COMBINING AUTOMATION TECHNOLOGY WITH ADVANCED ROBOTICS

All our automation technologies are enhanced when used in concert with precision robotics. Our machines can dispense adhesives and sealants, weld electronic wiring in place, deburr components, place pieces onto a conveyor belt, and load them into a tray for shipping.

Meanwhile, our vision-guided technology allows for more advanced tracking and verification capabilities, while also improving worker safety.

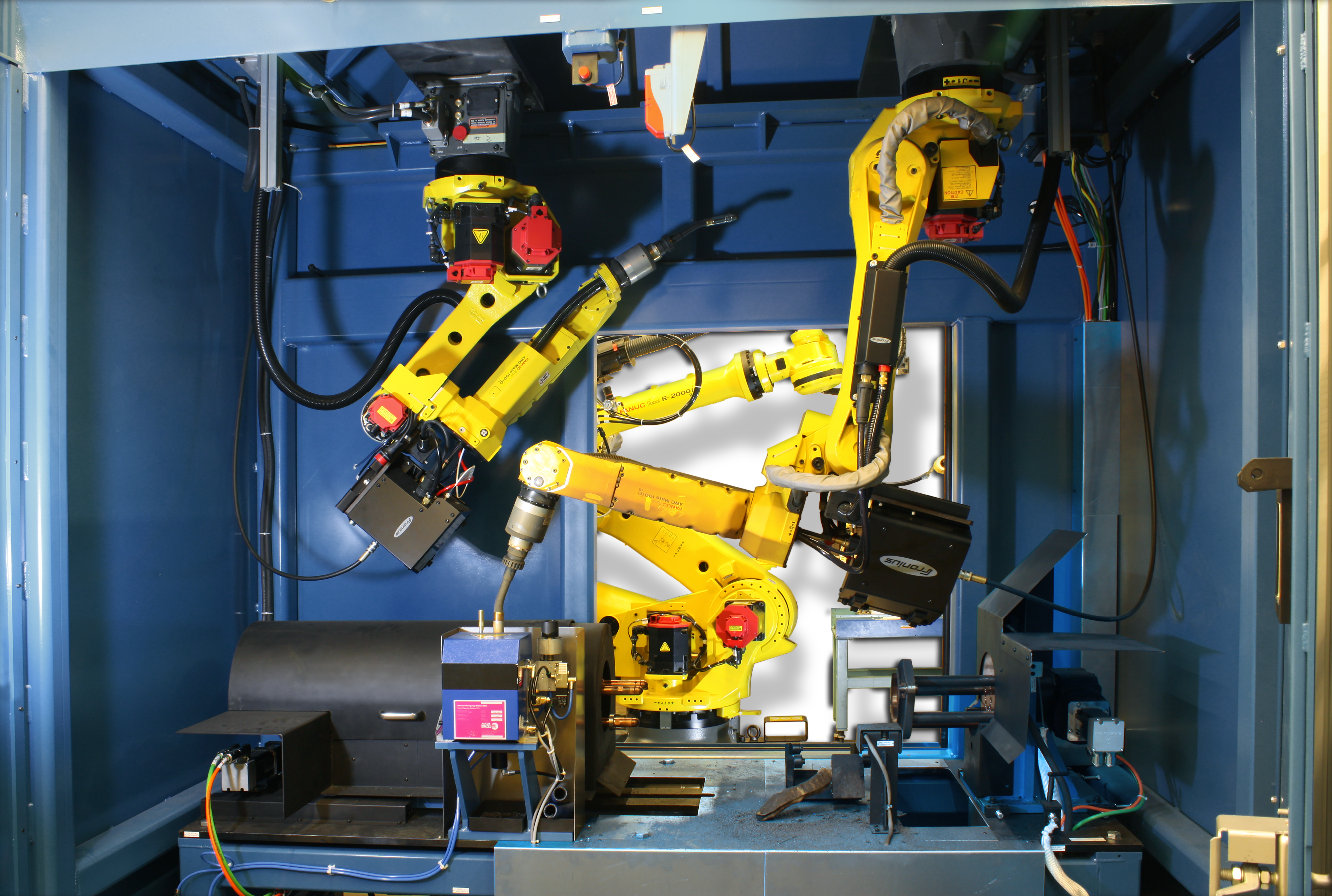

ROBOTIC WELD CELLS

We are equipped to provide complete robotic weld cells. As your complete automation solution, Eagle integrates all leading robotic solutions, including FANUC, Yaskawa Motoman, Denso, ABB, KUKA robots, and more. Whether your need is a small single robotic work station or a complete robotic assembly line of weld stations – Eagle has the solution for you.

ROBOTIC PRECISION DEBURRING

There are a variety of custom solutions for Robotic Deburr work cells.

