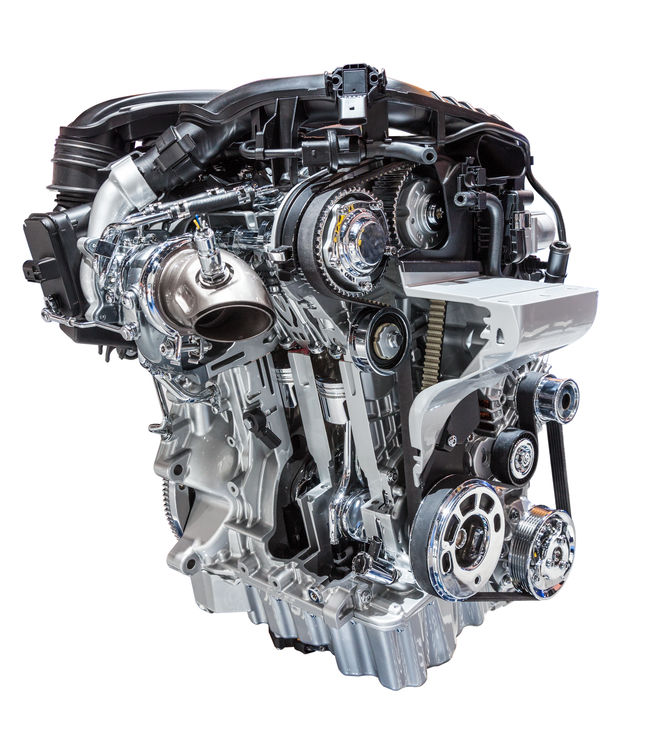

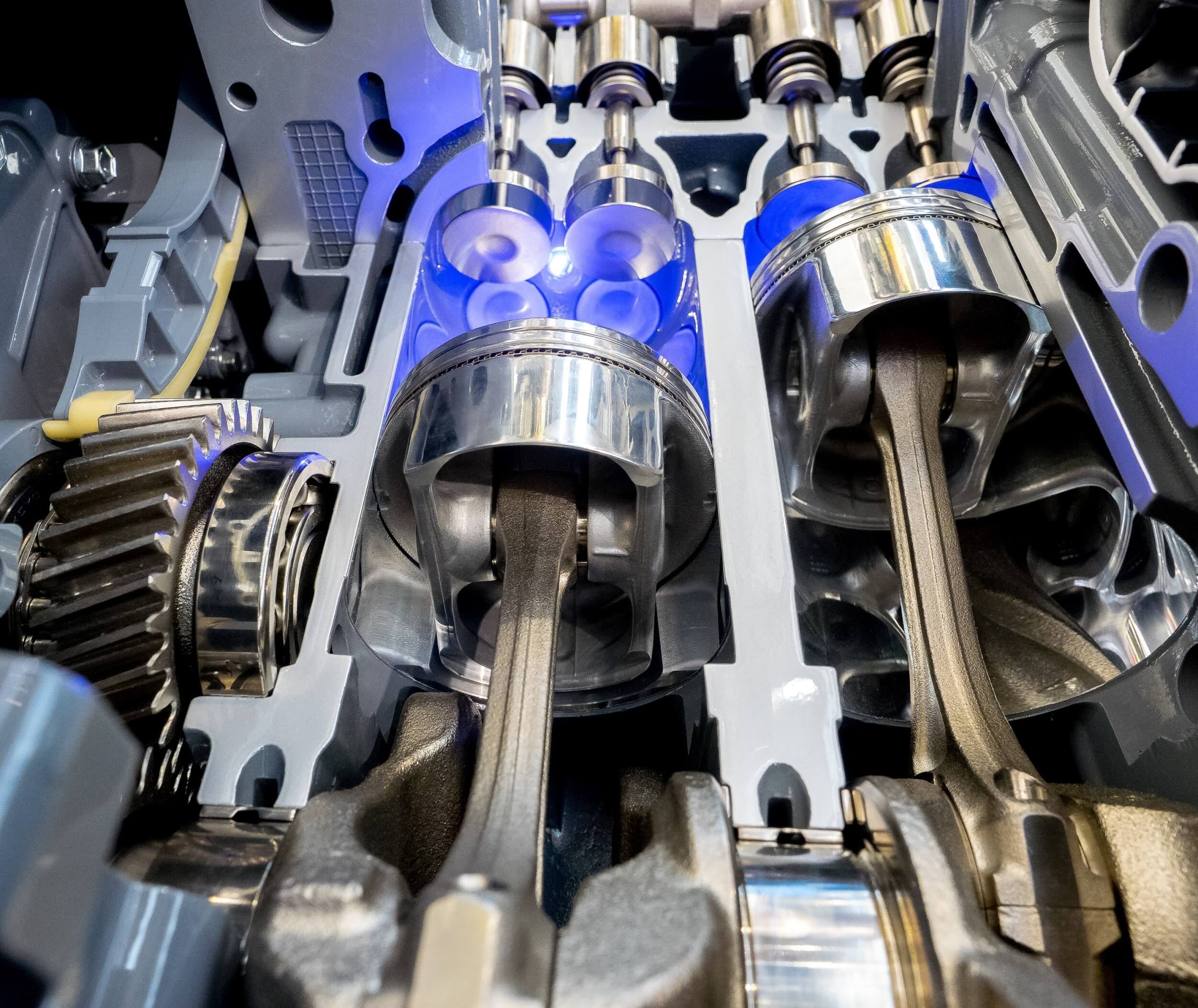

ENHANCED ENGINE EFFICIENCY AND PERFORMANCE

Horse power and fuel efficiency are two of the main factors related to engine performance that influence consumer purchasing decisions. The desire to improve these metrics has driven innovations in engine design. However, these advances must be verified through careful testing to certify that each new improvement meets engineering specifications and passes quality control measures.

