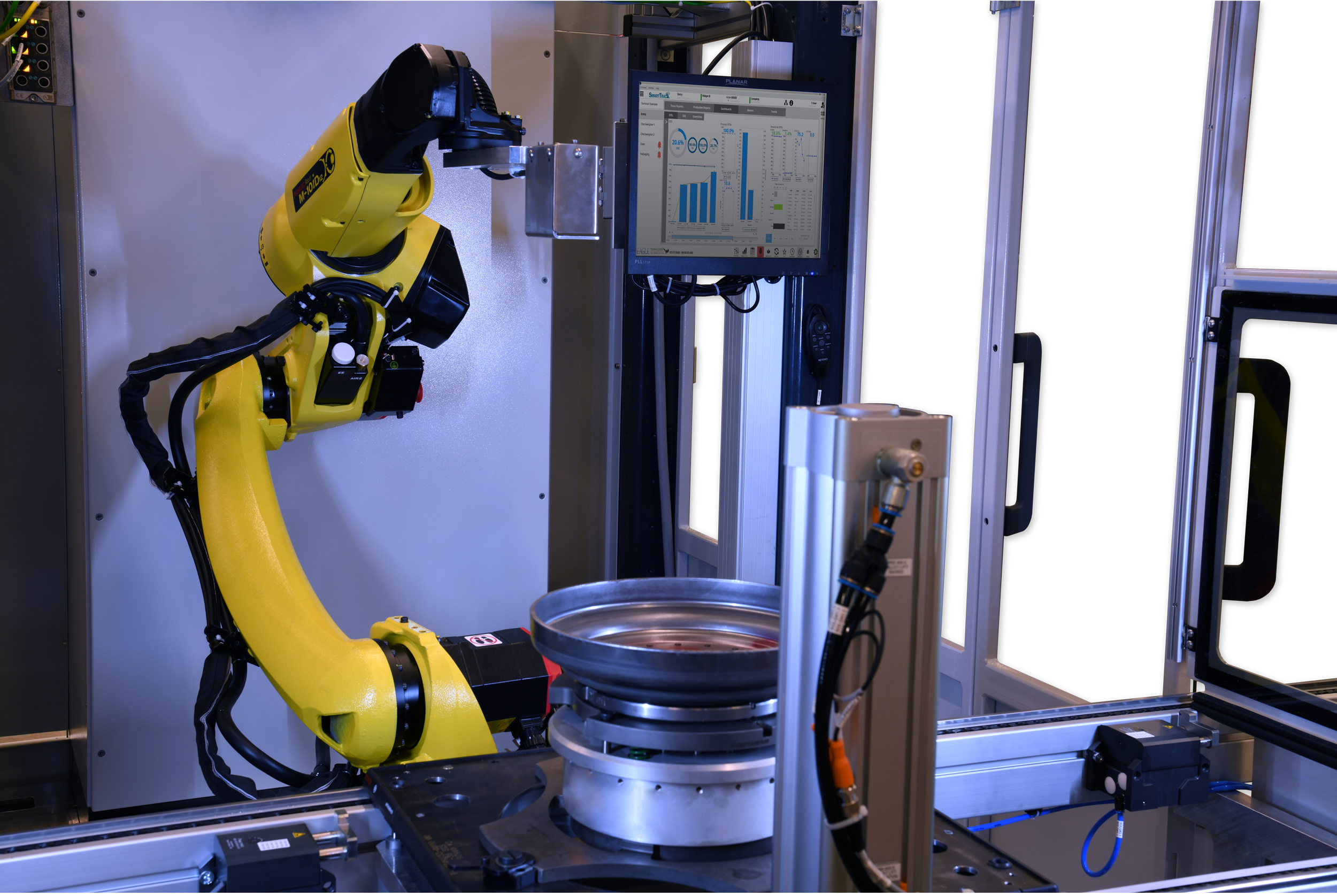

Many automated tasks that once posed seemingly insurmountable challenges are now easily within reach, thanks to visioning technology. For instance, components that previously had to be positioned with just the right orientation in order for an automated process to work no longer require such precision, because vision systems can see the component and adjust their process accordingly.

Similarly, vision technology can be used for inspection and testing. Vertical farmers can use mobile robots to detect when crops are ripe, and manufacturers can enable vision systems at key points on the production line to keep an eye out for visible flaws. Automated vision systems don’t grow fatigued the way human operators do, meaning they can stay online longer with lower chance of error.

At Eagle, we’ve worked with industry leaders to develop new ways to incorporate vision technology into assembly systems. Contact us to learn more about Eagle’s vision capabilities.