Our basic solution includes:

- Multiple Compensating Electric Deburr Spindles

- Tool breakage sensors

- Vision Guided Robotic material handling of incoming product picking direct from customer racks

- Chip collection and removal

ROBOTIC SAW CUTTING

Large casting programs using 2 EOAT (Gripper & Saw)

Our basic solution includes:

- Multiple EOAT with high payload

- Tool breakage sensors

- Vision Guided Robotic Inspection and Part Location

- Chip collection and removal

ROBOTIC DRILLING

Eagle can develop a custom machine for your drilling process. Some applications require nimble engineering to accommodate applications with vast models. That is why our solutions for robotic drilling and high-speed part transfers are second to none in the material removal demands.

A typical solution can include:

- Multiple Compensating Electric Drill heads

- High-speed precision walking beam

- Torque and depth control and monitoring

- Tool breakage sensors

- Vision inspection

- Chip collection and removal

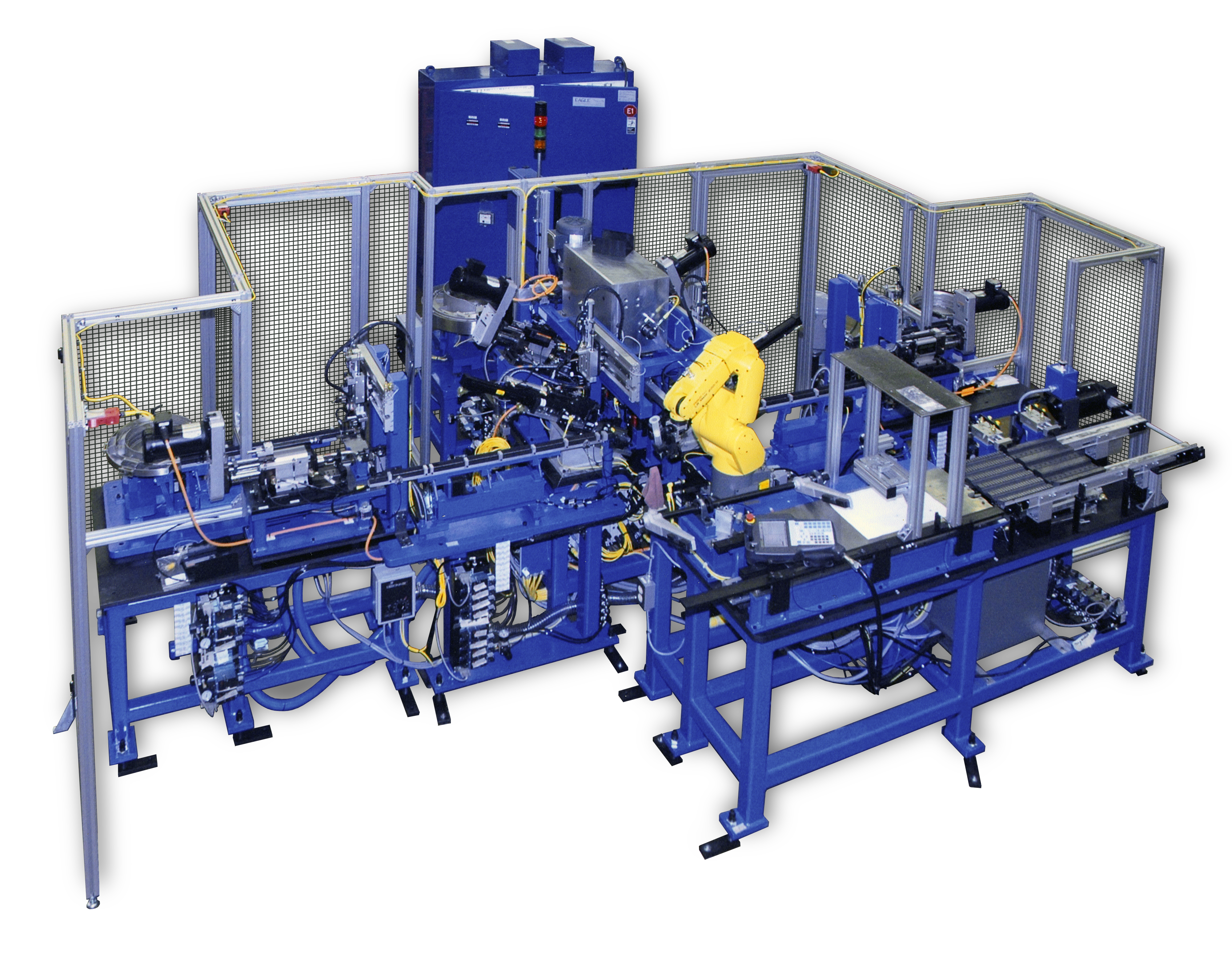

AUTOMATED ROBOTIC ASSEMBLY AND VERIFICATION

Robot automation allows for complex coordination between systems, leading to efficient, high-speed assemblies. Our robotics technology has been used to assemble complex electronics, heavy machinery, and even products made with volatile substances.

Visioning technology, with built-in cameras and integrated scanning, expands the range of robotic capabilities. Sensors allow robots to identify components, spot manufacturing errors, and track each piece as it moves through the assembly process.