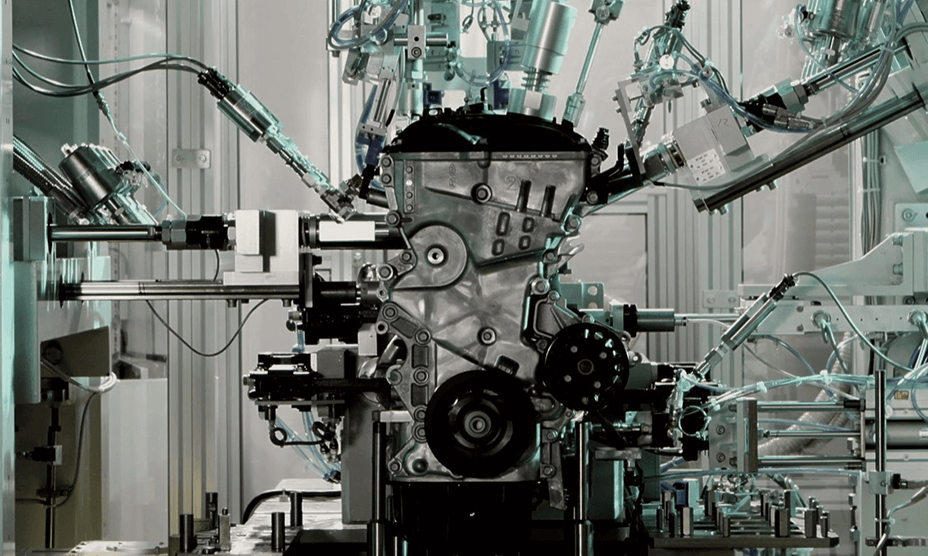

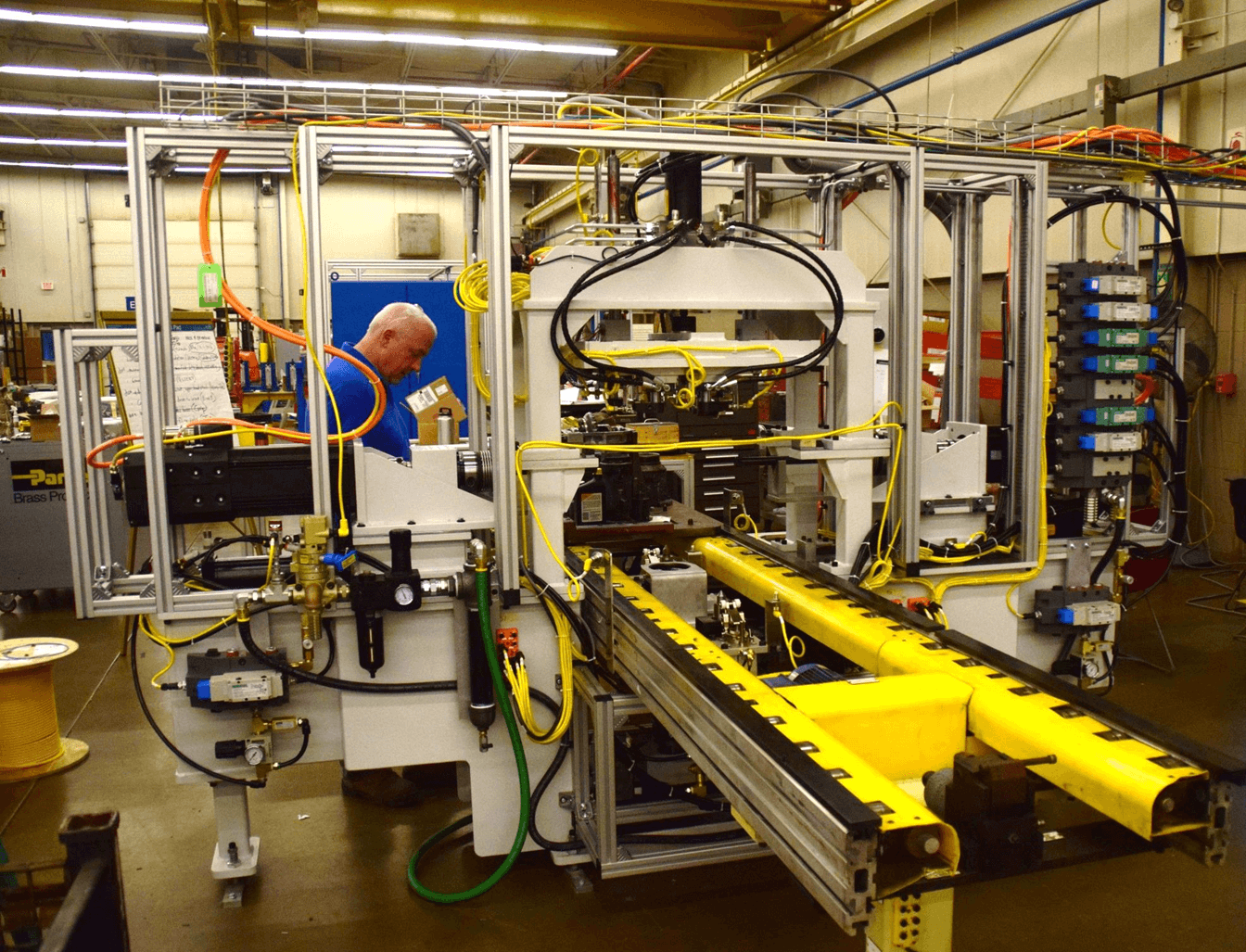

We run both hot and cold tests to gain the clearest understanding of how our engines are performing. Our tests either verify that the product is ready to go to market, or else identify production flaws that need to be addressed before production.

COLD

A cold engine test allows for more controlled performance measurements at both high and low speeds. Our cold test validates the engines primary functions, as well as sensors, cams, and pressures, while our advanced signature analysis systems provide a full characterization of the motor.

HOT

A hot test runs the engine regular operating conditions, measuring fuel efficiency, drivability, and torque speed performance. Metrics from this test can be measured against design requirements to ensure they meet quality control standards.

