Our job is to choose the right sensor to measure the right measurement to report the right data. By conducting end-of-line testing, we can identify potential production failures before they reach consumers, saving businesses hundreds of thousands of dollars in costly recalls that damage the bottom line and lead to tarnished reputations.

We are not satisfied by passing tests under perfect lab conditions. Rather, we bring our testing equipment into the field, to each manufacturing plant, so that we can run correlation tests that show our machines achieve the same high production standards as the baseline no matter where they are deployed.

CORE CAPABILITIES

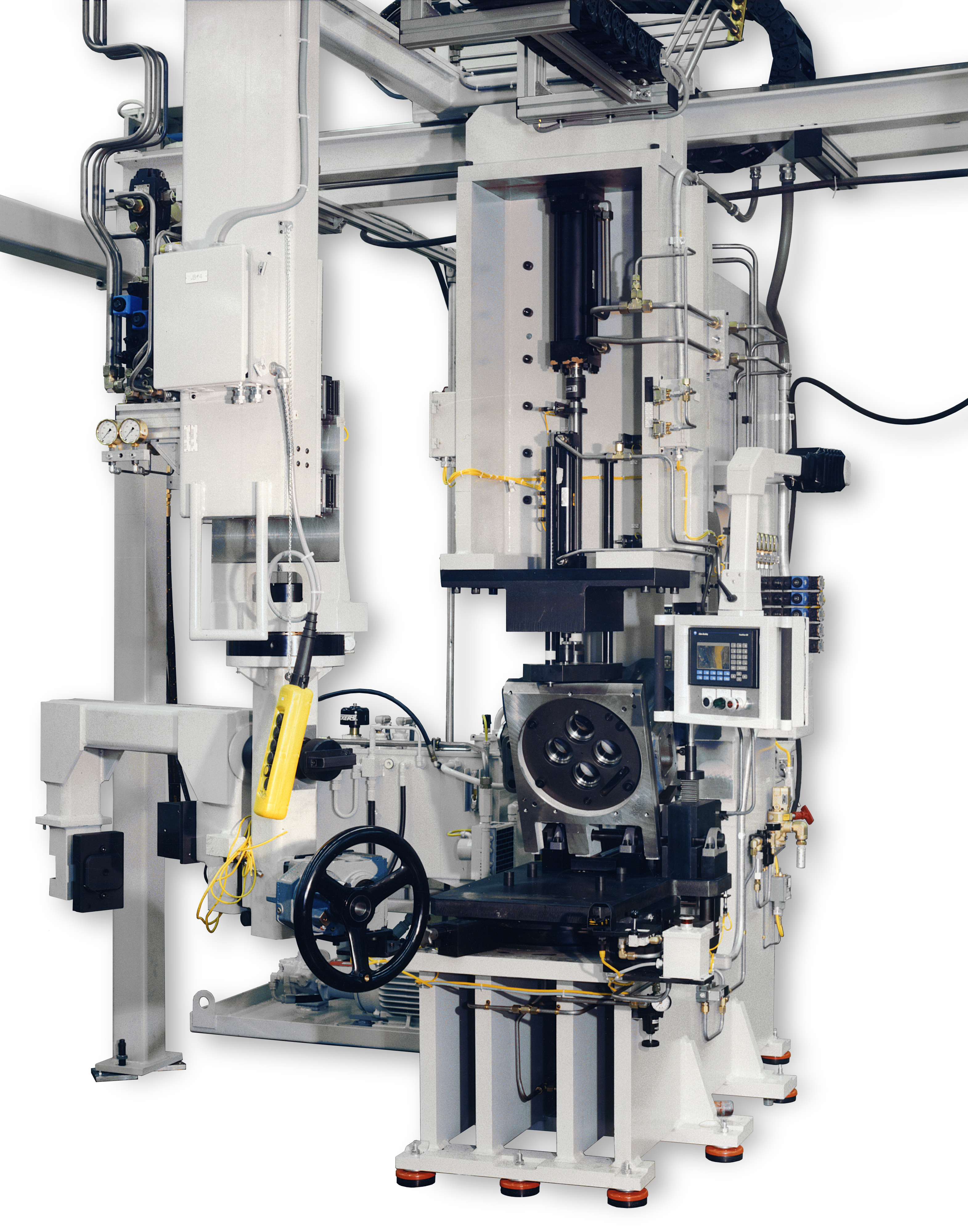

Mechanical concept, design, and build for product test configurations; axle, transmission, trans-axle, engine, PTO, and EV/EV battery systems.

• 3D Design and FEA

• Modeling validation using SolidWorks, MSC or ADAMS.

• NVH design validation & stress/strain validation to insure robust machine designs.

Controls concept, design, and complete panel build along with test pod (test computer/UPS/hardware/CAN BUS).

