Preparing to automate a plant is an exciting prospect. Automation can easily make the processes and

production run more efficiently than before. The prospect of new technology is also exciting in itself.

Despite the thrill, plant managers shouldn’t leap too quickly into automating their work space. Doing so

can have consequences that can eat away at profits and cut down on production. These are not the only reasons why you should think carefully before you automate.

Avoiding Unnecessary Costs

Proper consideration of the processes, products and plant size can lead to an efficiently outfitted and

highly productive company. A hasty decision about the automative tools needed in the plant can lead

to unnecessary purchases. Those purchases come with a price tag, meaning unnecessary costs. There is also the cost of retrofitting and “remodeling” to consider, as this is often needed to fix the problems of an inaccurately fitting system. To avoid unnecessary costs, companies must take the process analysis steps of the automation process seriously, using honest and accurate data from the plant floor.

One Size Doesn’t Fit All

Another mistake that companies make is seeing an automation setup is one plant environment and

believing that setup is best for more than one company. Automation is a tailored process that requires

specific analysis of each individual product, machine and process. The result is a system that made for

one company and is often not suitable for another.

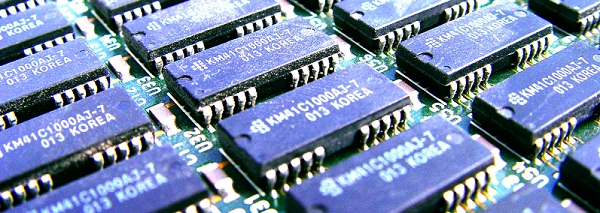

The Newest Technology May Not Be the Best

Again, the tools of automation are tailored for each company. Equipment and devices are utilized as

needed, with the best tool for the job taking precedent. This means using the technology that best suits the design and the plant’s needs. Oftentimes, the best technology isn’t the newest. Automating the plant is not a place where the newest and brightest technology matters, unless that technology is is the best for the process at hand.

Automating a plant is the best decision that many can make. However, the process should not be taken

lightly. Utilize the process analysis information so that the best automative system for the plant can be

chosen.

Eagle Technologies Group is an industry leader in the design and implementation of factory automation systems worldwide.