Aircraft production and maintenance are complex processes. Here’s how automated vision systems can help streamline them.

Aerospace manufacturing presents unique challenges as a low-volume, large-scale industry with tight regulations. Both the production chain and the day-to-day upkeep of aircraft involve rigorous checks across many moving parts. Under fluctuating real-world conditions, inspection and quality checking are an area where efficiency gains could make a real difference to the aerospace industry—but have historically presented a hurdle for automation.

Given the tightly regulated nature of aerospace development, the bulk of inspections—particularly of existing equipment pre-flight—are completed manually, by human technicians. Manual inspections are expensive in terms of time, labor costs, and logistics. But the growth of machine learning, and the increasing ease of bringing big data into the field, represent potential wins for speed and efficiency. Automated vision systems can, with proper training, complete inspections faster, more consistently, and at a lower cost. Here are five key points in the aircraft design and maintenance lifecycle where automated vision systems can make a difference.

1. Identification and staging

Staging equipment and resources properly before assembly can compound efficiency gains in the actual assembly process. To that end, vision systems that can identify and track parts, tools, and resources like cobots or automated transport units can play a key role in preparing for production.

Straightforward optical vision systems are ideal for scanning barcodes or reading labels on packaging. They allow conveyor and picker systems to route parts and materials to the appropriate locations. More intelligent systems, on the other hand, can examine the parts themselves, identify them, and potentially accept or reject them as suitable before passing them along for staging. Three-dimensional tracking systems can pinpoint the location of objects within a set space, like a warehouse or factory floor, and let manufacturers direct resource movements from a high-level view.