• Test Software Design & Support (NI LabVIEW, NI TestStand, DISCOM, BauerControls, WMA, AB Plato, other)

• PLC (Allen Bradley, Siemens, Mitsubishi, Omron)

• Drives/Motors (Rockwell, Rexroth, Siemens, Yaskawa, Unico, KEB, ABB)

• Serial/Digital Controllers (VECTOR CANape, other)

IMPROVED RELIABILITY THROUGH MANUFACTURING VALIDATION

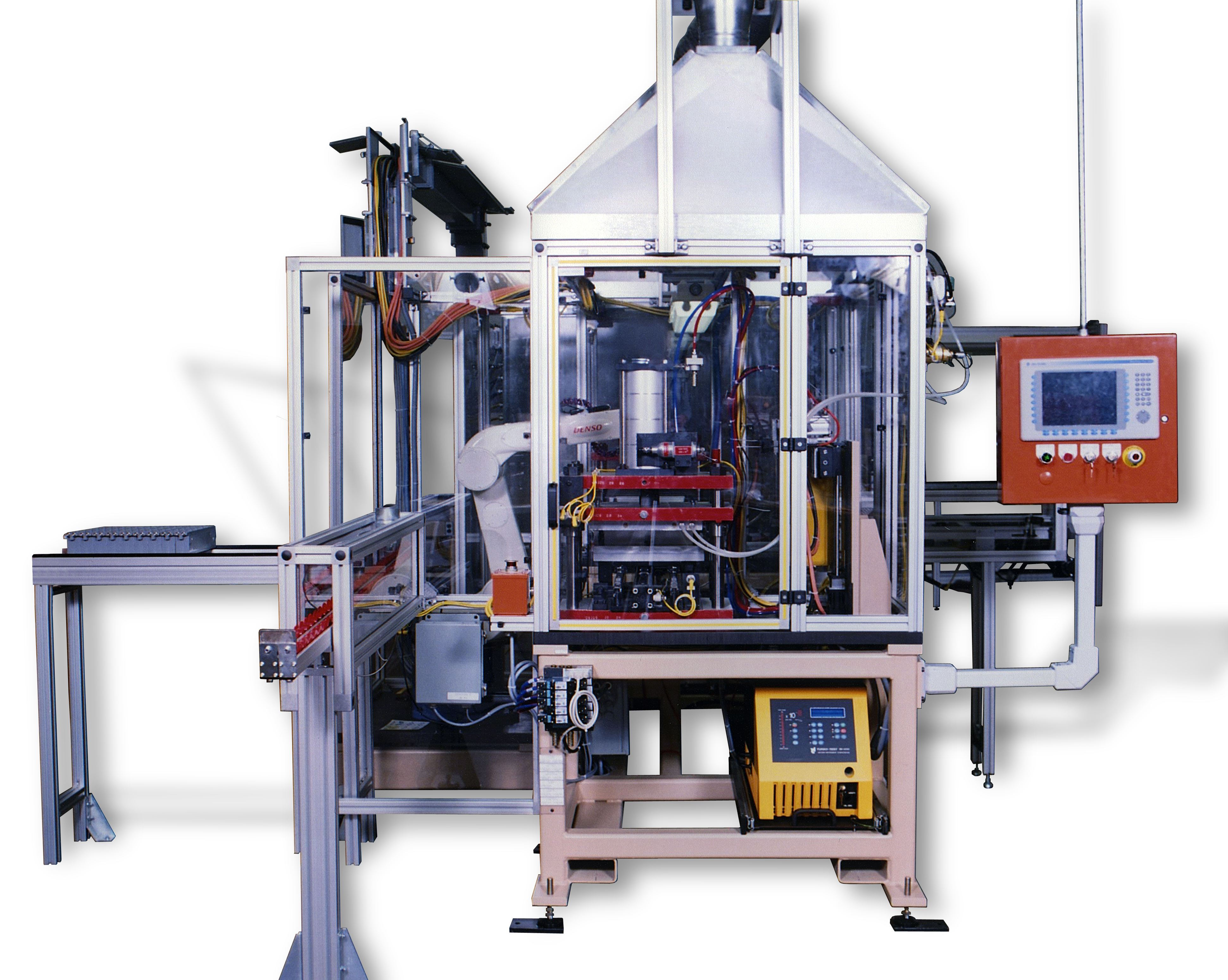

Validation and assembly processes are proven cost savers for businesses. These additional quality control measures mean businesses are able to reduce scrap and rework costs and reduce expensive product recalls linked to manufacturing flaws.

• AIR VERIFICATION: Using compressed air, we gather precise and reliable testing data about product performance by means of an inherently clean medium.

• VISION VERIFICATION: For applications that involve multiple model verification or changing component environments, we integrate a robot vision inspection station to save costs.

• GAUGING AND MEASUREMENT: We use results from our measurements to dynamically adjust the assembly process, thereby reducing the costs of Work in Process (WIP).

• ROBOTIC GAUGING VALIDATION: When applicable, we use advanced robotics with highly accurate vision and laser measurement devices as a flexible way to cover many products.

