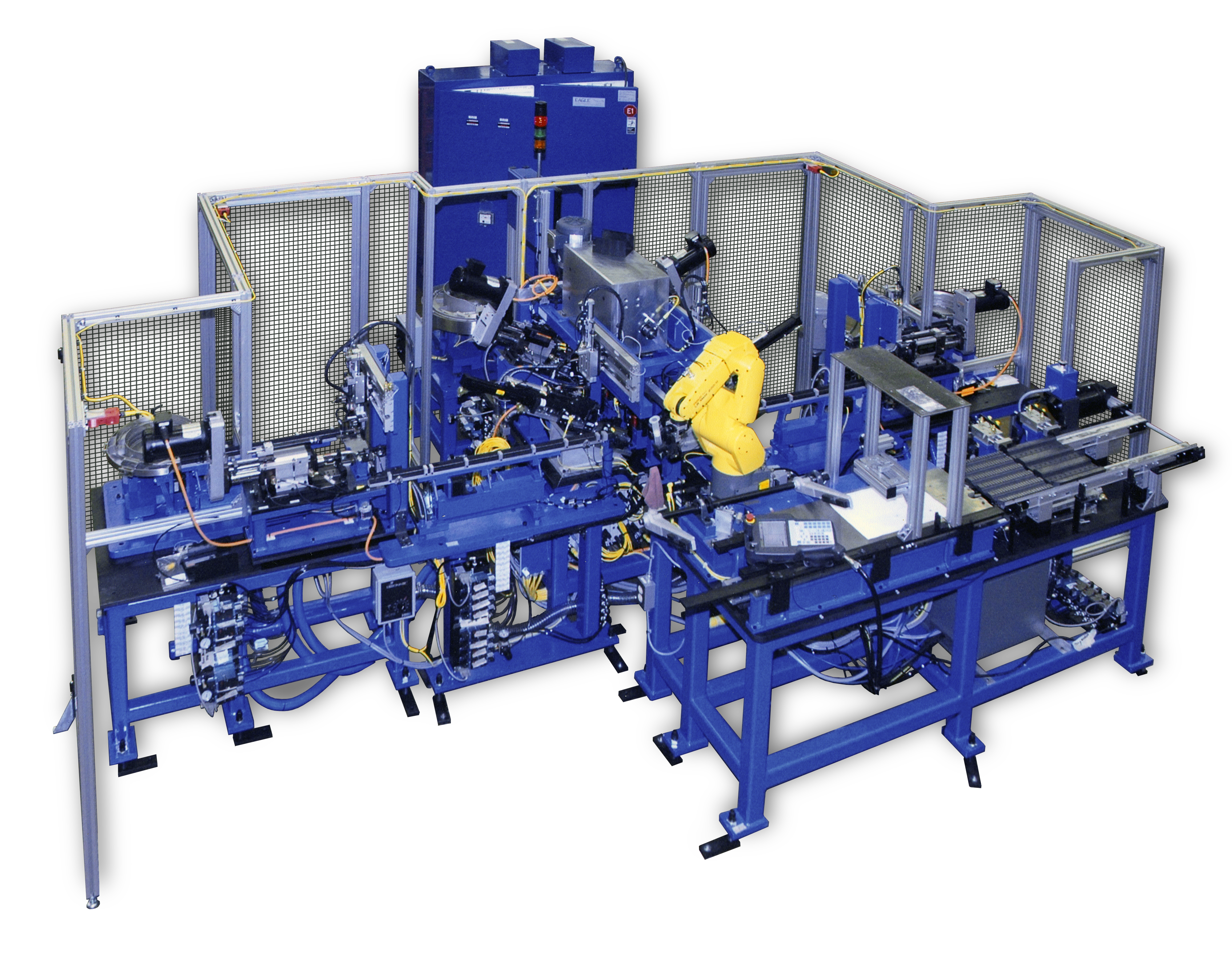

Our experience with fuel system assembly encompasses a range of manufacturing techniques which we adapt to customer need. These automation technologies, including laser welding, pressing, and swaging, can reliably produce fuel system components with fit tolerances down to a fraction of a micron.

