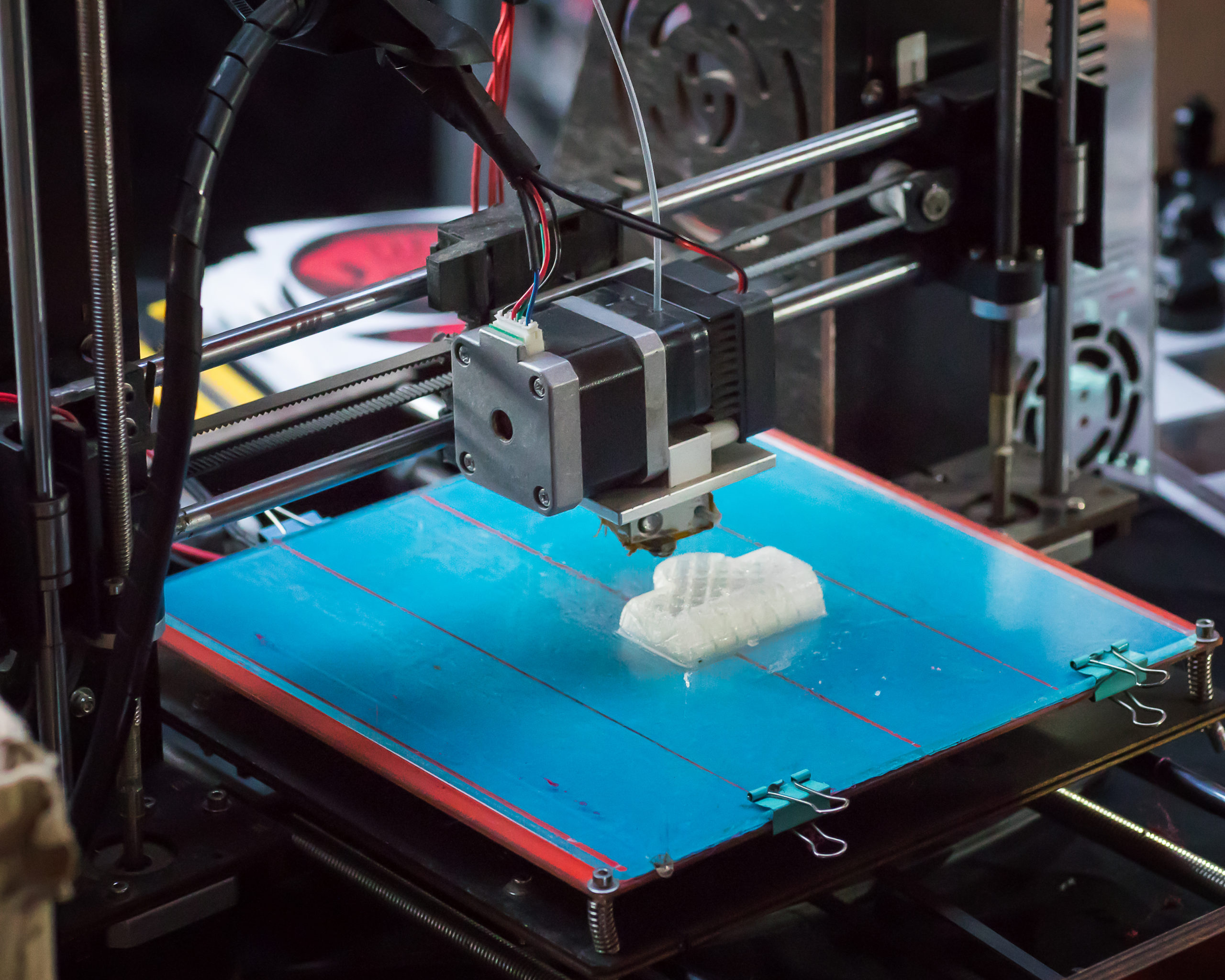

Additive manufacturing is filling an unmet niche in the healthcare industry.

Traditional manufacturing transformed global markets by providing cost-effective ways to produce goods en masse. A hallmark of mass production has long been conformity. Manufacturers set a quality standard, and then develop their processes to ensure a uniform output that meets that standard. As a result, in numerous ways that are often overlooked, consumers have adapted and adjusted their habits to fit into a mass-produced world.

