Our friction welding designs require fewer machine components to assemble, and require less build-out time. Because the joint is created using friction, no other filler metals are required, saving costs on raw materials. The elimination of a fuel source makes it an eco-friendly method, while also reducing harmful fumes.

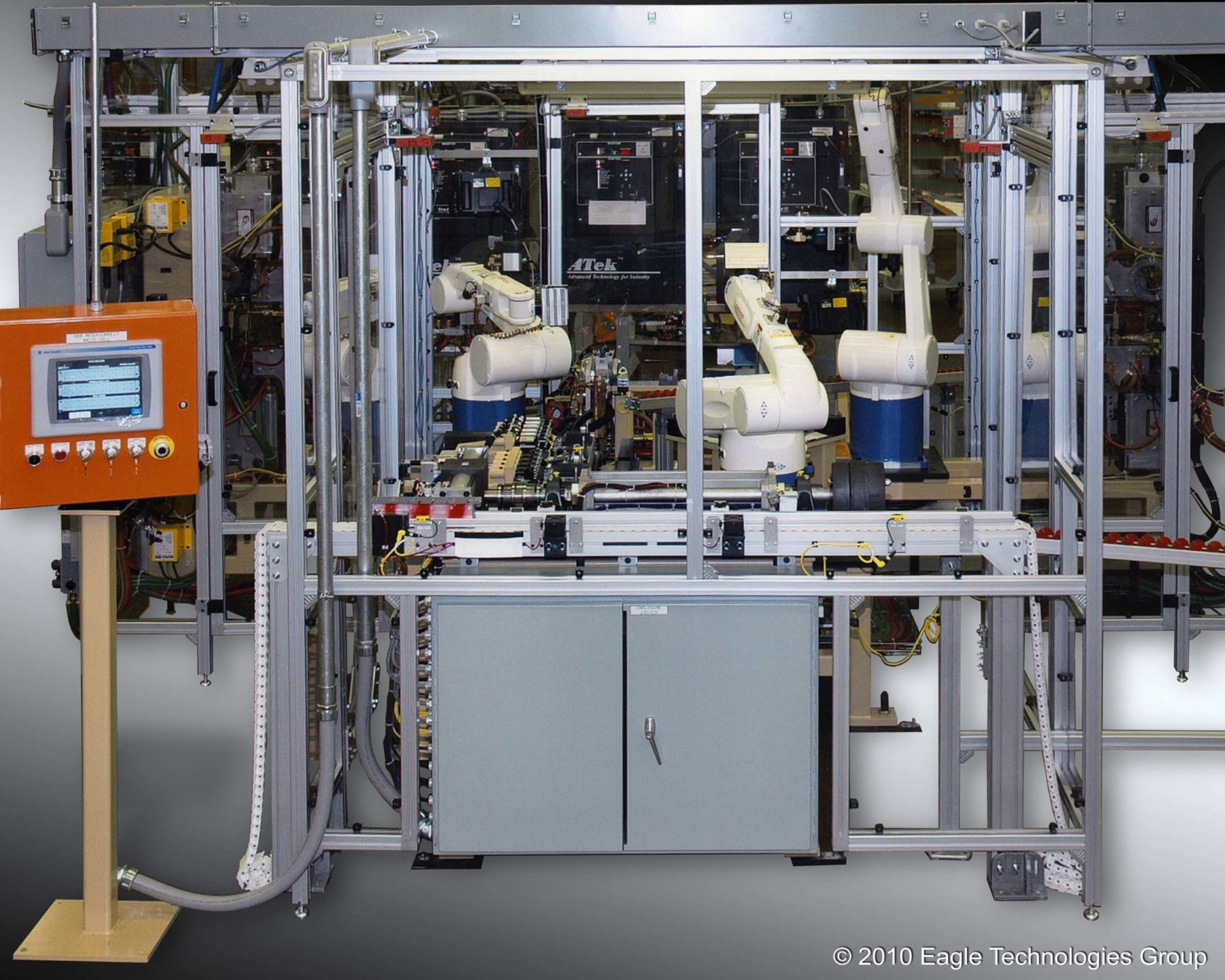

Friction welding is a preferred method for many industrial parts, including jet engine turbines, driveline assemblies, and hydraulic piston rods. We have experience incorporating this technique into a range of automations, and can work with your engineering team to find the right application for your situation.

OUR FRICTION WELDING TECHNOLOGIES INCLUDE:

- IndraMotion MLD platform with integrated motion logic control

- IndraDrive digital intelligent servo drives with Safety on Board and Safe Motion functionality

- Synchronous IndraDyn servo motor with absolute Hiperface encoder

- SERCOS III Ethernet

- Durable Ball Screw and Ball Rail® assemblies

- VCP Series touchscreen HMI

Lets Talk.

Contact us and we’ll be happy to help!