ELECTRIC VEHICLES

In the past decade, innovations in fuel cell technology, autonomous driving, and rapid charging have transformed the electric vehicle market. To maintain the rapid pace of development, EV manufacturers depend on the high-level testing we provide.

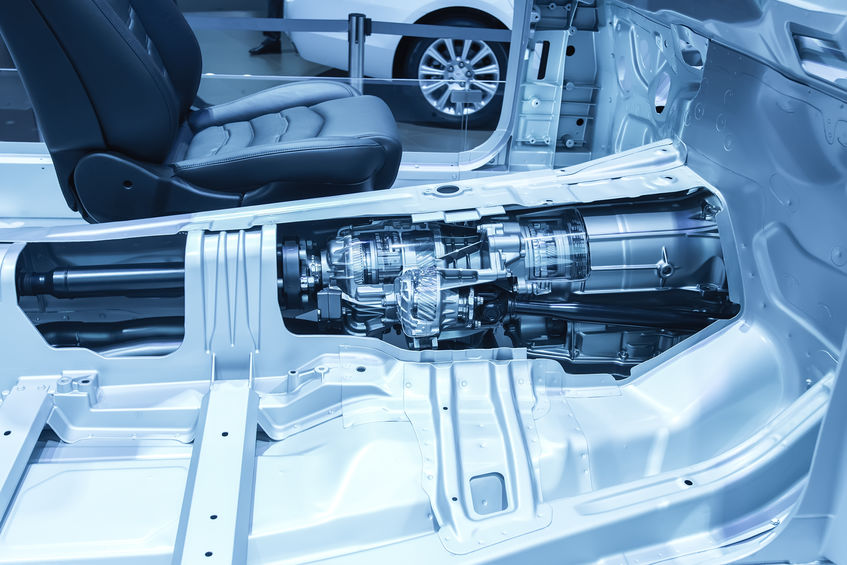

TRANSMISSIONS

The transmission transfers energy from the engine through the powertrain, meaning their performance has a direct impact on engine efficiency. From manual to automatic, multi-speed to dual clutch, we can test your transmission systems to ensure peak performance.

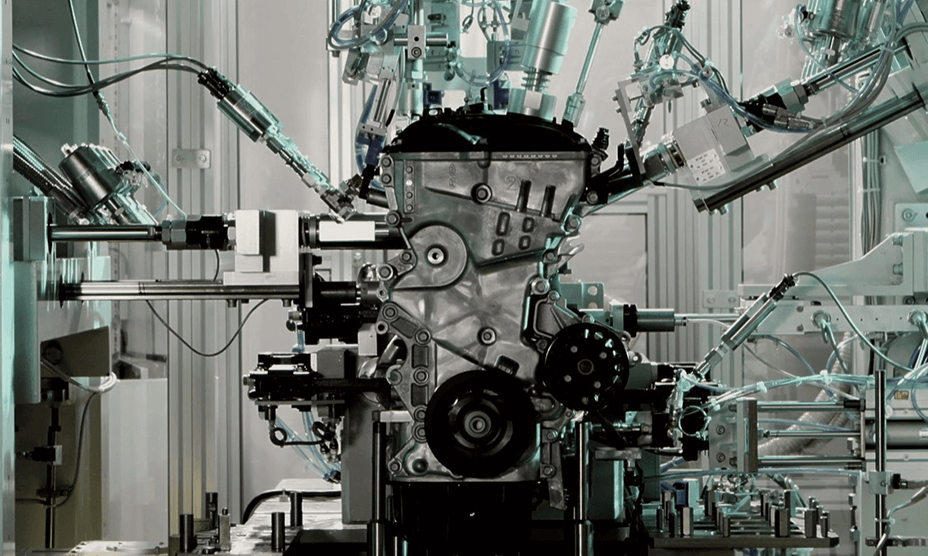

ENGINES

Despite recent investments in EV technology, the combustion engine remains the most common choice for automotive applications. Yet advances in design and engineering make it far from traditional. Let us help you achieve the next big step forward.

LIFE SCIENCES

Advances in medical technology have revolutionized modern medicine, offering new procedures, treatments, and medical devices to hospitals and patients. Our advanced testing systems help these products reach the market quickly and safely.

AEROSPACE / MILITARY

Aerospace and military technologies represent a class of high-tech products that must operate under conditions far beyond everyday applications. Our test systems ensure that they measure up.

PRODUCT TESTING

We can create custom product test scenarios for almost any situation. If you need your final product to withstand certain boundary conditions, we can build our procedures around those limits and create a repeatable test that your team can perform to ensure product quality.

SPECIAL DESIGNS

• Time/Frequency/Order Domain Analysis (NICK, Torque to Turn, Backlash, other)

• Angular Based Analysis (Dynamic torque/Angular Acceleration)

• Leak Test/Mass Spec

• Vision Systems (Area Scan-Line Scan)

• Integrated Robotic Systems Supporting EOLT / Final Test