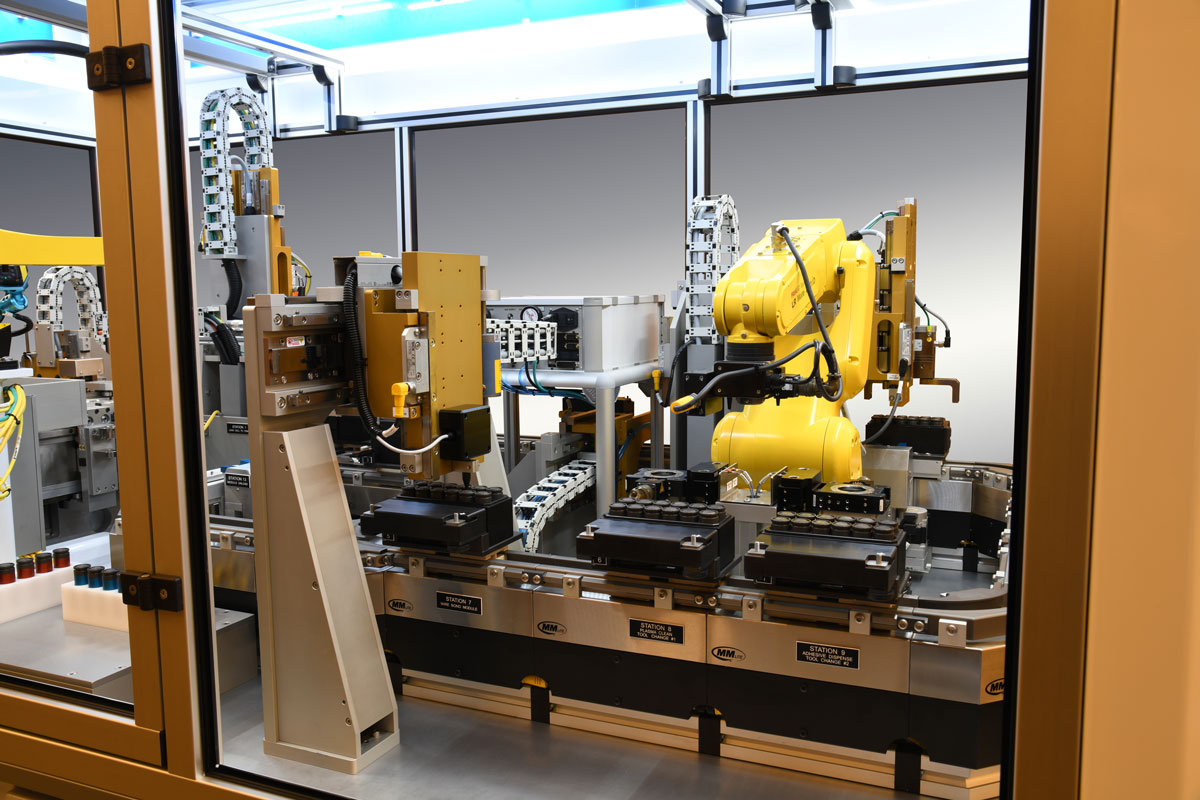

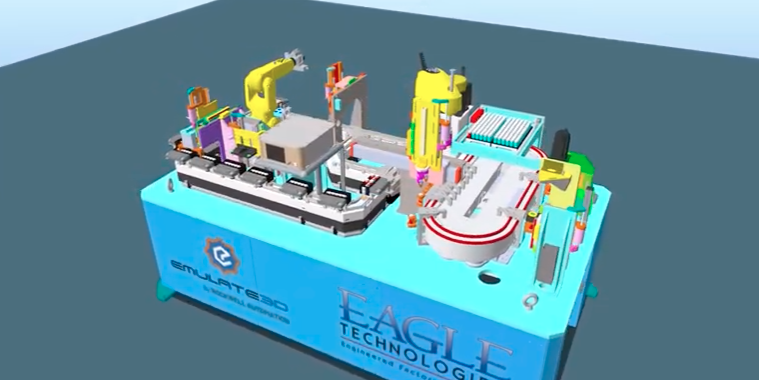

At Eagle Technologies, we have invested in engineers who are simulation experts. At the application level, we eliminate unknown variables by building 3D models for robotic simulation, and 2D discrete event simulations that allow us to trace how one change might affect downstream processes. During engineering, our team relies on simulation to fine-tune design details and get a head start on programming and debugging work.

Our implementation of automation simulation has had numerous positive results for our clients. We have reduced the turnaround time on our largest and most complex assemblies from a year or more to four or five months. By identifying design efficiencies, we have reduced the footprint of our designs drastically. And by demonstrating proof of concept early in the production process, we can confirm essential factors, such as cycle times and throughputs, allowing manufacturers to better prepare for their new assembly capabilities.

OUR SIMULATION CAPABILITIES INCLUDE:

- 3D robotic simulation powered by Emulate3D

- 2D discrete event simulation

Lets Talk.

Contact us and we’ll be happy to help!