Automated processes to control the timing, weight, volume, and application are critical capabilities in factory automation.

Multi-stage automated assemblies rely on a series of diverse processes to accurately and efficiently turn out high-quality products. Among these technologies, one of the most versatile is that of automated dispensing. Used across industries to dispense everything from powders and pellets to liquids and aerosols, it would be difficult to perform many automation projects without it. In many cases, dispensing a product is the entire purpose of the automation.

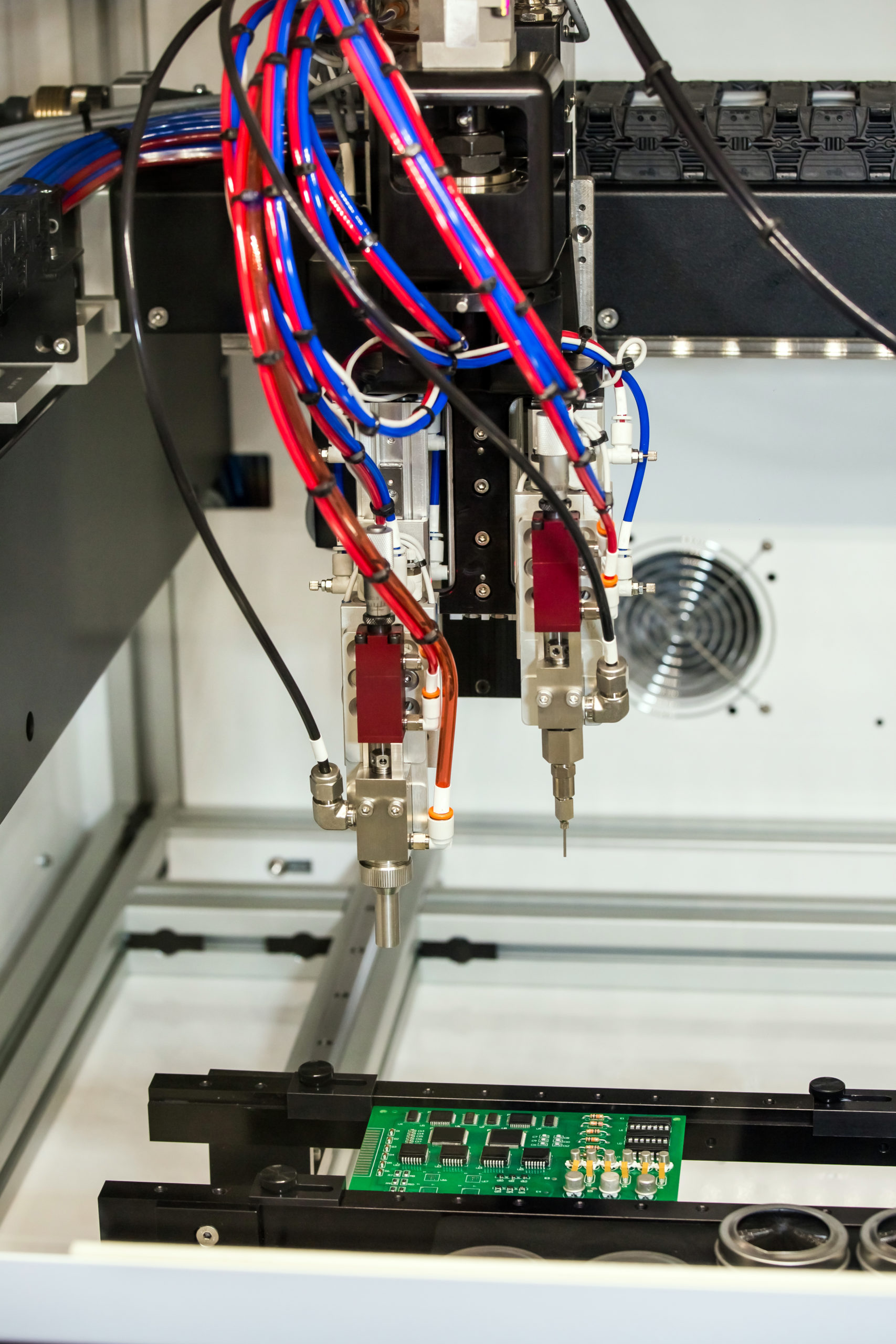

While dispensing technology is nothing new, it must meet increasingly high standards for accuracy, precision, and repeatability in order to maintain production quality—especially in complex modern applications such as electronics and automotive assembly. To achieve this, dispensing equipment uses mechanical timing and portioning mechanisms, as well as advanced sensors that can measure flow and weight and detect any anomalies in output.

