FACTORY AUTOMATION FROM RAW CASTINGS TO FINISHED PARTS

We have automated manufacturing processes that begin with raw materials and end in parts ready to be assembled, validated, and shipped. Whether you need an automated solution to load and unload a CNC machining center, robotically machine, or to gauge critical dimensions, we can design and implement a manufacturing process from start to finish.

Material Removal Capabilities Include:

Technologies:

- Deburring

- Laser Ablation

- Drilling

- Reaming

- Milling

- Trimming

- Plasma Treating & Cleaning

Implementation:

- Fix-mounted spindle, robotically handled product

- Robot mounted spindle, fix-mounted product

- Automatic tool change for multiple edge/surface processing

- Laser measurement of tool wear

- Robotic fixture cleaning

- Vision Inspection of critical features

- Automated in-feed/out-feed conveyors

- Scrap containment and scrap handling systems

- Tool Cooling/Lubricating Systems

- Cleaning using Plasma Treat processing

Tools:

- Knurled Burr Bits: Straight, Cone, Ball end, Tear drop

- Fluted Cutters: Straight, Tapered

- Brushes: Nylon, Steel wire, Silicon Carbide

Materials:

- Aluminum

- Steel

- Plastic

Edges/Surfaces:

- Port Holes

- Fluid Passage Windows

- Gasket Surfaces

- O-ring grooves

Material Removal Spindles:

- Electrically or pneumatically driven

- Radially compliant, axially compliant, or rigid

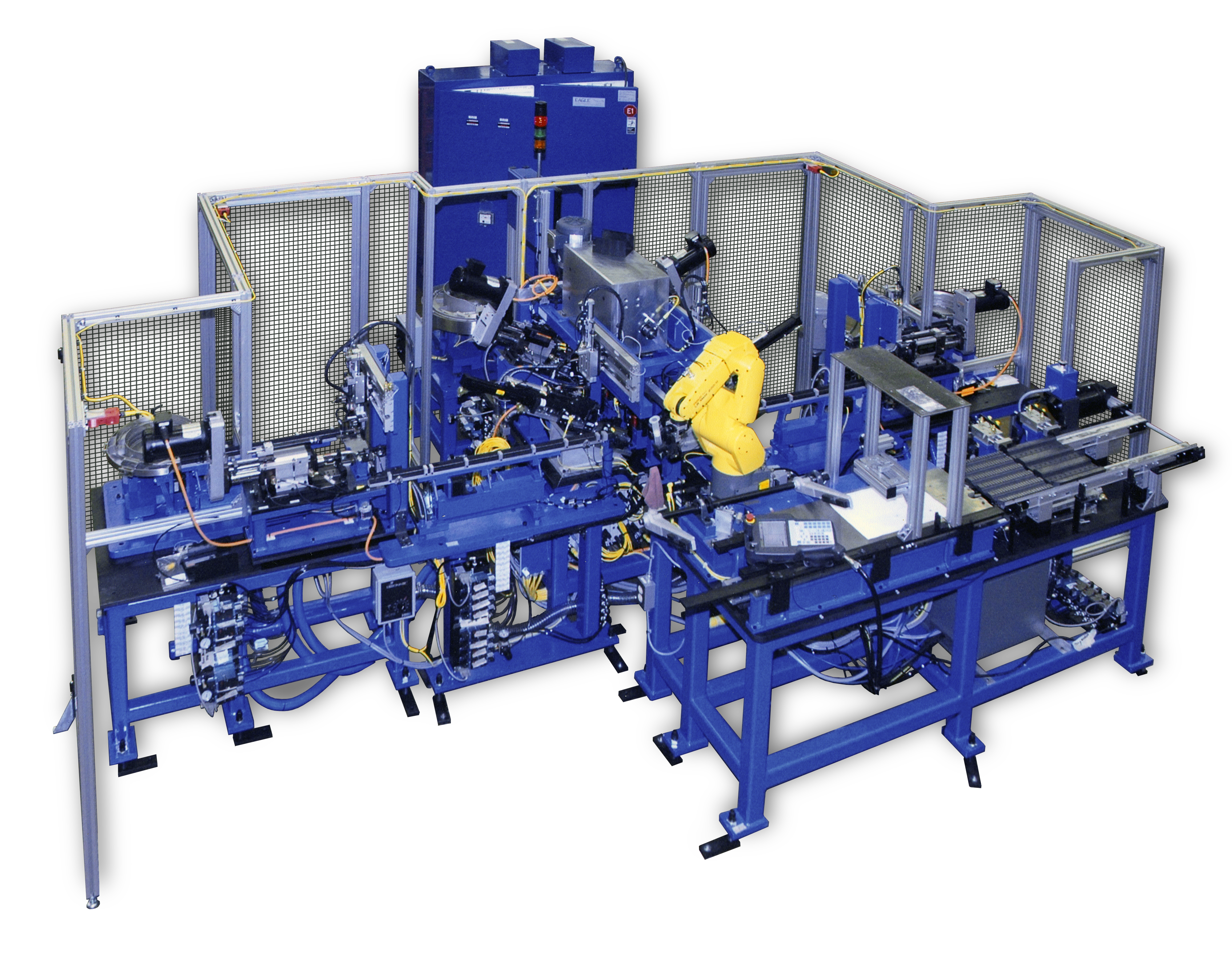

ROBOTIC PRECISION DEBURRING

There are a variety of custom solutions for Robotic Deburr work cells.

