The last two years have been tough for chip manufacturers.

The pandemic has thrown global supply chain vulnerabilities into sharp relief, and in few places has it been more visible than in the effect of chip shortages on product availability and delivery timelines. These challenges have prompted the high-tech industry to reevaluate its supply networks, prioritizing diverse and local sources of critical components. The United States government recognizes the importance of the domestic semiconductor industry as well, having recently passed legislation designed to support American fabrication plants.

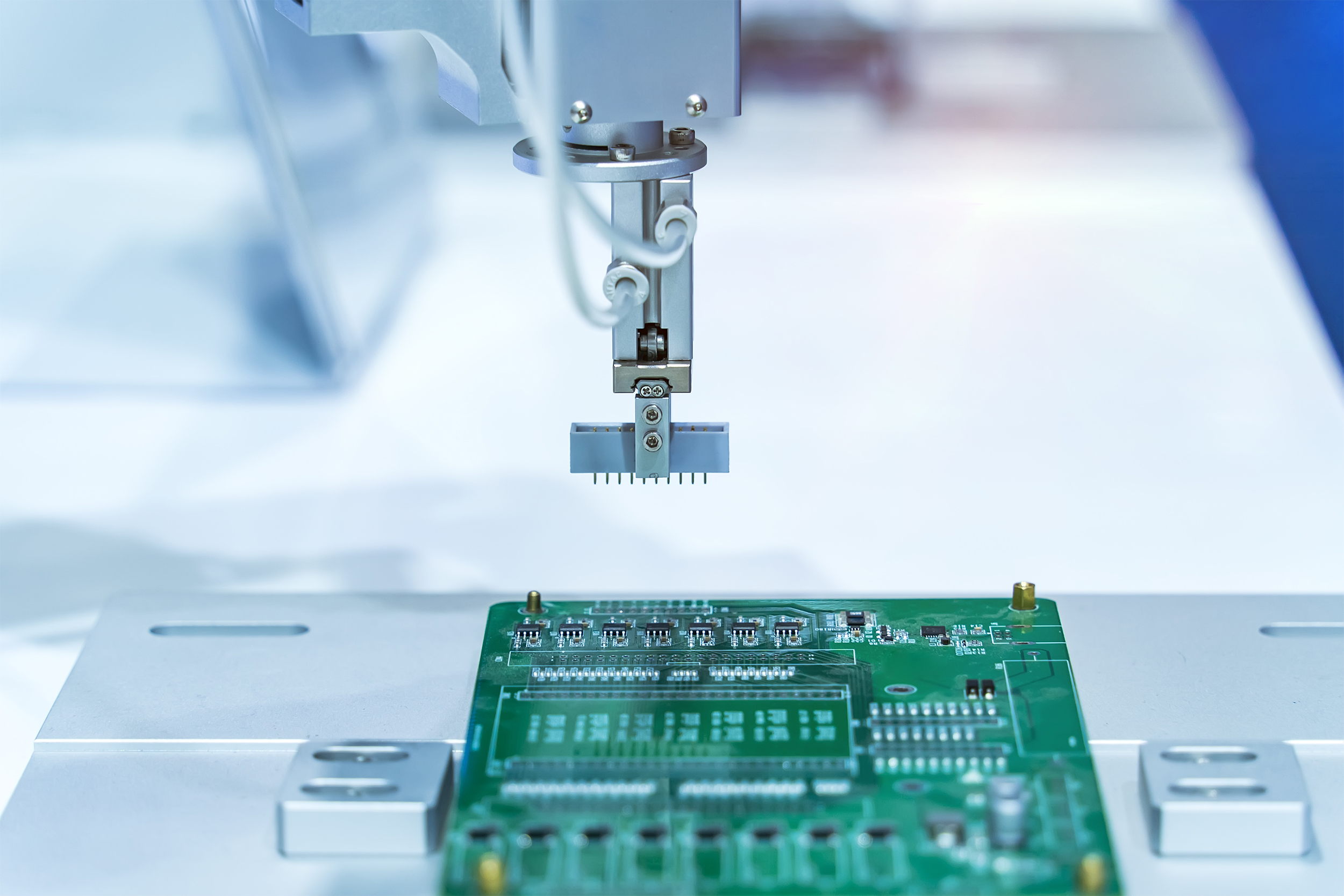

All of this means that, despite a tight few years, the semiconductor industry is poised for growth. Fabs need to be ready for increased demand, while simultaneously staying abreast of the latest technology and being nimble enough to pivot when the market demands it. Factory automation is helping chip manufacturers to accomplish this daunting slate of tasks by streamlining production, decreasing waste and cost, and driving the leading edge of manufacturing capabilities. Here’s how.