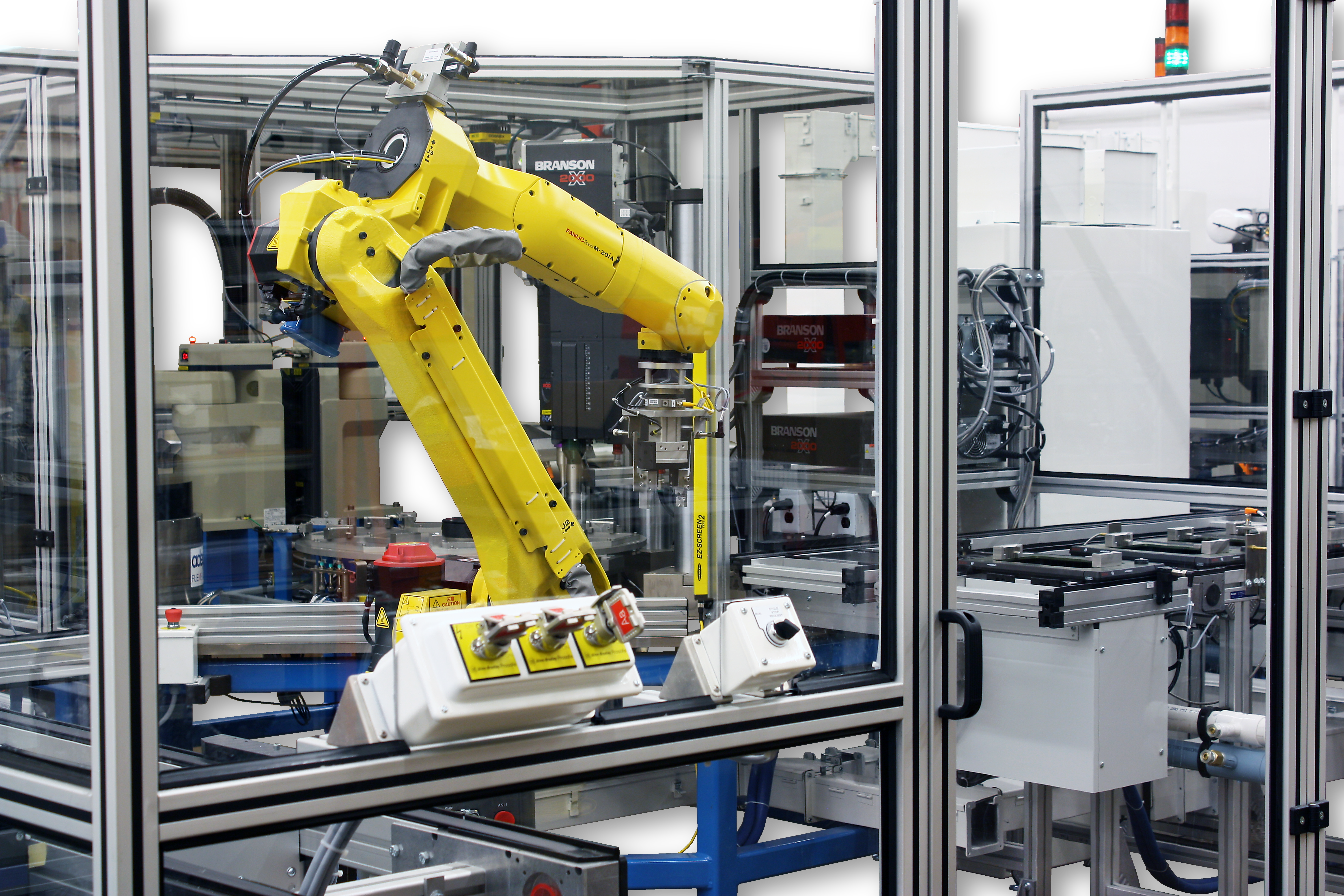

6-AXIS PICK AND PLACE TECHNOLOGY

Moving components from one conveyor system to the next, or preparing them for the next stage of assembly, requires precisions lifting, orienting, and positioning. Using high-tech sensors, our advanced robotics can lift and rotate parts along six axes for exact placement along the assembly line.

Our robots can handle picking and placing at high speed, even with delicate or fragile components. The result is a fully-automated system that can transport every piece of your assembly from start to finish.

ROBOTIC PACKAGING AND PALLETIZING

We offer a range of automated palletizing solutions so that your products can go from the factory floor straight to the loading dock. They include kit assembly, pallet loading, and case loading. We can even take the size and shape of a product into account in order to optimize how it is stacked and loaded for shipment.

SPECIALIZATION FOR ELECTRIC VEHICLE ASSEMBLY

Our expertise in the field of electronic vehicles qualifies us to build even the most advanced EV assemblies. In fact, our EV demo machine, on display to visitors at our facilities in Bridgman, MI, demonstrates how our robots work in conjunction with our automation technologies to manufacture complex parts.