Our basic solution includes:

- Multiple Compensating Electric Deburr Spindles

- Tool breakage sensors

- Vision Guided Robotic material handling of incoming product picking direct from customer racks

- Chip collection and removal

ROBOTIC SAW CUTTING

Large casting programs using 2 EOAT (Gripper & Saw)

Our basic solution includes:

- Multiple EOAT with high payload

- Tool breakage sensors

- Vision Guided Robotic Inspection and Part Location

- Chip collection and removal

ROBOTIC DRILLING

Eagle can develop a custom machine for your drilling process. Some applications require nimble engineering to accommodate applications with vast models. That is why our solutions for robotic drilling and high-speed part transfers are second to none in the material removal demands.

A typical solution can include:

- Multiple Compensating Electric Drill heads

- High-speed precision walking beam

- Torque and depth control and monitoring

- Tool breakage sensors

- Vision inspection

- Chip collection and removal

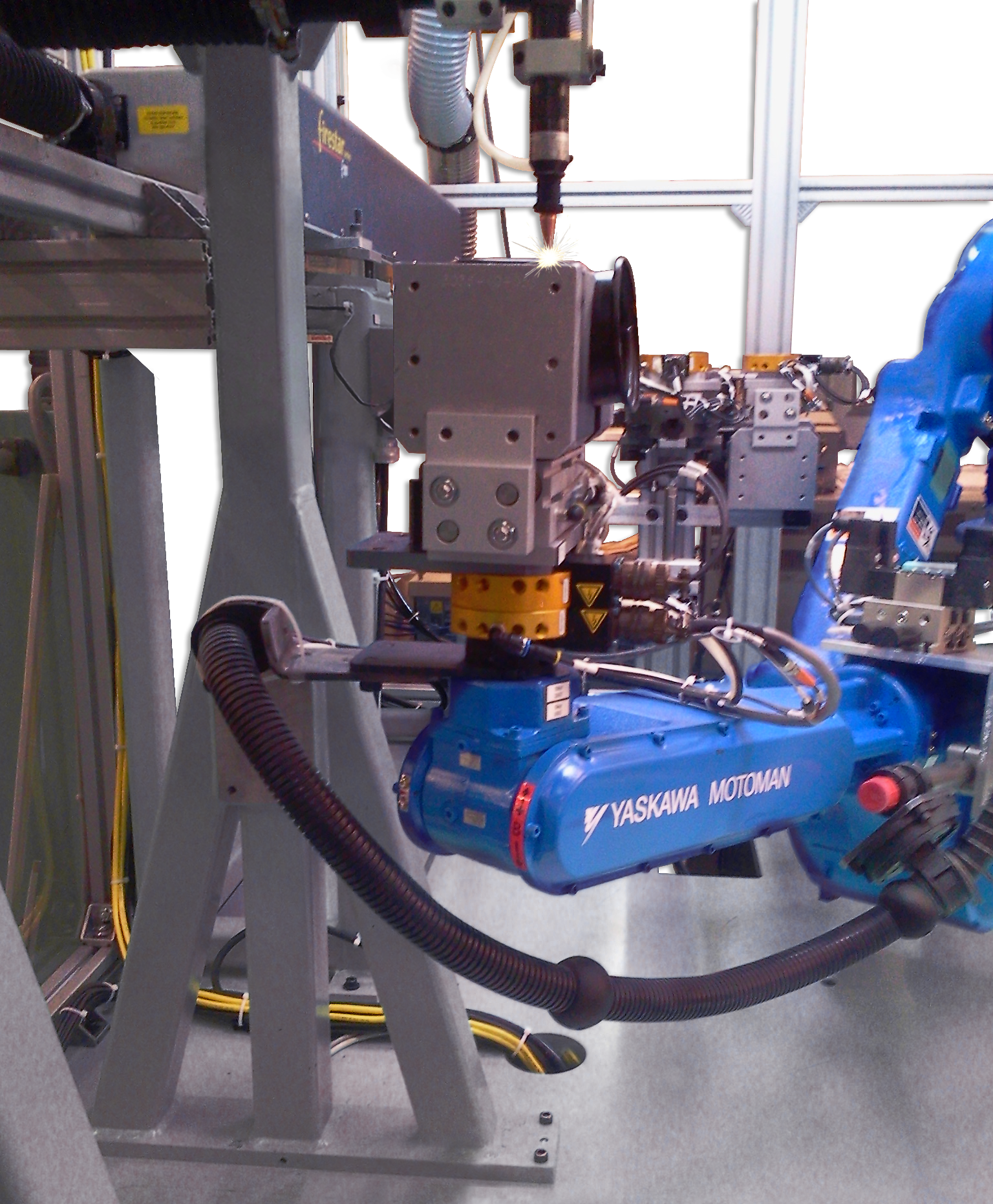

LASER ABLATION

Laser ablation is the process of removing material from a solid surface by irradiating it with a laser delivery system. Eagle uses laser technologies in many applications and with a large array of materials. Our experience from laser ablation removal of paint on radio bezel buttons to circuit boards identification – we have a solution for you.