Development NVH Tester

Eagle designed this tester for

- Transfer case shift characterization and validation.

- Characterization of transfer case coil resistance.

- Dynamic NVH analysis of the product utilizing order tracking.

- Functional validation of assembly.

- High Gage R&R (Repeatability and Reproducibility) and Correlation.

Challenge

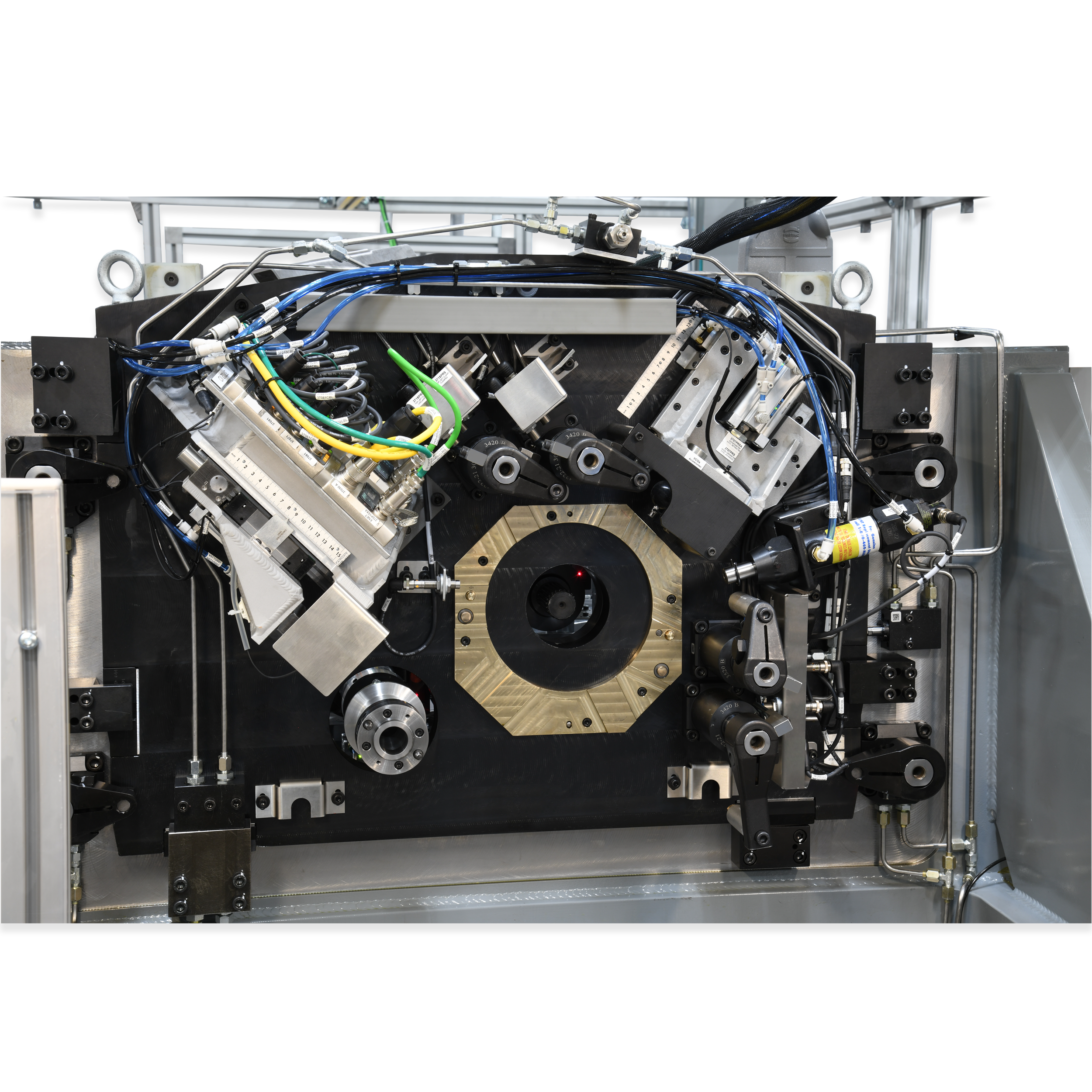

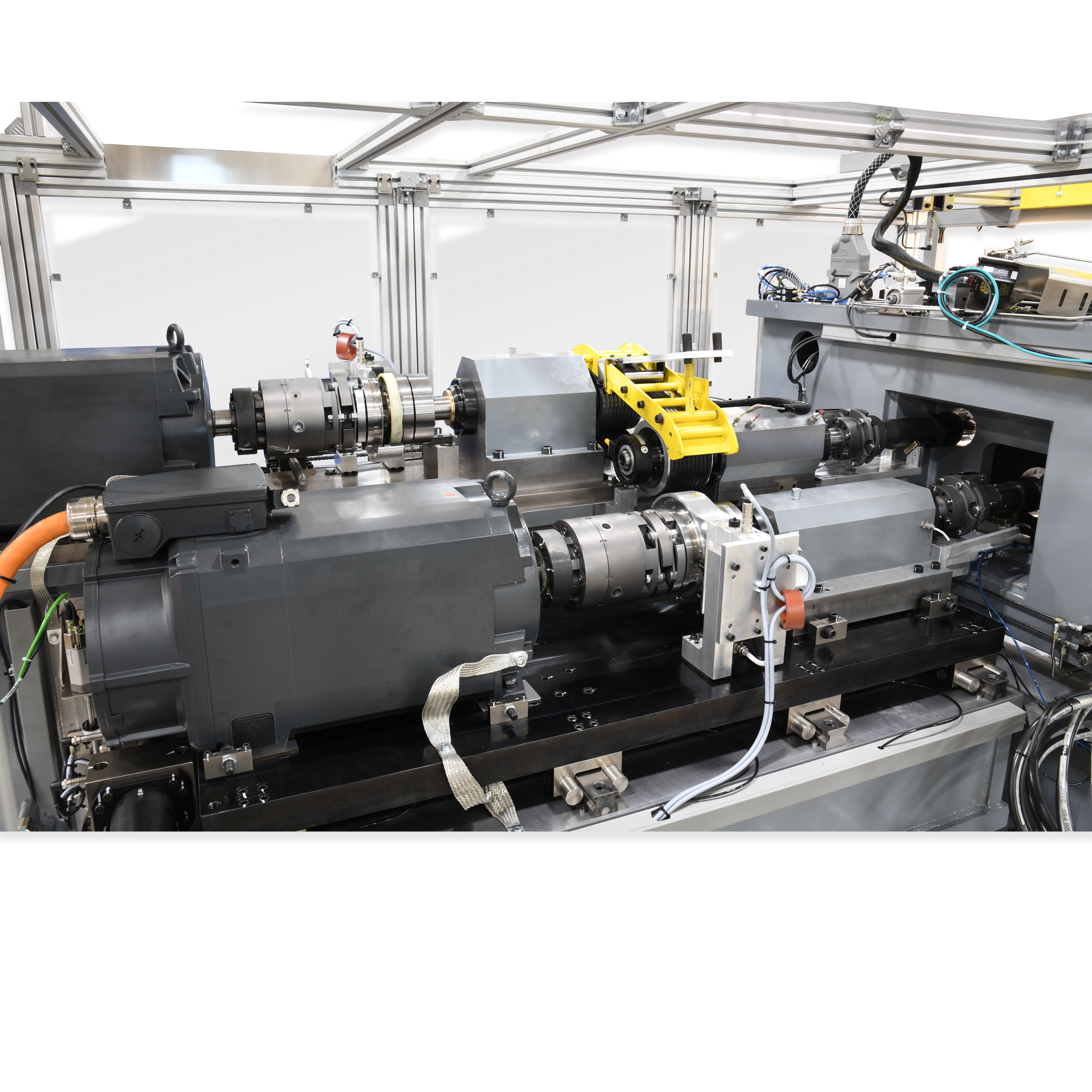

- Coupling of servo motors to the product in a restricted space)

- Flexibility to test different models with different physical dimension

- Minimizing vibrations on the machine

- Protection of the part and servo motors

- Fulfill safety requirements

Solution

- Compact footprint and modular design

- Custom mechanical design that allows moving the servo motors to adapt to the product dimensions

- 0-200 mm Lateral and Vertical adjustment on output

