Factory automation has been a dominant force in economies around the globe for decades, but with new technologies emerging every year, leaders across every industry are feeling the pressure to adopt innovative solutions to age-old challenges. At Eagle, we have made it our mission to become experts not only in automation, but in each of the Industry 4.0 technologies that are driving this change forward.

As leaders in our field, we have done our utmost to ensure our facilities are equipped to handle our customer’s needs. Our manufacturing centers are strategically positioned along the Chicago–Detroit corridor. Combined, they offer over 250,000 sq.ft. of engineering space in state-of-the-art, climate-controlled facilities, while our new location in the Metro Detroit area expands our advanced testing capabilities in the region.

-

Eagle’s Expertise:

90M Annual Sales

50 Years of Automated Systems

1,000 Installations Worldwide

280K Square Feet of Facilities

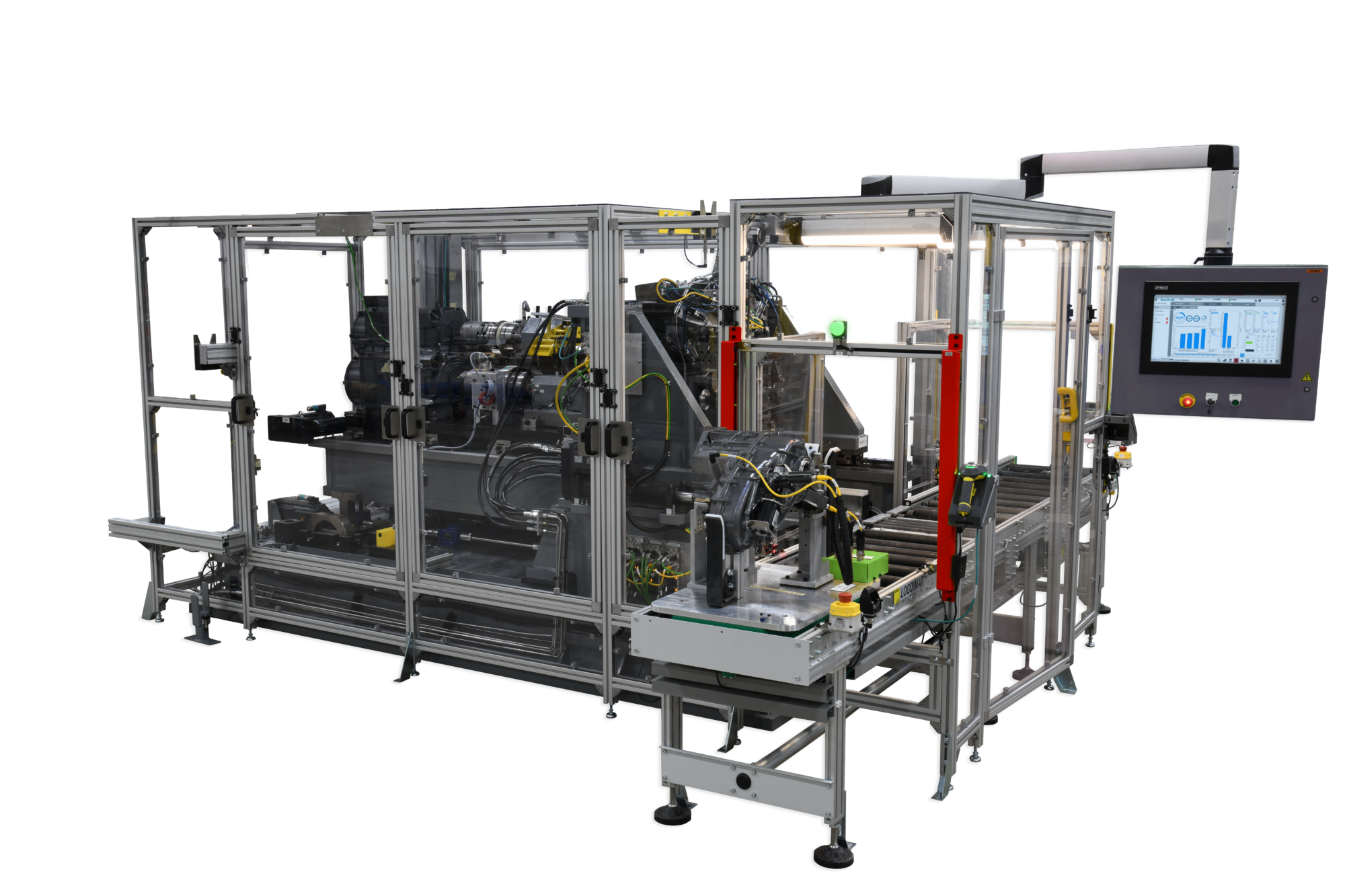

EAGLE’S FACTORY AUTOMATION CAPABILITIES INCLUDE:

- Full range of Industry 4.0 technologies

- Automations for material joining, removal, and handling, as well as dispensing and packaging

- Precision robotic solutions from FANUC, Yaskawa Motoman, Denso, ABB, KUKA, and more

- Advanced test systems with industry-specific solutions

Advanced assembly simulations to demonstrate proof of concept.

