To save costs and make up for a shortage of skilled labor, construction companies are turning to prefabricated components. How can factory automation help?

The construction industry around the world is currently facing significant opportunities and significant challenges. On the one hand, growing demand for affordable housing, large-scale infrastructure projects, and improving living conditions in developing countries are fueling a construction boom.

On the other hand, labor shortages and conflicting governmental policies, as well as the ongoing Covid-19 pandemic, have delayed or halted many of these projects. And while some of the obstacles facing the construction industry may be short lived, others will continue to be limiting factors unless a solution can be found.

Fortunately, automation may provide just the solution the construction industry is looking for. Here are a few of the top benefits.

5 benefits of automation in the construction industry.

- Narrowing the skills gap. Construction industries around the world are suffering from a lack of skilled workers. Automation can fill that gap, increasing productivity for construction crews.

- Improving working conditions for laborers. Many of the jobs automation would replace are undesirable for human workers due to their danger or high risk of injury. Automation can take over these jobs, and also help create a safer, cleaner working environment.

- Attracting new workers. One of the underlying challenges of the skills gap crisis in construction is that the labor is viewed as dirty, dangerous, and underpaying. However, advanced technology can make these jobs more attractive to workers, especially those who are willing to gain expertise in construction automation.

- Reducing waste on construction sites. Waste is a huge problem in many construction projects, which has consequences for project budgets as well as for the environment. Automated systems are typically more efficient, leading to less waste.

- Expediting construction timelines. Delays are commonplace in the construction industry, causing many projects to run over time and over budget. Automation can help construction companies stay on schedule.

- Reducing budget costs. Delays, waste, injuries, and labor shortages all show themselves in more expensive budgets. But automation can reduce these costs, while also improving efficiency, leading to more affordable projects. Affordable projects in turn leads to more work, as decision makers in the public and private sector alike can invest in a broader range of construction and infrastructure projects.

4 applications for automation in the construction industry.

None of this is to say that construction in the automation industry will be without challenges. While automation has traditionally been deployed in controlled environments where processes can be optimized for a high level of efficiency and consistency, each construction sites is unique, with a degree of variability.

However, construction automation can overcome these challenges in two ways: by creating controlled environments in which to automate construction projects, and by using adaptive technology that can be responsive to an uneven terrain or a dynamic work environment. Here’s what some of these solutions look like.

