The Internet of Things (IoT) has been discussed more and more often recently as internet technologies have improved and data collection has become more actionable. What does this mean for the automated factory?

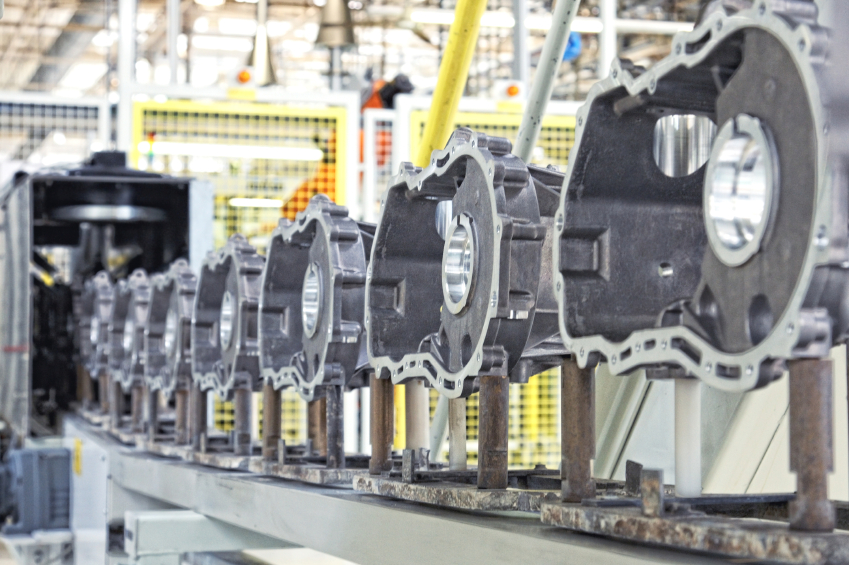

As more useful data is able to be collected and internet and cloud technologies become more widespread and secure, the automated factory is able to know in real-time what is happening on the factory floor. The automated factory is also able to be more flexible and efficient, making changes to the manufacturing process, the products being manufactured, and know when maintenance is necessary in order to keep downtime to a minimum.

So far, businesses have made progress in applying the Industrial Internet of Things to reduce operational expenses, boost productivity or improve worker safety. Drones, for example, are being used to monitor remote pipelines, and intelligent drilling equipment can improve productivity in mines.

…As with the Internet, however, there is more growth, innovation and value that can be derived with smart IIoT applications.

[T]raditional manufacturers and industrial leaders now have the opportunity to embrace the IIoT. …as long as they think unconventionally, they have a chance to generate new growth with the Industrial Internet of Things.

The IoT also makes reshoring more feasible. By creating smarter, safer, more flexible, and more efficient factories, bringing manufacturing back to the U.S. is easier than ever to undertake. Along with the benefits to the IoT technologies, by bringing manufacturing closer to consumers, changes in consumer preferences and demands can be easily and flexibly acted on.

Read more about the future of the connected factory: Reimagining Business With the Industrial Internet of Things by Paul Daugherty at Re/Code