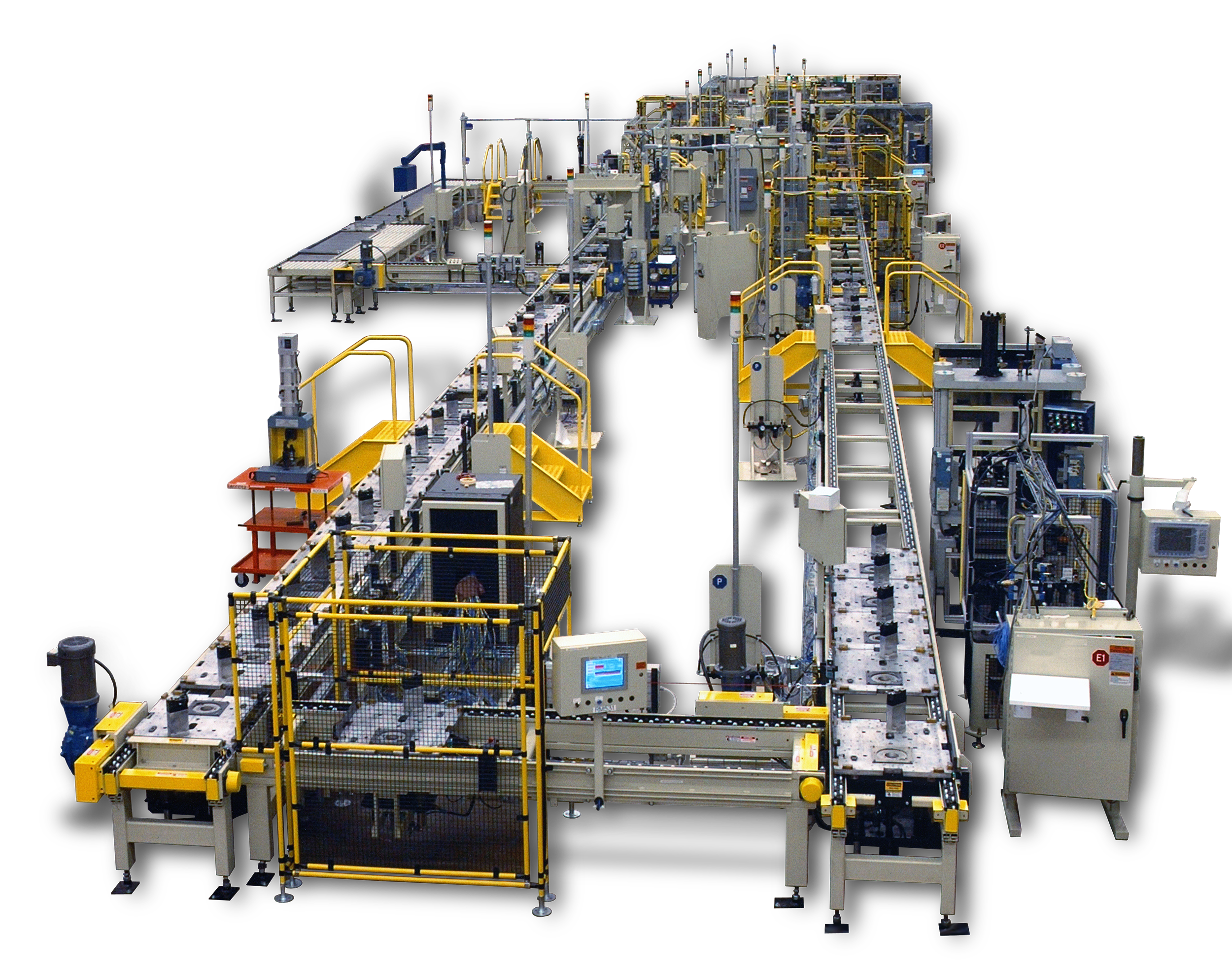

A tremendous amount of engineering goes into each of our assemblies, even before production has begun. Our Applications department uses high-end simulation software to demonstrate proof of concept and deliver more accurate estimates. Then our Engineering department uses simulations to fine-tune the assembly process to see how our design will operate on the factory floor.

The simulation process allows our team to discover areas of inefficiency, such as slow points in the assembly line, or areas where automated processes might interfere with each other. We then modify our design to make best use of every resource. As a result, we deliver highly efficient assemblies that often have a smaller factory footprint than our competitors.

