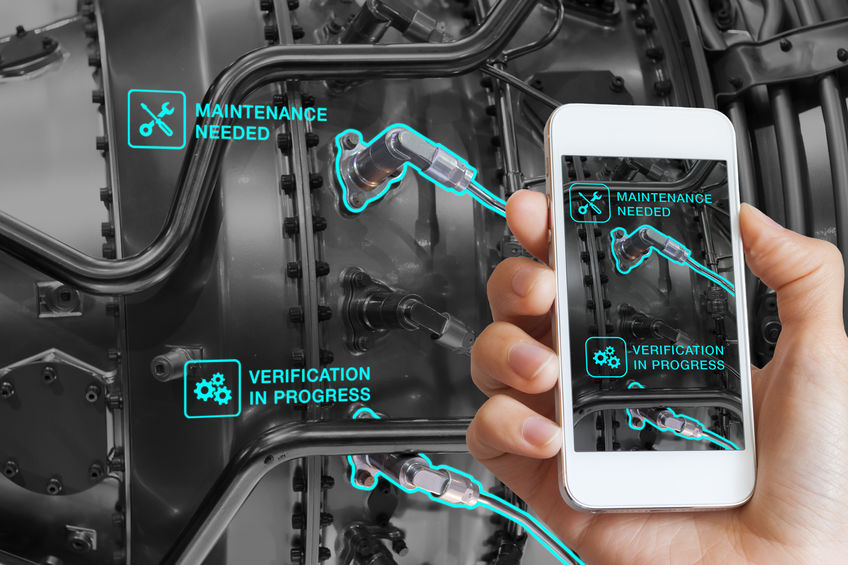

Eagle can integrate AR technologies into any point in our production processes. We can use them to help guide your operators through an assembly stage that requires manual production, integrate them as part of a quality control system to visually flag faulty parts, or link them to the IIoT to provide real-time data to operators as they walk the factory floor.

AR has several benefits in a factory setting. Visually relaying assembly instructions helps operators perform faster, thereby increasing production output. An AR system could spot a mistake made during assembly and alert the operator to an error before the part entered the production stream. And an operator who spotted a production anomaly while performing an inspection could access information about the machine in front of them without having to return to an operating station. At every turn, AR offers a means of improving quality and efficiency.

Lets Talk.

Contact us and we’ll be happy to help!