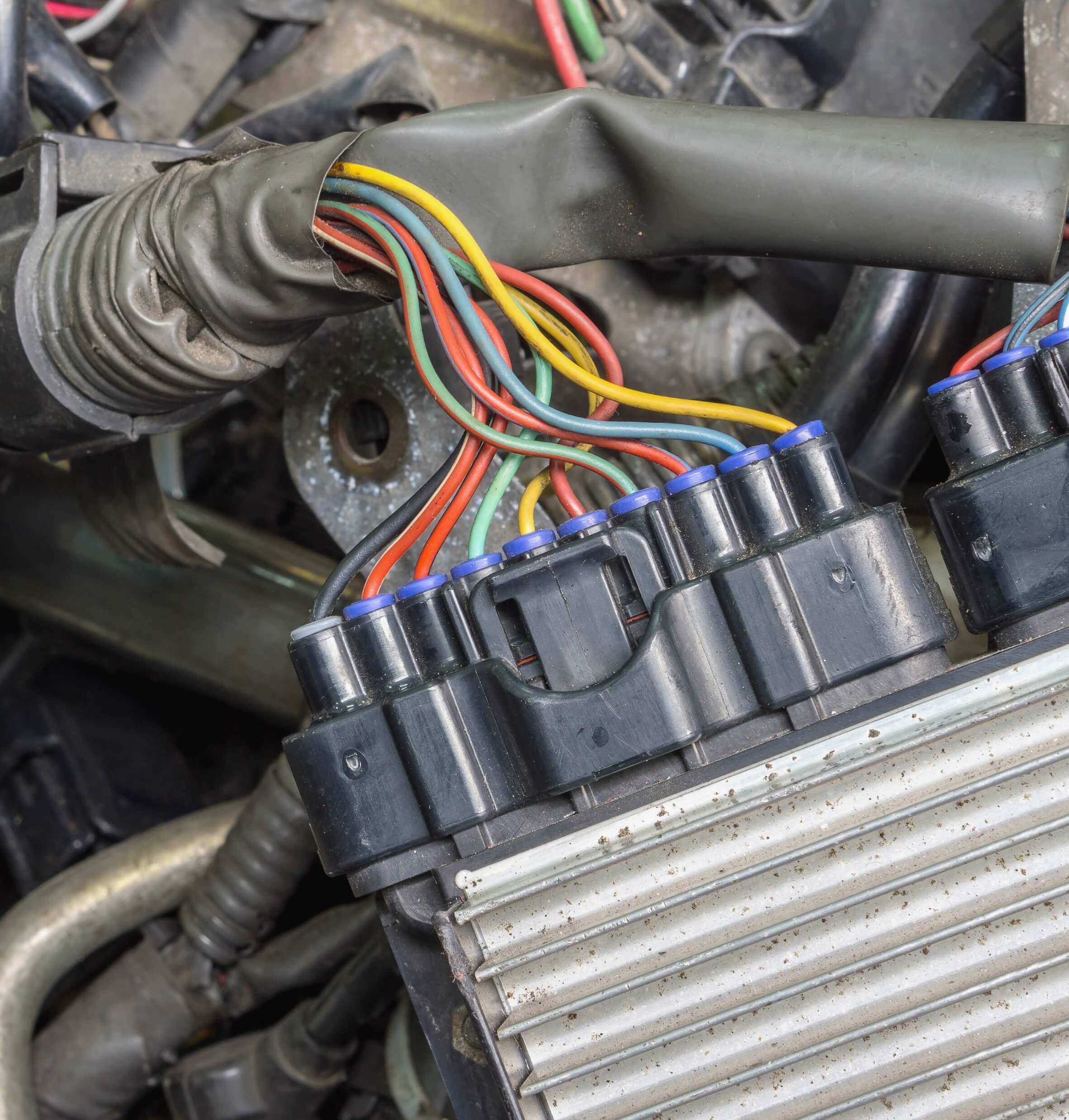

STATIC SPARK

Without a functioning spark plug, the engine won’t run. Static spark testing allows us to isolate a firing circuit to check timing and analyze its characteristics.

WIRE HARNESS

The wire harness is essential for relaying both electrical power and critical sensor data throughout the vehicle. Our advanced signature analysis allows testers to run both hot and cold validations and characterizations of engine wiring circuits.

CAMSHAFT

Engine camshaft validation checks for out-of-specification lobes, incorrect cam functioning, and other cam defects that can affect engine performance. We run both hot and cold tests to provide characterization of the camshaft.