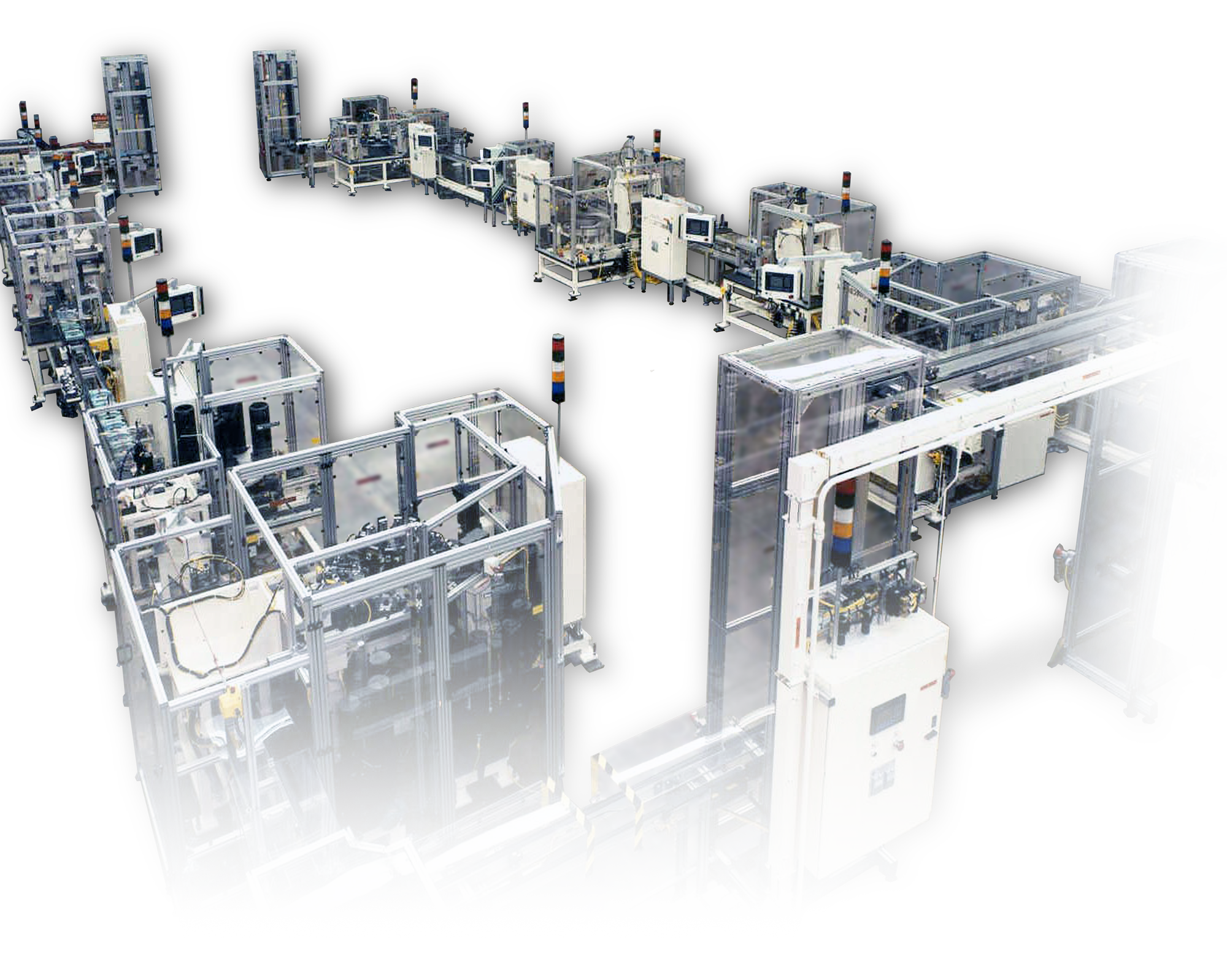

Factory automation experience in dozens of industries, worldwide.

Advances in robotics and other automation technologies mean that there are few industries that haven’t already undergone some form of automation. In fact, most industries aren’t yet taking full advantage of the benefits automation can bring.

At Eagle, our experience in factory automation covers nearly every sector, from automotive to health care, agriculture to consumer goods. We not only understand the special needs and challenges of these industries, but have experience working within regulatory standards.

“If you are looking for an automation partner for your company, Eagle has your back. We are stationed in locations around the globe, from the heart of American manufacturing in the Midwest, to the innovation center in California, and a new installation and support center in China. We also have global manufacturing partners stationed in Ireland and Mexico.”

—BATTERY TECHNOLOGY CUSTOMER

In-process or stand-alone automated testing.

Excellence by design can only be achieved with testing processes that are themselves designed to be foolproof. We can build advanced testing directly into the assembly process, so that any defect is spotted early in the process, or develop stand-alone testing solutions to validate the final product.

We also apply our rigorous testing standards to our own machines. When we develop an assembly, we first test the product output in our own factories to establish a baseline. Then we bring our testing equipment into the field, to each manufacturing plant, to run correlation tests. This ensures that our products perform as well in real-life operating conditions as they did on our manufacturing floor.

97% on-time delivery rate.

We understand that our customers depend on us to keep their production schedule on track. For this reason, we take seriously our own obligation to deliver assemblies to our clients on time and on budget.

We follow several internal protocols to ensure we meet our delivery deadlines. These include “lessons learned” debrief meetings with our team, regular Kaizen sessions to discover areas of continuous improvement, and reviews with 3rd party consultants to unearth areas where our team could be performing better. Together, these processes have helped us achieve a 97% on-time delivery rate—among the highest in our industry.

Contact Eagle Technologies to learn more about our robotic automation solutions.

If you are looking for a robotic automation partner for your company, Eagle has your back. We are stationed in locations around the globe, from the heart of American manufacturing in the Midwest, to the innovation center in California, and a new installation and support center in China. We also have global manufacturing partners stationed in Ireland and Mexico.

Contact us today to learn more about our capabilities, or come see for yourself by arranging a visit at one of our manufacturing locations.

Lets Talk.

Contact us and we’ll be happy to help!