2. Quality checks

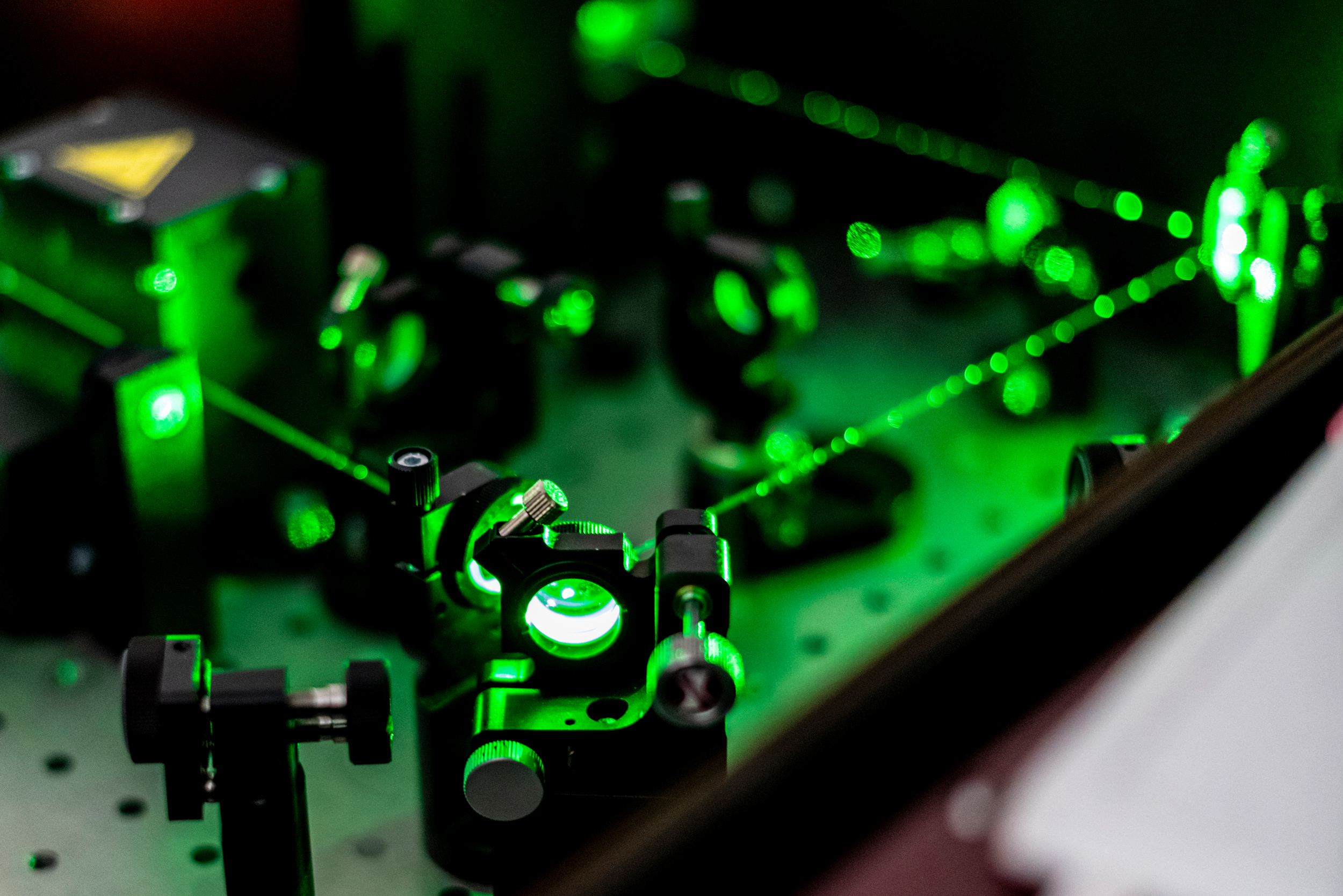

Automated vision systems already have a track record of success in quality-control roles. In a stable, controlled environment, a vision system can measure components against pre-defined requirements and assess for predictable flaws—but these systems often encounter challenges when dealing with lighting changes, motion, reflectivity, and other real-world conditions.

However, AI systems are overcoming some of these hurdles. These systems extrapolate many of their own heuristics from bulk data sets, making them more flexible in their ability to identify and categorize faults. Automated vision systems can also incorporate advanced detection capabilities, like UV inspection or resistance testing, directly into their processes—something workers can’t access without additional tools.

3. Assembly verification

Automated vision systems scale up more efficiently than a manual workforce, which is a real advantage in aerospace, where qualified workers are already in short supply. Inspections that would require additional workers at an exponential cost can be conducted relatively easily by existing vision systems. Large-scale systems at the level of a warehouse or production facility consist of laser or infrared scanning, as well as 3D sensor and visual-marker tracking.

These laser scanning and tracking systems can inspect partially- or fully-assembled products, both to make sure that they meet pre-defined tolerances, and to ensure that all parts are present and accounted for. They can also integrate with data collection to document the production history of each component, enhancing traceability and enabling future reporting. This data collection contributes to both a detailed three-dimensional model of assembled aircraft, and a robust record of the manufacturing and assembly processes, which can be used for later analysis.

4. Maintenance and damage detection

Hardware inspections are a significant bottleneck in airline operations, due to time and labor requirements. Inspections are critical for equipment safety and quality, and are understandably tightly regulated; they are also one of the least automated jobs, with roughly 80% of inspection tasks still being handled manually.

Advanced vision systems trained on real-world examples of materials stress and damage can speed this process dramatically, by bringing the industry’s body of technical experience to bear on the shop floor. Cracks, dents, and deformations can be gauged against a massive body of data to quickly determine whether they fall within safe tolerances. The same principle can be applied to regular maintenance on aircraft in service, alerting technicians when a part may be wearing out or is due for replacement.

5. Digital twinning and advanced design

The digital transformation is in full swing across the manufacturing industry, and advanced vision systems are one more high-quality input for existing enterprise resource planning analytics. A key component of Industry 4.0 is the digital twin: a data duplicate of an entity that can give manufacturers the transparency of real-time updates and the flexibility of low-risk innovation.

With the information that cutting-edge vision systems can capture, digital twins of aerospace products can be more detailed than ever. Digital design requires a minimal investment of resources, and a digital twin makes it much easier to iterate on an as-built blueprint. Designers can test new configurations, model stresses and wear, and even simulate assembly processes to find optimal workflows.

The advances in automated vision systems are supporting efficiency leaps in the aerospace industry.

Aerospace manufacturing’s large scale and exacting regulations have historically represented an efficiency hurdle. Manual inspections and real-time, large-scale resource tracking require significant labor and time. With automated vision systems supported by robust machine intelligence, the effect of these bottlenecks is beginning to shrink.

The experts at Eagle Technologies are ready to work with you on adding vision systems to your assembly and quality-control workflows. If you’re interested in more information about how advanced vision systems can help you optimize your aerospace business, contact us today.

![]() Connect With Eagle Technologies LinkedIn

Connect With Eagle Technologies LinkedIn

Eagle Technologies, headquarters in Bridgman, MI

Eagle builds the machines that automate manufacturing. From high-tech robotics to advanced product testing capabilities, Eagle offers end-to-end manufacturing solutions for every industry.