For as ubiquitous as automated dispensing may be, there are many applications where implementing requires the utmost care and attention to detail, including ones where the material being dispensed is volatile or costly, where the place of application is hard to reach, or when consumer safety is at stake. The following are six use cases for dispensing technology that depends on high-quality automation technology to achieve manufacturing excellence.

1. Filling prescription medications.

Many pharmaceutical companies rely on automation to fill high volume prescriptions. The challenge with this automation lies not in the dispensing technology itself, but in the quality control measures which must be put in place to ensure the right medications go in the right bottle, and that these are properly dosed and labeled.

Dispensing technology can be combined with other automation technologies to package a range of medications, from pill bottles to blister packs to vials of liquid.

2. Dispensing powders into munitions.

In automated munitions manufacturing, filling a casing with the correct amount of charge is one of the most sensitive and crucial. Not only is the propellant (gunpowder) highly explosive by nature, but any mistake in measurement could lead to a dangerous production error with potentially fatal consequences.

Dispensing technology in munitions can increase output with lower costs, but it must be combined with security measures to protect manufacturing operators as they handle the equipment, and quality control checks to ensure everything has loaded properly.

3. Portioning food products.

Most of us have seen footage of factory automation in the food industry. Whole television programs have been based around showing viewers an inside look at the way familiar food products are made, from chocolate bars to bottled beverages.

The range of ingredients in food production—and the need for precise temperature controls—makes some of these automation project more challenging than otherwise. However, the need to keep equipment sanitary throughout the process adds an extra layer of complexity to the project. This means that dispensing automation in the food industry not only involves food products themselves, but automated cleaning cycles to keep production sanitary.

4. Applying bonding adhesives.

The variety of adhesives used across industries requires an equally broad range of application techniques. Yet the one thing each of these uses has in common is the use of dispensing technology to apply the adhesive to each component accurately and in the correct dosage. Too much or too little adhesive can lead to a weak bond, while poorly placed adhesives can degrade product quality.

Fortunately, today’s dispensing technology is so precise that it can apply microscopic doses for even the most miniaturized devices. This capability is especially crucial in electronics manufacturing, where components are both particularly small and delicate.

5. Lubricating difficult joints.

Lubricants are used in a range of assemblies to reduce friction between moving pieces, prevent corrosion, and extend the product lifespan. However, the right lubricants must be chosen for each job, along with the dispensing method that will be most effective for the application. For instance, because oil is a liquid, too much applied in one place can lead to leaks and drips. And because grease is thicker, it is more likely to become clogged if a valve with too narrow an opening is used.

Lubricants must also be applied accurately, and at times in narrow or hard to access places. Precision automation can not only expedite the process, but help the lubrication reach joints or gears in locations that would be difficult to reach manually.

When your production processes depend on accuracy and precision, turn to an automation partner, you can trust.

The technology behind automated dispensing is not hard to achieve. The difficulties behind it lie in its implementation—in the choices made when developing an assembly process, and in the safeguards put in place to prevent accidents or manufacturing errors from taking place. Many of the challenges also involve the materials being dispensed—especially volatile substances that may put factory operators at risk, or adhesives which may clog machinery and lead to poorer production outcomes.

This is why it is so essential to work with an automation partner who understands the technology completely, and who has experience using it in complex applications. At Eagle, our cross-industry expertise has given us plenty of opportunities to master automated dispensing. From munitions to prescription pharmaceuticals to bonding and lubrication, we know when and how to incorporate our technology safely and effectively.

If you need an automation partner to design an assembly for your product, talk to us. Our project history demonstrates that we have the expertise to design equipment that will meet your requirements.

![]() Brandon Fuller, Eagle Technologies

Brandon Fuller, Eagle Technologies

Eagle Technologies, headquarters in Bridgman, MI

Eagle builds the machines that automate assembly line manufacturing. From high-tech robotics to advanced product testing capabilities, Eagle offers end-to-end manufacturing solutions for every industry.