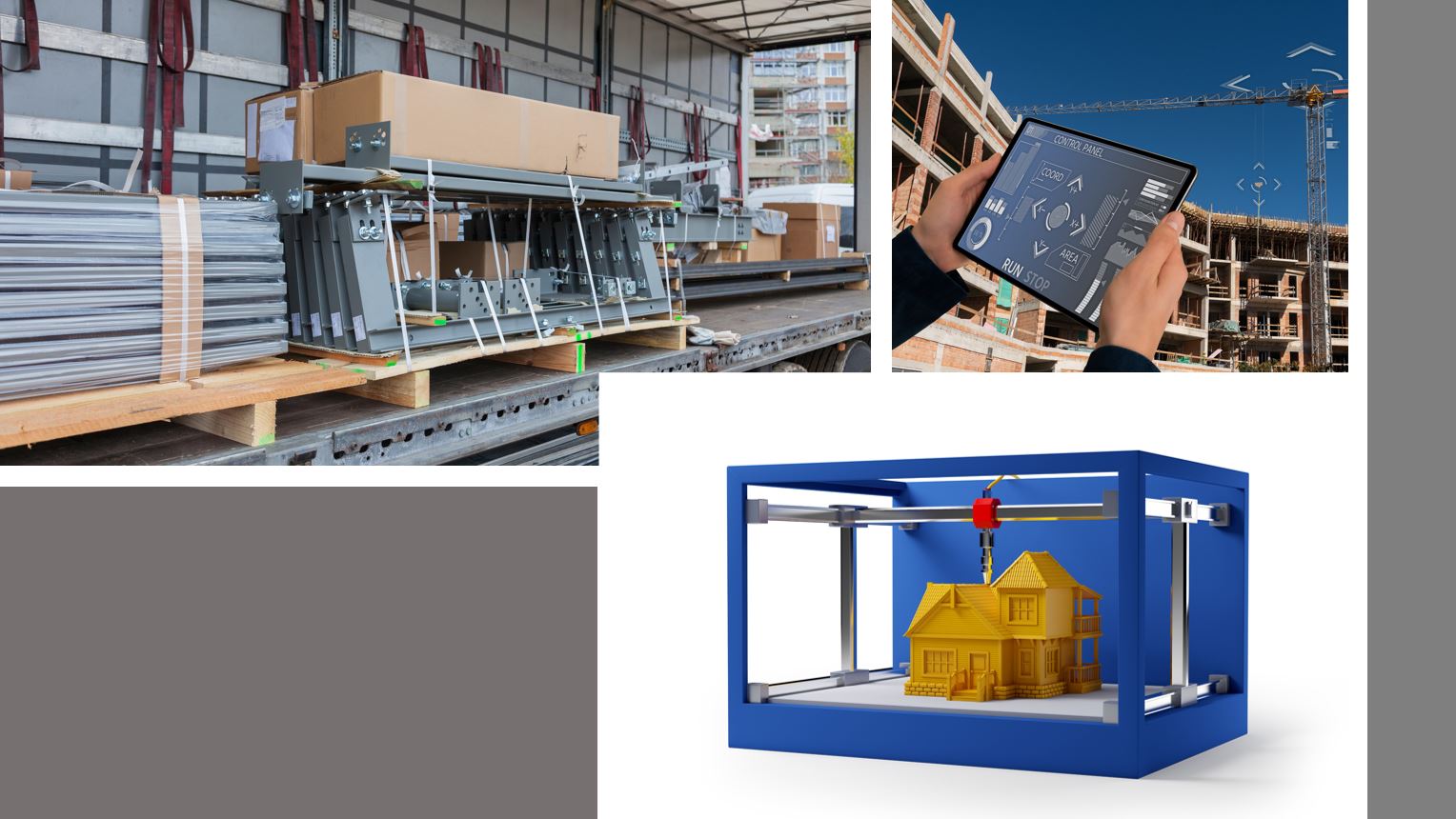

1. Prefabricated components.

Prefabricated components have long been a part of the construction industry, but advances in technology are continuing to expand the kinds of components that can be manufactured. Today, construction companies around the world are turning to automation to build units that can be shipped to a construction site and set into place like building blocks.

A large factory can not only assemble large components in a controlled environment, it can also manufacture new materials to be used in construction projects. Some companies are creating designs using engineered wood, which can be cut to specified shapes within a factory, and then shipped. Similarly, large scale 3-D printers are opening up possibilities for architects and engineers to innovate in the design of construction projects.

2. 3-D printed concrete structures.

Speaking of 3-D printing, more companies are experimenting with ways to bring additive manufacturing directly to the job site. Companies in the Netherlands and China have used this technology to print foot bridges on location, and other companies are experimenting with using 3-D printing to build homes.

While printed concrete is a new material that is still being studied, the speed at which these projects can be deployed is truly impressive. It only takes a small team to transport and set up the printer, after which the 3-D printer takes over. Projects can be completed in a matter of hours, with far less expense, and with reductions in waste as well.

3. Autonomous equipment.

Currently, many construction jobs are completed with large machines that are controlled and operated by humans. But with visioning technology becoming more advanced, there’s not much separating human-controlled equipment from autonomous equipment. Imagine autonomous construction equipment which could be left overnight to prepare a construction site, or a legion of robots that could be deployed to level a freshly-poured concrete floor. These projects would require oversight, but would reduce the amount of hard labor involved.

4. Advanced safety systems on job sites.

Finally, autonomous equipment has safety benefits as well. A human operator is prone to making mistakes, especially if they’re tired, and job sites are open, noisy environments that can make it hard for operators to see and hear everything around them. Autonomous equipment—human-operated equipment with assistive technology—doesn’t have these problems. An autonomous bulldozer could have sensors monitoring its environment at all times, and could shut down any time it detected unexpected movement from a human—or even an animal.

Automation has a bright future in the construction industry.

Automation offers too many advantages for the construction industry not to move forward. And these advantages will have cascading benefits for everyone. Construction workers will have safer work environments, governments will be able to invest more broadly in infrastructure, private citizens will have more affordable housing options, and construction companies will be able to complete more projects in budget and on a more reliable timeline.

While this technology is still developing, we at Eagle are excited to see where it will go. Our own specialization in automated factory solutions makes us well suited to help businesses design and develop prefabricated construction projects in a controlled environment. We are also highly experienced in working with autonomous equipment and in developing safety systems to protect workers in environments that use robots and automated equipment. Contact us if you’d like to speak with us further about our capabilities.

![]() Connect With Eagle Technologies LinkedIn

Connect With Eagle Technologies LinkedIn

Eagle Technologies, headquarters in Bridgman, MI

Eagle builds the machines that automate manufacturing. From high-tech robotics to advanced product testing capabilities, Eagle offers end-to-end manufacturing solutions for every industry.