Furniture and appliances are the objects we engage with most during our day, whether they are the beds we sleep on, the chairs we sit on to work, or the tools we use to prepare our meals. Manufacturers of these products want to deliver quality goods to consumers that will deserve the central place they fill in their homes.

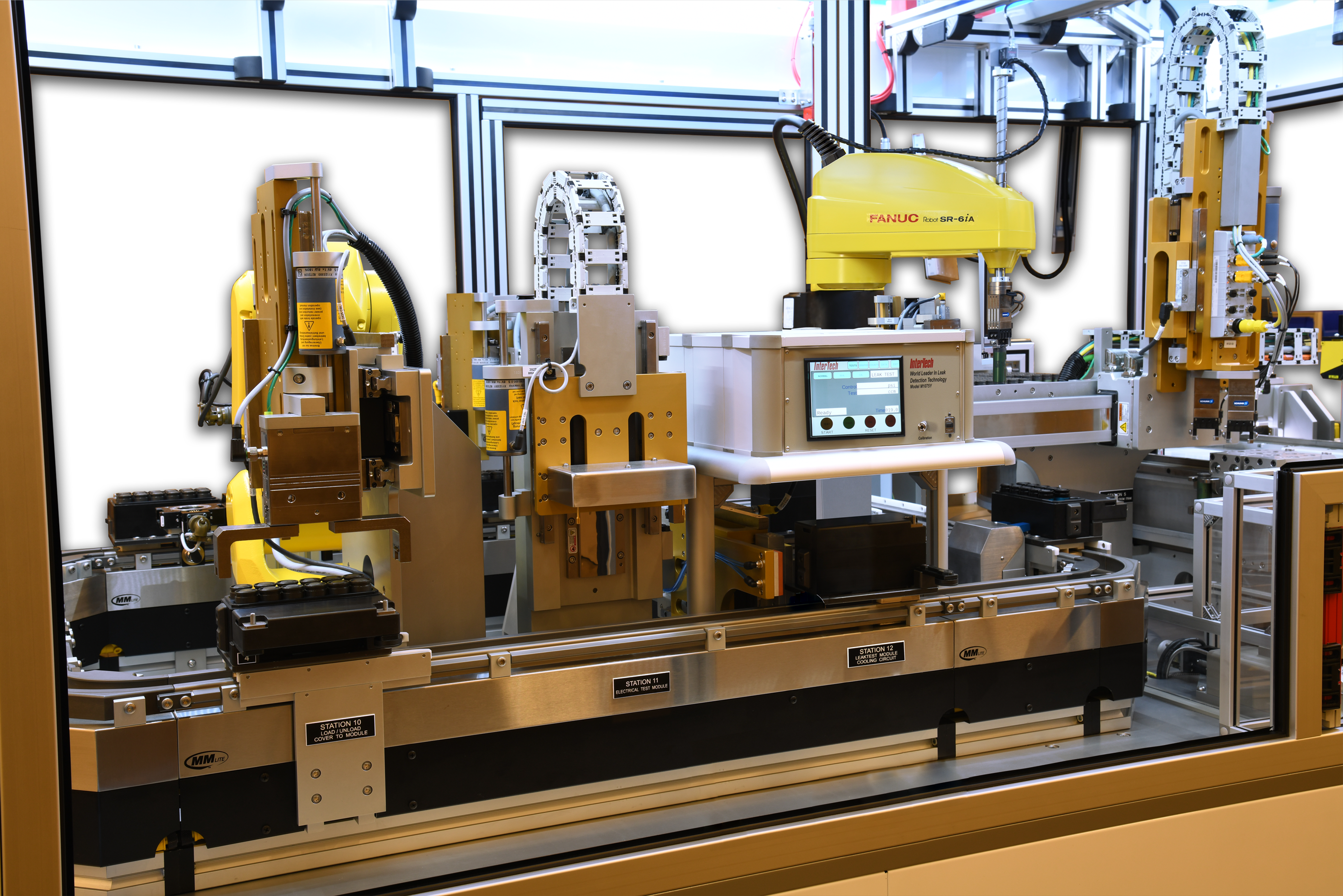

We have designed machines with the power to lift concrete floor tiles and the delicacy to assemble complex electronics. We can dispense adhesives and friction seal balance rings, stack products and load them onto pallets for shipping. Talk to us about your product, and we’ll manufacture a machine that can assemble it from start to finish.

FURNITURE MANUFACTURING

The furniture industry poses many challenges from material handling, product variation, process variation and volume fluctuation. Whether it is designing and manufacturing a system to handle concrete floor tiles, office partition panels, complex chairs or the stacking of finished goods Eagle has the experience in the furniture industry to meet your needs.

Our automation processes, which include adhesive dispensing, welding, stamped pan handling, stacking/de-stacking, and assembly, are just a few of the furniture industry challenges that Eagle has encountered and conquered. Let us show you how we can help solve your challenge.

BUILDING

Construction details that go into homes may need to be built to spec, but that doesn’t mean automation plays no role. Today’s automated processes can handle customization, so that customers ordering windows, doors, or kitchen cabinetry can still benefit from the higher quality and lower costs of automation.

For instance, automated systems can be used to apply sealants to countertops, cut materials to proportion for framing doors, or assemble a patented locking system for a window. Automation can also assist with packaging and transporting finished products once they’re ready to be shipped.

HOME APPLIANCE

Anyone who’s had a cheap home appliance break unexpectedly has probably lamented that “they don’t make them how the used to.” And in a way, they’re right: we’re here to help manufacturers make them better. Whether that means developing higher-quality production methods, or helping to incorporate new technology into smart devices, we have the expertise to see the job done right.

For instance, when America’s largest manufacturer of washers and dryers needs balance rings, Eagle Technologies was chosen to produce machines capable of friction welding these large diameter plastic parts together quickly and with little to no scrap. Our experience with this material joining method helped them deliver better products to their customers.