIES

Lets Talk.

Contact us and we’ll be happy to help!