Business process re-engineering

In many cases, cost and logistical hurdles push fabrication plants to limit the scope of their automation efforts to spot solutions: handling a particular task on the production line, in the warehouse, or transporting product between areas of the facility. Partial automation can and does provide significant efficiency gains to a fab, but a major benefit of full-scale automated systems is the integration of advanced decision-making capabilities with the plant’s production line.

With real-time data inputs, process control and manufacturing execution systems can proactively plan a fab’s capacity based on tool availability, and can adapt on the fly to changes in demand, equipment errors, and bottlenecks. Whether a customer unexpectedly scales up an order or a maintenance window is approaching on a wafer handler, automation software acts as a central collection point for this capacity-planning information and reassigns resources to achieve on-time delivery.

Consistency and throughput

Robotic material handlers have been providing consistent, precise execution in all types of manufacturing facilities for decades. While workers’ energy levels and focus naturally vary, chip production especially requires repeatable precision that doesn’t waver. Automation is, and has long been, an excellent option for freeing up workers to handle more complex, creative tasks.

But with demand surging, fabs are also looking for ways to increase throughput and do more with the resources they have. Increasing automation gets fabrication plants ever closer to the ideal of lights-out manufacturing, ensuring a steady flow of product with a minimum of downtime. Critical to this goal is quality control: the ability to integrate data from inspection and metrology systems, as well as real-time status information from production line equipment, and interpret that data to identify and correct for faults. Catching chip flaws early means a minimum of wasted materials, which reduces cost and increases sustainability.

Sensitive material handling

The predictability—and controllability—of automated systems makes them ideal for cleanroom environments. Everything that enters and exits a cleanroom presents a possibility for contamination, and human personnel are by far the most significant source. Robotic material handlers with low-particulate surfaces and shielded electronics, and which need to leave the cleanroom much less often than workers, provide a fab with much greater control over its clean environment. Less contamination means less wasted material and effort, and a leaner and more cost-effective production process.

The decision-making capabilities of a fully automated system can also respond in real time to the time-sensitive needs of chip production, preventing queue time violations in the production process. Tool availability planning reduces the chance that a bottleneck will build up anywhere along the line, causing chips to miss the window for their next processing step and requiring them to be reprocessed or scrapped.

Warehouse efficiency

Automation can also streamline fabrication plants’ warehouse operations. Track-and-trace systems make sure that tools, supplies, and finished products stay on the radar, reducing downtime spent looking for lost items or redundant activity when a component goes missing. Automated storage and retrieval systems optimize available space and both pack away and retrieve items simply and efficiently, saving all-important floor space for valuable manufacturing activity. And moving supplies and products to and from the cleanroom requires handling that is both delicate and efficient; automated transportation systems can ensure a reliable pipeline.

This frees up personnel for other, more complex work, and forestalls safety risks from storage equipment or injury from repetitive tasks. It also allows warehouse operations to stay nimble, able to pivot between activities and scale up or down as demand requires. In an industry where on-time delivery is key to customer satisfaction, the flexibility that automated warehouse functions provide is an enormous advantage.

Full automation is preparing fabs for growth in the semiconductor industry.

The electronics-manufacturing market is starved for necessary components, and demand is growing for locally-manufactured chips. Fabrication plants need to be agile in order to take advantage of a changing industry landscape. The impact of automated systems in a fab encompasses every aspect of production, from business process engineering to warehouse management. When high visibility into production line activity combines with advanced automated decision-making and responsive equipment, fabs can plan activity early, catch errors and adjust on the fly, reduce bottlenecks and scrap, and deliver product right on time.

Eagle Technologies is ready to assist you with finding the right automation solution for your semiconductor fabrication plant. Whether you need spot solutions to increase efficiency transporting materials to and from the cleanroom, or are seeking a fully automated implementation to transform your facility, Eagle has the expertise to support you. Growing the domestic chip industry is both a government priority and a business imperative. Contact us today to explore how you can grow with it.

![]() Connect With Eagle Technologies LinkedIn

Connect With Eagle Technologies LinkedIn

Eagle Technologies, headquarters in Bridgman, MI

Eagle builds the machines that automate manufacturing. From high-tech robotics to advanced product testing capabilities, Eagle offers end-to-end manufacturing solutions for every industry.