IMPROVED RELIABILITY THROUGH MANUFACTURING VALIDATION

Validation and assembly processes are proven cost savers for businesses. These additional quality control measures mean businesses are able to reduce scrap and rework costs and reduce expensive product recalls linked to manufacturing flaws.

We offer several validation tests to ensure the products manufactured by our automated systems meet design specifications. When conducting these tests, we bring our validation equipment to each factory site to compare on-location data against the results of our laboratory tests. These correlation studies demonstrate that the output from each factory meets the same high standards achieved by our own tests.

AIR VERIFICATION

Using compressed air, we can gather precise and reliable testing data about product performance by means of an inherently clean medium. By eliminating tests with dirtier and potentially hazardous wet materials, we can achieve cleaner, safer, and more accurate results.

Air Verification Capabilities Include:

- Fluid Pump Performance

- Valve Body Tolerances

- Accumulator

- Valve Seats and Seals

- Compressors

VISION VERIFICATION

Static vision applications are robust. However, when the application requires multiple model verification, component environments that change, a dynamic solution may be the best option. In many cases, Eagle will integrated a robot vision inspection station to save costs.

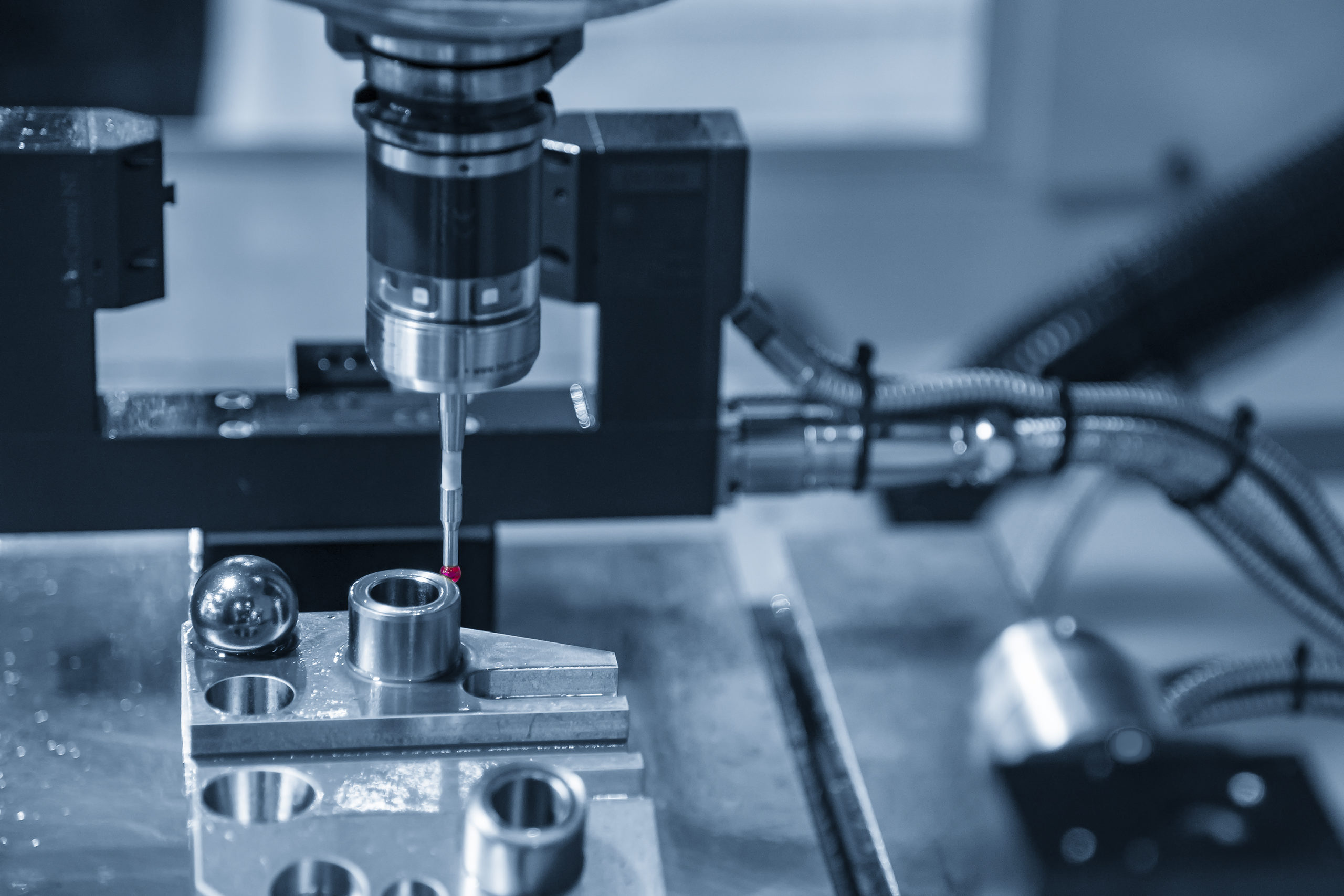

GAUGING AND MEASUREMENT

When your product needs to meet highly specific output measurements, we can create tests that ensure you achieve them. We use results from our measurements to dynamically adjust the assembly process, thereby reducing the costs of Work in Process (WIP).