- Interchangeable fixtures designed for each model

- Belt-driven axis to allow coupling of servo motor in a restricted space

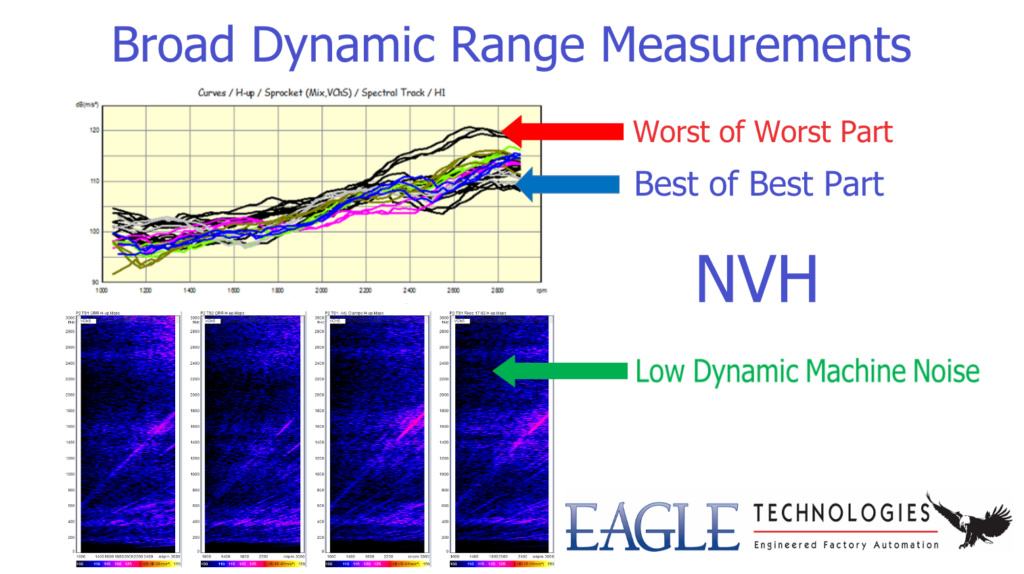

- Integration of 3rd party order tracking analysis

- Precision balanced driveline (G 2.5)

Results

- High repeatability and correlation

- Low first order dynamic energy

- Efficient cycle time

- Low factory noise

Test Capabilities

- 200 Nm applied torque (base speed)

- 5000 RPM Maximum input speed

- Dynamic Torque transducers

- Speed and torque modes

- NVH Squash Ball mounted accelerometers

- NIST Calibration and Traceability

Hardware & Controls

- Climate controlled 3-door 480 VAC Panel

- Single door test equipment panel

- Siemens Drives and controls

- Large touchscreen PC for machine control and test configuration

- MES integration

- Custom part interface circuit