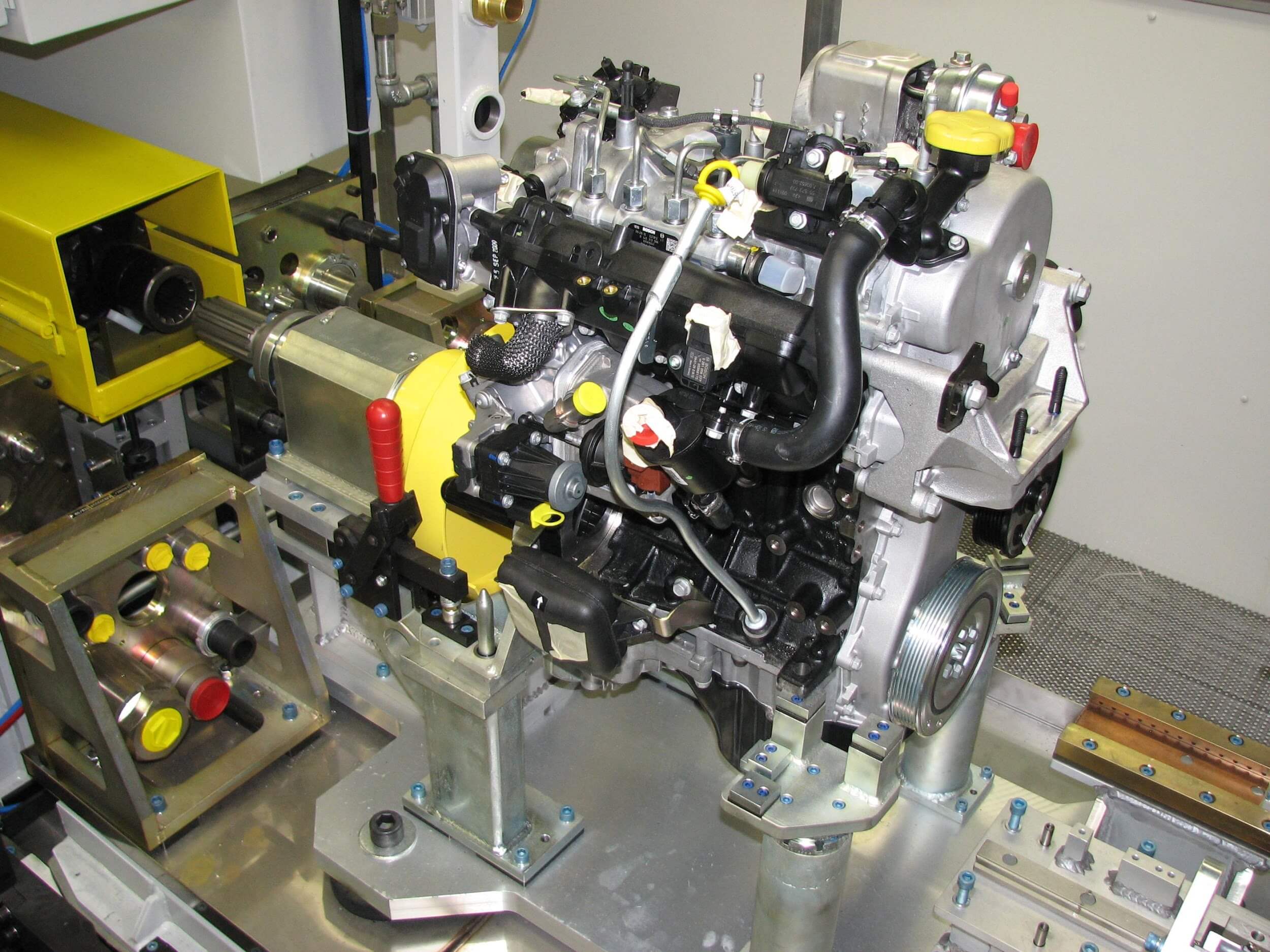

TTT/NO PISTONS

We use dynamic torque-to-turn evaluations to check for possible issues with the crankshaft prior to full motor assembly. This allows us to check for binding errors, bent shafts, or even missing bearings.

TTTw/PISTONS

Torque-to-turn tests including pistons are essential to be sure that the final engine assembly meets quality control standards. We use a combination of our advanced signature analysis along with torque signals and NVH probes to validate short block assemblies.

NVH

We measure NVH characterizations using dynamic torque, linear acceleration, and dynamic

angular acceleration to certify engines meet design specifications. When necessary, our advanced testing tools include laser vibrometers and microphone arrays to help characterize dynamic noise from the motor.

GET TO KNOW EAGLE TECHNOLOGIES

Lets Talk.

Contact us and we’ll be happy to help!