In many industries, this emphasis on uniformity is no bad thing. However, if there’s one sector where this approach does not work, it’s in healthcare. No two bodies are the same, and quality of care depends on treatments that conform to individual needs rather than an industry standard. Unfortunately, delivering truly custom care has often been difficult, both logistically and in terms of cost-effectiveness. The good news is that new manufacturing technologies and methods are rewriting the game, making custom care treatments more accessible for a wide range of patients.

When it comes to individual care, no technology is having a greater impact than 3D printers. From enabling new experiments in medical research and development to bringing point-of-care additive manufacturing directly into hospitals, the full potential for this technology is still being explored. Here are the top ways it is currently being used to improve patient care.

1. Anatomical models.

Doctors are beginning to use anatomical models when working with patients in need of specific medical interventions to discuss care with that patient and consult with colleagues about the best treatment approach. This can be especially important for extremely rare procedures, where doctors are dealing with unfamiliar circumstances or testing a novel approach.

2. Wearable devices.

While it may not be the first industry to spring to mind when you think about prosthetics, dentistry has been leading the charge for many years now. 3D printing is increasingly being used to produce dentures and dental restorations. In the realm of wearable devices, 3D printing has taken over the production of clear aligners and retainers and is also more commonly being used to produce hearing aids and other personal devices.

3. Prosthetics.

3D printing has impacted personal prosthetics by improving functionality, fit and comfort, and overall patient outcomes. 3D printing can result in lighter-weight prosthetics, which cause less strain and pressure on surrounding joints and tissues. Apart from being designed to provide a more exact fit, they can also be adjusted to provide more cushioning based on a patient’s height and weight.

New foams have also been printed for use in device sockets to provide more dynamic cushioning. Current research into the future of 3D printing and prosthetics is focused on smart devices that may be able to respond to changes in heat, moisture, or pressure by changing shape, changing temperature, or delivering medication.

4. Implants.

3D printing for external medical uses is one thing, but internal uses are another. On the one hand, they face higher regulatory standards, but on the other, they are an area where custom implants have a lot more to offer. For instance, 3D-printed implants made using more porous materials not only lead to better long-term stability, but even reduce the time a patient spends in surgery by up to 25%.

Bioprinting—using 3D printing to create living tissue—represents the current cutting edge of this field. Although current research is focusing on printing bone and skin tissue, it may be possible to one day print whole custom organs with reduced risk of host rejection.

5. Personalized medications.

Already, high-mix, low-volume (HMLV) manufacturing is improving the field of medical compounding to reduce the cost of custom medication. But 3D-printed medications could take this field a step further. Medications for children could be printed with more precise dosages that take into account the age and weight of the child. Drugs can also be printed with more carefully formulated release rates based on whether a patient needs immediate relief or sustained relief. For elderly patients, medications can be printed with designs to help them remember which day of the week to take their pills, while, medications printed in braille could protect visually impaired patients from inadvertently taking the wrong medicine.

6. Custom tools.

Imagine a doctor in an operating room, needing to make an incision at a difficult angle. What if they could create a custom brace to help hold the patient in place so that they can have the best access? A 3D printer could be used to create tools that are custom fitted to the doctor’s hand, allowing for better maneuverability and reducing strain and muscle fatigue.

- Prototyping.

Finally, on the research and development side of things, developing new tools and devices can be greatly expedited using the rapid prototyping provided by 3D printing. For instance, 3D printing allows researchers to print several versions of a device or tool using different materials simultaneously in a matter of hours. This speeds the iterative process, helping new solutions reach the market faster.

The future of medicine is not one-size-fits-all.

Modern healthcare treatments are capable of taking greater account of an individual’s biology, physiology, and genetics. Broad adoption of these technologies is currently held back by regulatory difficulties, which in turn make it less likely that these treatments will be reimbursed by insurance companies. However, since 2018 the pace has begun to change, and given the transformative potential of these treatments, it couldn’t come a moment too soon.

At Eagle Technologies, we routinely use 3D printing for rapid prototyping in our production methods and have applied our advanced manufacturing experience in the pharmaceutical and medical device industry. If you are interested in hearing how our expertise could help your business, contact us today, and we will put you in touch with one of our service representatives.

![]() Connect With Eagle Technologies LinkedIn

Connect With Eagle Technologies LinkedIn

Eagle Technologies, headquarters in Bridgman, MI

Eagle builds the machines that automate manufacturing. From high-tech robotics to advanced product testing capabilities, Eagle offers end-to-end manufacturing solutions for every industry.