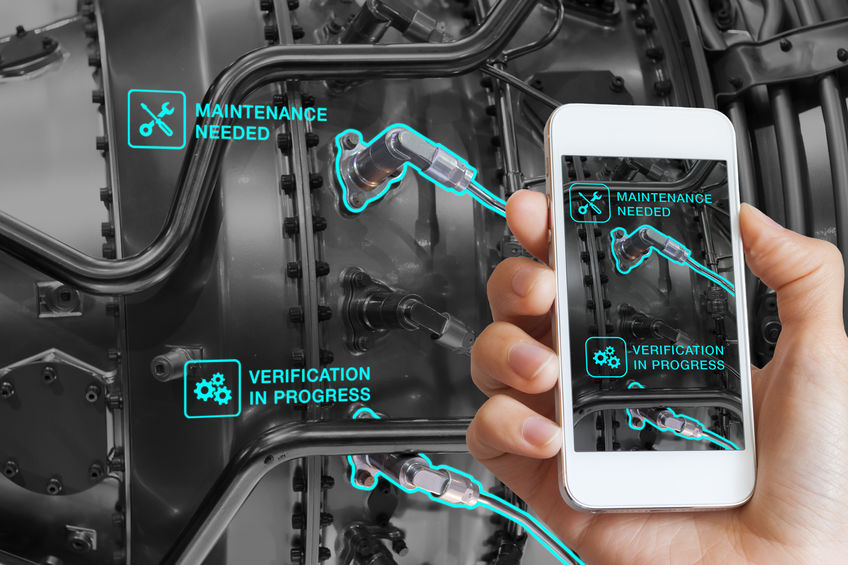

We match our assembly processes with both in-line and end-of-line validation. These include leak and valve tests, functional testing, and verification of all fuel system sensors. Using Industry 4.0 technologies, we can track components throughout the production process, and incorporate AR devices to help operators identify parts that have failed testing.

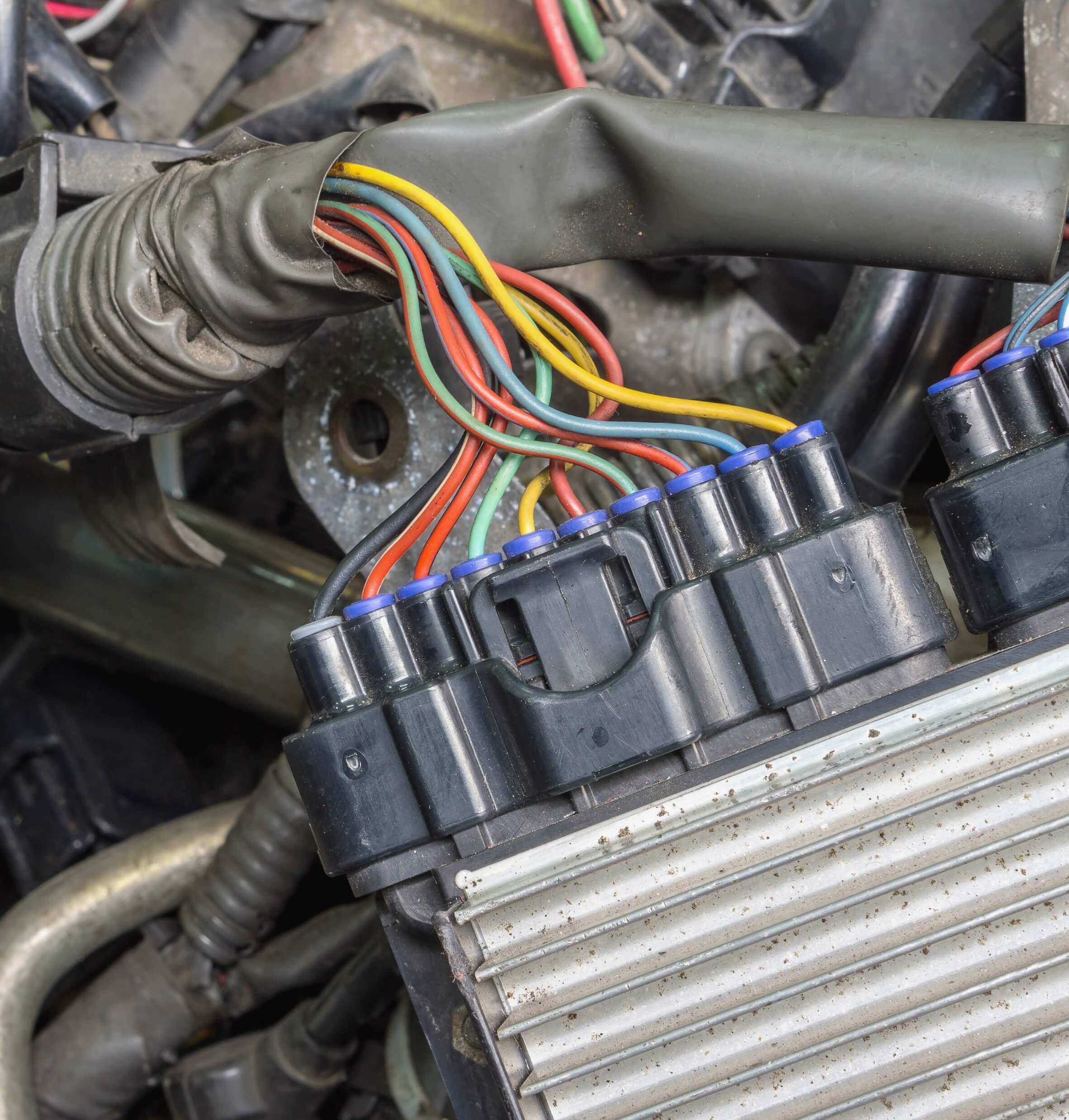

OUR EXPERTISE IN FUEL SYSTEM ASSEMBLY AND TEST INCLUDES:

- Injector – Gas & Diesel

- Mass Air Flow Sensor

- Pressure Sensor

- Pump

- Oxygen Sensor

- Oil Rail

- Regulator

- Tank

Lets Talk.

Contact us and we’ll be happy to help!