SOLUTIONS

- Contact

- Non-contact

- Select Fit

- Vision Verification and Measurement

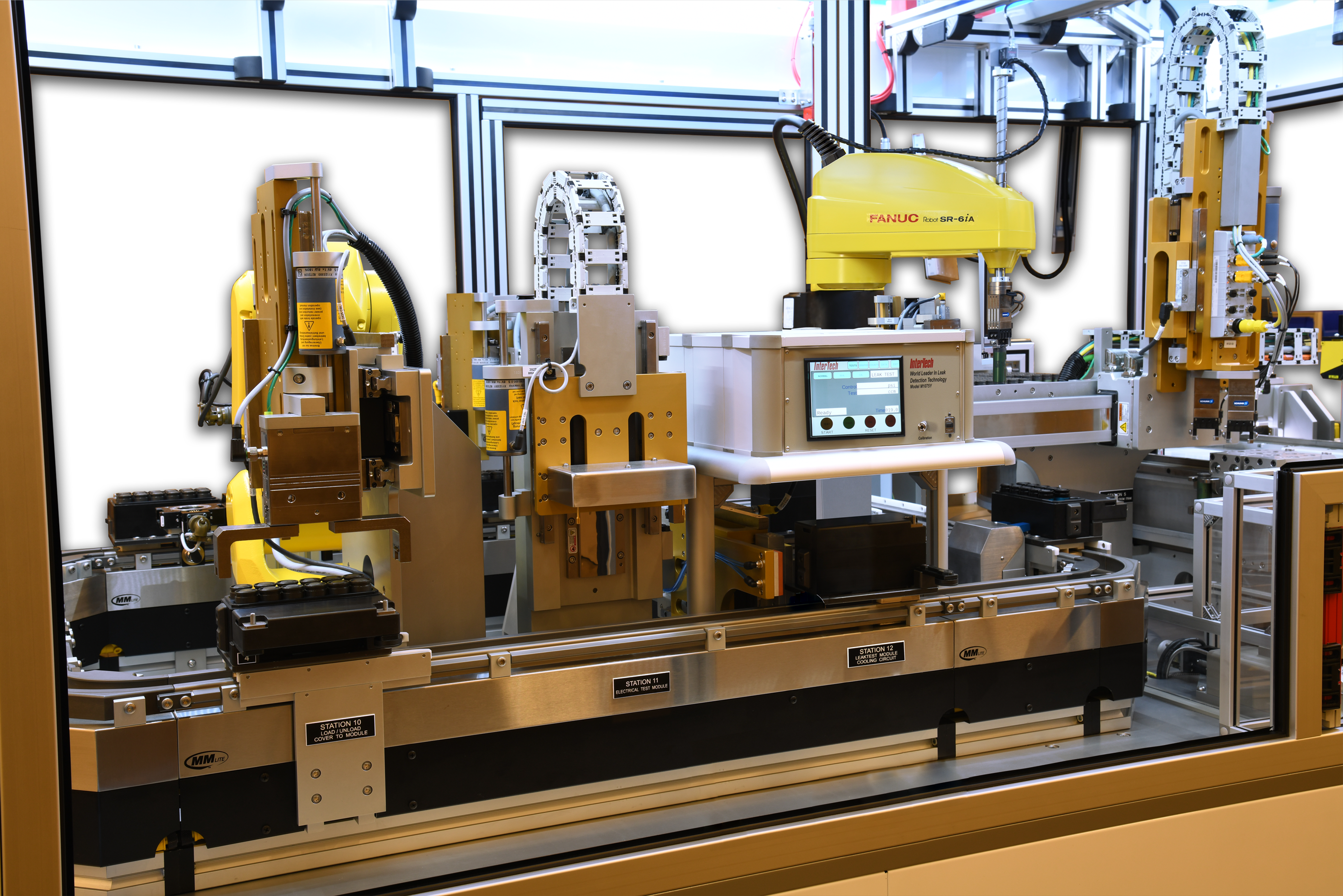

ROBOTIC GAGING VALIDATION

Using robotics with highly accurate vision and laser measurement devices is a flexible way to cover many products. Eagle integrates some of the most technologically innovative robotic and measurement systems in the industry.

PRODUCT TESTING

We can create custom product test scenarios for almost any situation. If you need your final product to withstand certain boundary conditions, we can build our procedures around those limits and create a repeatable test that your team can perform to ensure product quality.

Product Testing Capabilities Include:

- Crush

- Durability

- Electrical

- Functional

- Hardness

- Leak & Flow

- Destructive

GET TO KNOW EAGLE TECHNOLOGIES

Questions about Product and Process Validation?

Contact us and we’ll be happy to help!